Preparation of Tungsten Disulfide Transverse Heterojunction

- Details

- Category: Tungsten Information

- Published on Wednesday, 25 July 2018 18:09

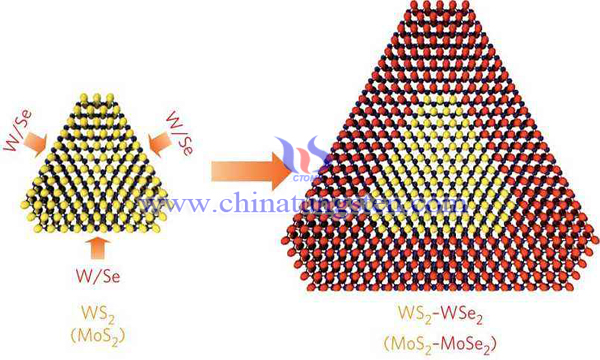

Heterojunctions have become an essential element of the modern semiconductor industry, and they play an important role in high-speed electronic devices and optoelectronic devices. Two-dimensional layered materials, including graphene and transition metal disulfide, can serve as a constituent unit of a heterostructure due to their unique electrical and optical properties.

Transverse heterojunctions are formed by the covalent bonding of two materials. Due to their simple preparation, they have greater potential for application in bandgap engineering. However, most of the current research has focused on vertical heterojunctions, and large-scale preparation of two-dimensional transverse l heterojunctions remains a challenge. This paper introduces a two-dimensional tungsten disulfide/tungsten trioxide transverse heterojunction and its preparation method. The contents are as follows:

Method for preparing two-dimensional tungsten disulfide/tungsten trioxide lateral heterojunction: dispersing 50-100 parts by mass of tungsten disulfide in 5-10 parts by volume of water or ethanol, and then placing the dispersion In a supercritical carbon dioxide reaction apparatus, the reaction is stirred at 40-45 ° C, 6-20 MPa for 0.5-7 h, after the reaction is completed, the pressure is released to normal pressure, and the obtained reaction liquid is removed from the unpeeled tungsten disulfide, and then placed in the air. Medium oxidation (the solution is dark green after oxidation, light yellow or bright yellow after oxidation), and the solvent in the solution after oxidation is removed to obtain a two-dimensional tungsten disulfide/tungsten trioxide lateral heterojunction; the above mass parts are In mg, the volume is in mL.

To be more specific:

Dissolve 100 mg WS2 in 10 ml of deionized water, soon the prepared solution in a cold water bath (10 ° C) at 240 W for 2 h, so that WS2 is evenly mixed in the solution; transfer the solution after ultrasonic 2 h to 50 ml. In the autoclave, the reaction vessel is filled with carbon dioxide, and the flow rate of carbon dioxide is 150 ml/h, so that the solution is kept under the condition of 40 ° C and 16 MPa for 3 h, and the solution is magnetically stirred to make the solution and super The critical carbon dioxide is fully contacted. After the reaction, the carbon dioxide in the reaction vessel is slowly evacuated in 1 h; the reaction liquid in the reaction vessel is taken out, and ultrasonicated in a cold water bath (10 ° C) at 240 W for 2 h; then at 3000 rpm/min, Centrifuge the reaction solution under 15 min, take the upper layer, place it in the air for 12 h (the solution is dark green before oxidation, the solution is light yellow after oxidation), remove the solvent from the oxidized solution to obtain two-dimensional tungsten disulfide / Transverse heterojunction of tungsten trioxide monohydrate.

The method solves the problem of large-scale preparation of two-dimensional transverse heterojunction at present, and realizes one-step completion of high-yield and high-quality preparation of two-dimensional transverse heterojunction structure of tungsten disulfide. The method is simple and easy, the raw materials are cheap and easy to obtain, environmental friendly and pollution-free, and the appearance of heterostructures makes the electron-hole pairs separate, which makes them have good development prospects in the fields of photocatalytic degradation of organic compounds and photocatalytic hydrogen production.

- Tungsten Manufacturer & Supplier, Chinatungsten Online: www.chinatungsten.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com