Comprehensive Treatment of Tungsten-containing Fluorogypsum

- Details

- Category: Tungsten Information

- Published on Wednesday, 24 October 2018 21:17

About 7% of fluorite is associated with Scheelite in China. The flotation properties of scheelite and fluorite are similar, and scheelite is often found in floatation fluorite concentrate. Tungsten containing fluorite concentrate is obtained from fluorine containing gypsum by dry fluorine process. At present, the slag is mainly sold to cement factories or used to prepare gypsum slabs. Calcium and sulfur in the slag are only treated as low-end gypsum, and no high value-added products are produced. Tungsten is not used at all. White white is losing valuable resources.

Tungsten Hexafluoride Scale Manufacturing

- Details

- Category: Tungsten Information

- Published on Wednesday, 24 October 2018 21:00

Tungsten hexafluoride (WF6), colorless gas or light yellow liquid, solid is easy to deliquescent white crystals, smoke in humid air. Tungsten hexafluoride is a kind of tungsten fluoride which is used in the chemical evaporation of tungsten and as a fluoride agent. It can be reduced to tungsten and HF by hydrogen and other reducing gases at high temperature.

Taiwan Tech University Prepared Nanofiber Membranes Through New Technologies Successfully

- Details

- Category: Tungsten Information

- Published on Wednesday, 24 October 2018 09:35

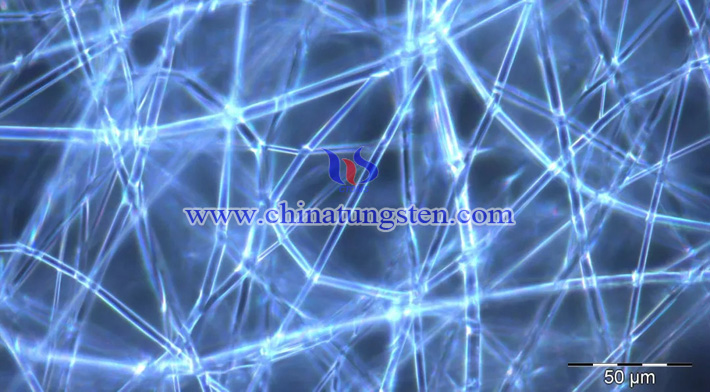

Recently, researchers at the University of Science and Technology of Taiwan successfully fabricated a nanofiber membrane, a purple tungsten oxide/polylactic acid fiber membrane (WWO2.72/PLA), through a novel nanometer to submicron ultrafine fiber processing method.

We all know that solar energy is a clean energy source, and it is inexhaustible. According to statistics, the energy consumption in the world for one year is only equivalent to the solar energy that hits the earth on a day. In other words, sunlight provides us with enough renewable energy. Not only that, but the potential of sunlight is converted into heat. Therefore, solar energy is widely used for residential heating, seawater desalination, sewage treatment, and steam generation. However, materials that are inexpensive and have high photothermal conversion efficiency need to be explored. In other words, the development and preparation of photothermal materials still faces many challenges.

All in all, the development of efficient photothermal materials is a very important issue. Only by solving this problem can we obtain a photothermal material with higher solar-thermal conversion efficiency and more efficient water evaporation performance.

Therefore, recently, the Taiwan University of Science and Technology has sent good news. Their researchers have successfully prepared a nanofiber membrane - mainly obtained by melt electrospinning to reduce tungsten oxide / polylactic acid. Among them, the tungsten oxide used is purple tungsten oxide, a metal oxide having a strong near-infrared (NIR) light absorbing ability. Therefore, there is no doubt that the NIR photothermal conversion performance of the obtained nanofiber membrane is improved.

Based on this, the researchers incorporated the nano-violet tungsten oxide particles into a polylactic acid matrix by melt processing, and then extruded the composite into a wire using a single screw extruder. Thereafter, a fiber membrane was prepared from the extrusion line of the purple tungsten oxide/polylactic acid composite by melt electrospinning. It must be said that the cost of preparing nanofiber membranes by the technique of melt electrospinning is low and effective. In addition, this process does not add chemicals to the harmful environment, which is conducive to environmental protection.

Then, the researchers applied the resulting fiber membranes to practice. They applied a molten electrospun purple tungsten oxide/polylactic acid fiber membrane design with surface hydrophobicity and floating on water to the steam generation based on the solar heating interface concept. The results of the practice show that the water evaporation efficiency of the photothermal fiber membrane containing the purple tungsten oxide nanoparticles (7 wt%) is about 81% higher than that of the pure polylactic acid fiber membrane (PLA fiber membrane). The results of this study provide the idea for the development of a new type of photothermal fiber membrane, that is, the development of a new type of photothermal fiber membrane that enhances the performance of light-driven water evaporation, making it effective for water treatment and desalination.

We must first understand what is electrospinning? Moreover, there are many techniques for preparing ultrafine fibers at present. Among them, electrospinning (electrospinning) is a new processing method capable of continuously and rapidly preparing nanometer to submicron ultrafine fibers. In recent years, people have been very concerned about it. Because, in theory, any polymer material that can be melted or dissolved can be electrospun, not just PLA, but also other such as nylon, polyurethane, polyoxyethylene, polyacrylonitrile, polyaluminum. Polymers such as amines, polyvinyl alcohols, and polycaprolactones are also acceptable. Of course, the reason why electrospinning has been highly valued in recent years is thanks to the development of nanotechnology.

Melt electrospinning is a method of electrospinning. Another electrospinning method is solution electrospinning. At present, the solution electrospinning technology is very mature, but there are problems such as low production efficiency, solvent recovery, and emission pollution. In contrast, melt electrospinning is considered to be a more economical, environmentally friendly, and safer electrospinning technique because it does not require the addition of any solvents, is environmentally friendly, and produces a smooth fiber surface. No flaws, and high production efficiency. Because of the characteristics of the process itself, the melt electrospinning technology has been applied in the fields of filtration protection, biomedicine and energy storage packaging.

We should be grateful to the hard work of a generation of photothermal materials researchers, who let light and thermal materials and nanotechnology not only be materials and technology, but a combination of the two and even more.

- Tungsten Manufacturer & Supplier, Chinatungsten Online: www.chinatungsten.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

Tungsten Carbide Ring Can Be Self-defense, Break The Window to Escape

- Details

- Category: Tungsten Information

- Published on Tuesday, 23 October 2018 09:34

We all know that from a rational point of view, tungsten carbide ring can be used as decorations; from a perceptual point of view, tungsten carbide ring is not just decorations, because it can add a bit of personality and fashion sense to the trend. Not only that, the specially designed tungsten carbide ring can also be used for self-defense. Moreover, this hard, diamond-like ring can also be used to break the window and escape. In the end, the "black technology" application of this tungsten carbide ring will be revealed.

Our Army 99 Tanks Battled The "Oriental-2018" Exercise Successful

- Details

- Category: Tungsten Information

- Published on Monday, 22 October 2018 11:02

According to the news released by the Ministry of National Defense of the People's Republic of China, the Russian "Oriental-2018" strategic exercise that was invited to participate in this military is the largest strategic exercise organized by the Russian military in recent years. This time is also the largest outbound performance in the history of our military. Our army has a military force of about 3,200 troops, and has invested more than 1,000 vehicles including 99 tanks, 30 fixed-wing aircraft and helicopters.

The content of this exercise has been expanded from the previous "joint anti-terrorism" to traditional security issues such as "organizing joint defense and counterattack". Compared with the previous "Peace Mission" exercise, this time the strategic exercise level is higher, the scale is larger, the elements are more complete, and the unity is higher - marking the level of political strategic mutual trust and military cooperation between China and Russia reaching a record high.

The Sino-Russian joint military exercise was staged at the Russian training ground in Chugor. At the time of the golden autumn, the Chugor grassland presents a scene of high altitude. "The ground iron armor broke into the air" and "the air warplane roared". This scene was carried out almost simultaneously, adding a lot of "fireworks" to Chugor.

In this exercise, a series of heavyweight "star" equipment of our army were all stunningly displayed. Among them, the domestic 99 improved main battle tank was the most eye-catching. So, let's take a look at the things of our Army's 99-type main battle tank.

We learned from the Internet that the comprehensive performance of the 99-type main battle tank reached the mainstream level of the international third-generation main battle tank. The debut of the 99 tanks was on the National Day parade in the 50th anniversary of the founding of the People's Republic of China in 1991. It also participated in the military parade of the 60th anniversary of the founding of the People's Republic of China. It has also appeared in the Sino-Russian joint military exercise many times.

The Type 99 main battle tank is equipped with the latest domestic 125mm smoothbore gun, automatic loader, advanced command fire control system and high-powered engine. It can launch three different types of shells - tungsten alloy tail stabilizer shelling armor-piercing projectile , armor-piercing ammunition and grenades. It emits the third generation of long-diameter tungsten alloy tail stabilizers, and the initial speed is up to 1,780 meters per second. Moreover, it can penetrate 850 mm thick at a distance of two kilometers. Homogeneous armor.

It is reported that the Type 99 main battle tank is equivalent in firepower to the M1A2 and Leopard 2A6. Our Army's Type 99 tanks are available in basic, first-stage, second-stage, and third-stage (99A) models. One of the main ways to distinguish the Type 99 tank model is to look at the turret. He said: "The 99 main battle tanks use welded turrets. Since then, improvements have been made to improve the turrets to improve tank protection, so we can distinguish the different types of tanks according to turret changes."

He also said: "The basic turret of the 99 main battle tank is best identified. It is a square turret. From the front, it is more similar to the M1 main battle tank. The first phase of the 99 main battle tank is a tapered wedge turret. Compared with the basic type, the biggest change is to add additional armor in the tank turret and the car body. The 99 main battle tank is improved in the second phase, and compared with the first-stage improvement type, the parallel machine gun leaves less blank space. 99A, Still a mystery."

This time, the main battle tank that our army participated in was not the 99A modified tank that many people thought, but it should be the 99 second-stage improved main battle tank. Of course, the 99-stage modified tank also showed the overall performance of the T-72B3 main battle tank superior to the Russian military in the exercise, although it is not the latest main battle tank of our army.

For example, the Russian T-72B3 tank captain is not equipped with a night vision system, only the gunner is equipped, so the captain needs to obtain images from the gunner night vision system. From this point of view, the battlefield situational awareness of the 99th phase of the improved tank is better than that of the T-72B3 tank. It is equipped with a vehicle-length day and night observation mirror, so that the captain can independently observe the battlefield situation and instruct the gunner to strike the target without much trouble.

Finally, let's take a look at the German "Focus" weekly website titled "The World's Strongest Tanks" ranking, ranking 10th to the first place for Ukraine's "Opirot", Russia's T-90 main battle tank Israel's "Meikava 4" main battle tank, France's Leclerc main battle tank, Japan's 10 main battle tank, South Korea's K-2 Panther main battle tank, Russia's T-14 Amata main battle Tanks, China's 99-type main battle tank, Germany's Leopard 2A7 main battle tank and the US M1A2 "Abrams".

- Tungsten Alloy Manufacturer & Supplier, Chinatungsten Online: www.tungsten-alloy.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

Electrochromic Devices Are Listed in Materials Horizons Developed by China

- Details

- Category: Tungsten Information

- Published on Friday, 19 October 2018 10:09

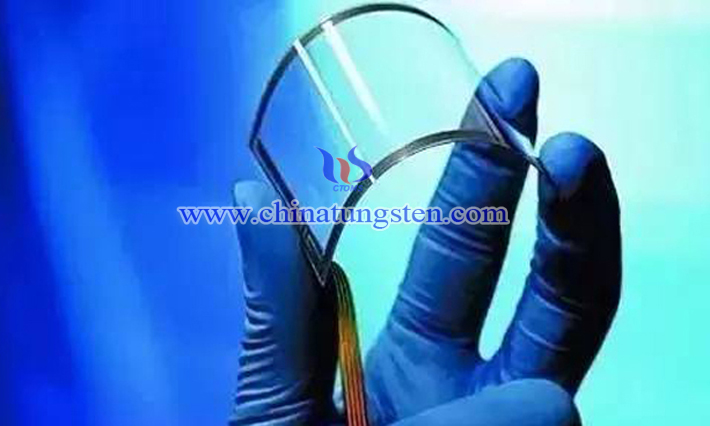

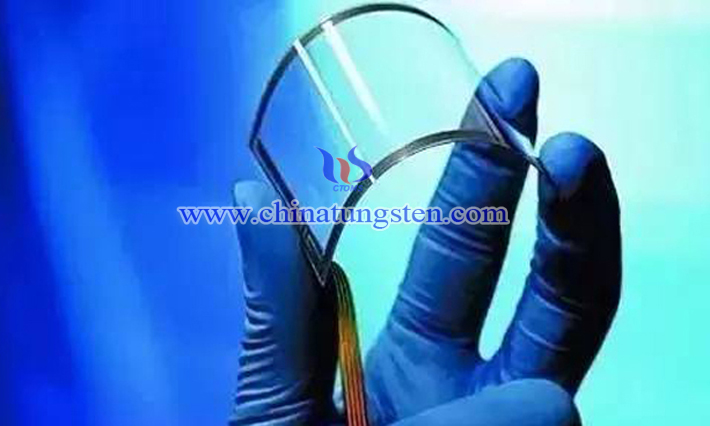

Recently, materials science researchers from Xi'an Jiaotong University, together with Southern University of Science and Technology and Pennsylvania State University, have designed a new electrochromic device with ionohydrogel with novel electrochromic layered structure. The research results have been published in the well-known journal "Materials Horizons" in the field of international materials. This research paper is entitled "Multifunctional Hydrogel Enables Extremely Simplified Electrochromic Devices for Smart Windows and Ionic Writing Boards". The research was supported by the National Natural Science Foundation, the Boxin Project, and the Xi'an Jiaotong University Analysis and Testing Sharing Center.

The novel electrochromic layered structure is obtained by compounding a multifunctional ion hydrogel with a tungsten oxide film. Only this step can effectively simplify the internal structure of the electrochromic device. In addition, ion-hydrogel-based electrochromic devices exhibit significant color changes and up to seventy percent transmittance modulation under periodic biasing. Compared with the traditional electrochromic device, it is found that the response speed and coloring efficiency of the novel electrochromic device are significantly improved. This means that the worldwide problem of electrochromic devices - no discoloration and slow discoloration - has been greatly improved.

Otherwise, researchers have demonstrated a rewritable ion writing pad based on the principle of electrochromic. This design breaks through the limitations of electrochromic display devices that are not erasable. Moreover, the drive voltage is as low as ~1V. This research result is not only important for the design and development of next-generation electrochromic devices. At the same time, it also provides a new way of thinking for the application of ionized hydrogels.

According to records, Newton was found to be gravitationally attracted by the apple. It can be seen that there is always a cause and effect in everything. The birth of new electrochromic devices is also true, and it has its historical background. This is to say that you are familiar with electrochromic materials and electrochromic devices. You know the fact that the structure of traditional electrochromic devices is more complicated. This not only increases the cost of production, but also severely limits the flexibility of the overall design of the device. In particular, the problem that the display content of the conventional electrochromic display cannot be arbitrarily updated after being packaged. Because the display content of such displays has been predetermined by the patterning process of the electrodes or electrochromic layers. It is precisely because of this reason that the scientific research results of "ion hydrogel new electrochromic device" have been obtained.

There are many electrochromic device applications around you, such as smart dimming glass, monitors, and auto anti-glare rearview mirrors. Not to mention the latter two applications, only smart dimming glass, it is gradually replacing LOW-E glass, and is widely used in high-end areas such as hotels, exhibition halls, automobiles, high-speed rail and landmark buildings. So, do you know what these so-called electrochromic devices are?

An electrochromic device is a functional device - a device made of an electrochromic material. So, what is an electrochromic color-changing material? Naturally, it is a material with electrochromic properties. Optical properties such as color and transmittance of electrochromic materials can undergo stable and reversible changes under the control of an external electric field. That is to say, these materials, in appearance, exhibit reversible changes in color and transparency.

Functional devices developed using electrochromic materials have been widely used in smart/energy-efficient buildings, information displays, and defense industries. For example, the Boeing 787 Dreamliner and many architectural glass walls already have applications for electrochromic devices. In the future, with the popularization of this new ion-hydrogel electrochromic device, electrochromic devices will have a wider application prospect. I hope that our country's cute and respectable materials researchers can continue to innovate, let our electrochromic devices go to the forefront of the world, and make our lives better.

- Tungsten Manufacturer & Supplier, Chinatungsten Online: www.chinatungsten.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

Tungsten Molybdenum Resource Country Issued New Mineral Strategy, Opened Up Mining Industry

- Details

- Category: Tungsten Information

- Published on Wednesday, 17 October 2018 14:59

You may know that Victoria is located on the southeast coast of Australia and is known as the “Garden State” and the “Australian Miniature”! However, you know that although the state is only three percent of Australia's land area, its GDP is more than a quarter of Australia's. It has to be said that part of the credit is its rich natural mineral resources, which provides a good foundation for the development of the Australian economy. Therefore, Australia can be said to be the country with the largest tungsten and molybdenum resources.

Tungsten Copper Throat Insert Helps Chinese Private Rockets Lift Off?

- Details

- Category: Tungsten Information

- Published on Wednesday, 17 October 2018 14:48

A few days ago, the Chinese private rocket, the "hyperbolic Z" rocket, was the first sub-orbital test. This is not the first time launch a space launch. In the earlier, another private company also successfully conducted a sounding rocket test, the first private commercial rocket in China. However, what do you know about tungsten copper throat inserts while knowing these messages? Whether the tungsten copper throat inserts help Chinese private rockets lift off?

We all know that the working environment of the rocket is very bad, especially the nozzle throat of the solid rocket engine. As a rocket fan, you may know that the solid rocket engine refers to a chemical rocket engine that uses solid propellant, which is also known as a solid propellant rocket engine. You may also know that there are many solid propellants, such as polyurethane, polybutadiene and so on. But do you know what is the tungsten copper throat insert?

Tungsten copper throat insert is the lining material of the nozzle of the solid rocket engine nozzle. It is made of tungsten copper composite material, which is a self-sweating cooling throat lining material. It meets the requirements of the throat insert. Which with resistant to high temperature, corrosion and wear, high hardness, light weight, ablation resistance, thermal mechanical shock resistance and so on.

According to statistics, between 65 and 75 percent of the rocket's thrust is accelerated by the throat of the nozzle to the speed of sound. This shows the importance of the throat insert to the rocket as a whole. However, the working environment of the nozzle throat is very bad. The temperature rise at the moment of ignition is about two thousand degrees Celsius per second, and the working temperature is also very high, usually about three thousand degrees Celsius. Therefore, the throat insert has a high requirement for the high temperature strength of its material. At a temperature of three thousand degrees Celsius or higher, the copper contained in the two-phase structure of the tungsten copper composite will vaporize and absorb a large amount of heat, so that the temperature of the surface of the throat insert is significantly reduced, so that it can meet the high temperature environment of the rocket.

That is to say, the tungsten copper composite material utilizes the sweating and cooling effect of copper volatilization at a high temperature, which can lower the surface temperature of the tungsten copper and ensure its use under high temperature extreme conditions. Tungsten copper materials can be used not only on the throat of solid rocket motors, but also on missile or rocket engine components such as gas rudders, air rudders, nose cones, guards and fasteners. At the same time, tungsten copper composite materials also used in vacuum switchgear and electronic packaging of its excellent electrical conductivity, thermal conductivity and high temperature resistance.

Do you want to know what is the tungsten copper composite material?

Tungsten copper composites is referred to as "pseudo-alloys", which is the composites of tungsten and copper, it does not solidify or form intermetallic compounds. The weak interaction between tungsten and copper makes them compatible with the advantages of tungsten and copper after compounding. With the properties of high melting point, arc corrosion resistance, fusion resistance and corrosion resistance of tungsten and excellent electrical conductivity of copper. It can be used as a heat dissipating component in large-scale integrated circuits and microwave devices, which can effectively extend the service life of electronic components.

It is not known whether the tungsten copper throat insert will help the Chinese private rockets to rise. Because the material of the solid rocket motor nozzle throat lining is not only include tungsten copper material, also include graphite, SiC ceramic, carbon fiber, phenolic resin, C/C composite and other refractory metals such as tungsten alloy. Finally, the Rockets fans, do you know which one is best suited to "fly" with the missile?

- Tungsten Copper Manufacturer & Supplier, Chinatungsten Online: tungsten-copper.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

Tungsten Hexafluoride Purification Process

- Details

- Category: Tungsten Information

- Published on Tuesday, 16 October 2018 23:22

Tungsten hexafluoride, chemical formula for WF6, is a colorless gas, condensation, light yellow liquid, molar mass 297.83 g/mol, is one of the densest gases. Tungsten hexafluoride is mainly used for chemical vapor deposition of tungsten. It is also used to fabricate interconnects with low resistance and high melting point, large integrated circuit electronic components, protective shields against X-ray or gamma-ray, and high-efficiency solar absorbers.

Narrow Grain Ultra Coarse Tungsten Carbide Powder Preparation

- Details

- Category: Tungsten Information

- Published on Tuesday, 16 October 2018 23:10

As the main raw material of high performance cemented carbide for mining and engineering, the particle size distribution of ultra-coarse tungsten carbide powder has a decisive influence on the quality of cemented carbide. The granularity distribution of tungsten carbide powder is too wide, which will significantly reduce the properties of ultra coarse cemented carbide prepared by using tungsten carbide powder.

sales@chinatungsten.com

sales@chinatungsten.com