Preparation of Tungsten Oxide Nanowires by Hydrothermal Synthesis

- Details

- Category: Tungsten Information

- Published on Sunday, 29 July 2018 23:29

In the existing technology, the synthesis of tungsten oxide nanowires is mainly included in the following methods: high temperature vacuum vapor deposition, surfactant method, or anodic alumina template method. Compared with the above methods, the hydrothermal preparIn the existing technology, the synthesis of tungsten oxide nanowires is mainly included in the following methods: high temperature vacuum vapor deposition, surfactant method, or anodic alumina template method. Compared with the above methods, the hydrothermal preparation process is very simple and most widely used.ation process is very simple and most widely used.

Some scholars have innovated a hydrothermal synthesis method which can effectively solve the problems mentioned above, and can prepare tungsten oxide quantum dots and tungsten oxide nanowires at the same time. The prepared tungsten oxide nanometer is a very good absorbing material. The main process is as follows:

(1) First weighed 0.0667 grams of tungsten hexachloride dissolved in 12 ml of absolute ethanol, stirred to obtain a golden yellow clear tungsten hexachloride ethanol solution;

(2)Transfer the solution prepared in the step (1) to a polytetrafluoroethylene sealed can and put it into a hydrothermal reaction kettle, and heat it in a temperature range of 200 ° C for 10 hours to obtain a hydrothermal a solution comprising tungsten oxide quantum dots, tungsten oxide nanowires, an ethanol reactant and water, wherein the ethanol reactant comprises diethyl ether, ethanol, hydrogen chloride and a small amount of water;

(3)After the natural condition of the solution after the water heat is lowered to room temperature, the polytetrafluoroethylene tank in the hydrothermal reaction kettle is taken out, and the solution in the polytetrafluoroethylene tank is taken out, placed in a centrifuge tube, and centrifuged. The tube was placed symmetrically in a centrifuge and centrifuged at 12,000 rpm for 15 minutes to prepare a solution after centrifugation. After centrifugation, the upper layer of the solution was supernatant, and the supernatant contained tungsten oxide quantum dots, ethanol reactants, and lower layer. For precipitation, precipitation is tungsten oxide nanowires;

(4)The supernatant of the centrifuge solution obtained from the step (3) has been dialysate for 24 hours after dialysis in a dialysis bag with molecular weight of 500, and the pure tungsten oxide quantum dots solution is obtained by dialysis removal of ether, ethanol and hydrogen chloride.

(5)take the precipitate in the step (3) and wash it with deionized water for 6 times, wash away the impurity on the surface, and then freeze and dry the cleaned precipitation at -5 ° C for 24 hours to make the tungsten oxide nanowires.

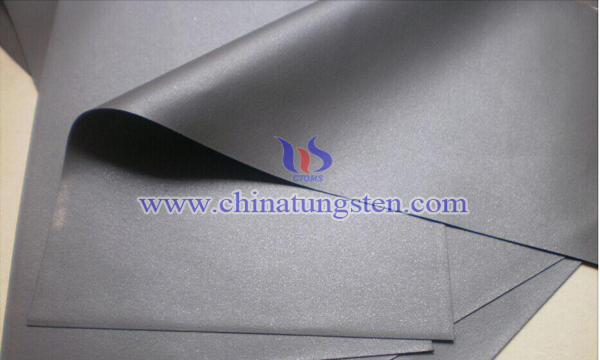

The tungsten oxide nanowires prepared by these methods are very good absorbing materials, which can be applied to the field of electromagnetic shielding and stealth materials, which can improve the compatibility of electromagnetic equipment, strengthen the protection of information technology, and better protect the health of the personnel operating electromagnetic radiation.

- Tungsten Oxide Manufacturer & Supplier, Chinatungsten Online: www.tungsten-oxide.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com