Production Method of Near-Spherical Tungsten Powder

- Details

- Category: Tungsten Information

- Published on Friday, 03 August 2018 19:15

The tungsten powder commonly used in the industry is mainly obtained by reducing tungsten oxide with hydrogen. Such tungsten powder has irregular particle shape, poor fluidity, low bulk density, and it is difficult to obtain a tungsten body with continuous micropores by sintering. In recent years, the demand for near-spherical or spherical tungsten powder has increased day by day, and is widely used in powder metallurgy processes such as porous material preparation, thermal spraying and injection molding.

Some researchers provide a production method for submicron near-spherical tungsten powder, and the production process is as follows:

Accurately weigh 1000g of ammonium paratungstate (APT), placed in a porcelain boat, pyrolyzed at 310 ° C for 1.5h in a muffle furnace to obtain 925g of amorphous ammonium metatungstate (AMT), the weight loss rate is 7.5%; The AMT is dissolved in aqueous ammonia solution, the amount of deionized water and ammonia water is 925ml and 1220ml respectively, stirred for 4h, and allowed to stand for 30min; the supernatant and undissolved materials are vacuum filtered to obtain 2100ml ammonium tungstate solution with a density of 1.255g. /cm3, wherein the effective W content is 525g; in an amount of 5 parts by weight of the effective W content, 23 ml of an aqueous system of low molecular weight polyacrylate (PAANH4, diluted 10 times) is added as a dispersing agent in an ammonium tungstate solution, and stirred for 10 minutes. Uniform; 1100ml concentrated nitric acid was added as a precipitant under strong mechanical stirring, and it was converted into tungstic acid after 5 minutes, stirred for 1 hour, and then allowed to stand for 30 min to obtain sol-like tungstic acid precipitate; the tungstic acid sol was subjected to 2 h. The tungstic acid gel was obtained by vacuum filtration, and placed in a ceramic boat, dried in a muffle furnace at 120 ° C for 12 h; the tungstic acid gel is mechanically broken into small particles of a size not exceeding 10 × 10 × 10 mm, and juxtaposed Pyrolysis at 450 ° C in a muffle furnace in a ceramic boat 2 h, obtaining loose tungsten trioxide; the obtained tungsten trioxide is subjected to ball milling treatment to achieve the purpose of eliminating agglomeration and near spheroidizing treatment, using zirconia grinding balls, the ball to material ratio is 6:1, and the ball milling time is 3 hours; The ball-milled tungsten trioxide powder was placed in a ceramic boat and subjected to ordinary industrial hydrogen reduction at 750 ° C for 5 h in a muffle furnace to obtain a submicron near-spherical tungsten powder.

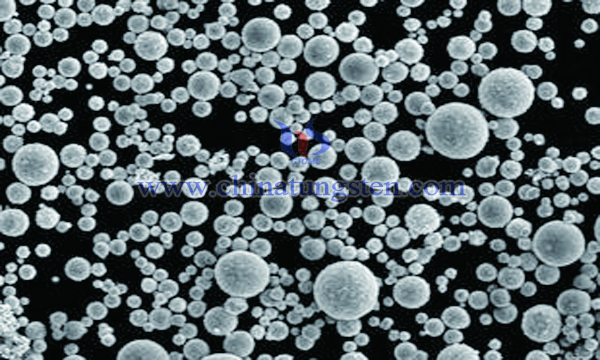

The morphology of the prepared tungsten powder is nearly spherical by field emission scanning electron microscopy (FESEM). The diameter of most particles is between 0.7 and 1 μm. This method can stably prepare submicron near-spherical tungsten powder with simple process, low production cost and large-scale production can be realized.

- Tungsten Powder Manufacturer & Supplier, Chinatungsten Online: tungsten-powder.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com