A Preparation method of Nanometer Ta-W powder for 3D printing

- Details

- Category: Tungsten Information

- Published on Monday, 30 July 2018 18:32

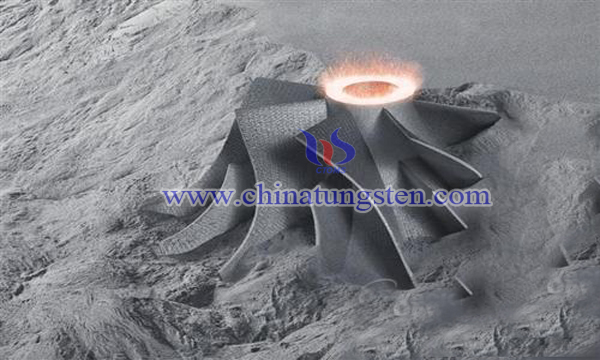

Tantalum-tungsten (Ta-W) alloy is widely used due to its high density, high melting point, high ductility, modulus of elasticity, good processing properties, high temperature strength, high corrosion resistance, weldability and low brittle-to-ductile transition temperature (BDTT). It is used in aerospace, defense, military, chemical, and nuclear industries. With the development of 3D printing technology, Ta-W powder has also become one of the main 3D printing materials, mainly used for printing complex or miniature Ta-W alloys, which also puts higher requirements on the performance of the powder.

This paper describes a nanometer Ta-W powder prepared by nano-in-situ composite technology. The nanometer Ta-W composite powder has high sintering activity, is easy to achieve high densification of materials, reduces internal defects of materials, and significantly improves the mechanical processing properties of materials, and can meet higher requirements for material properties in 3D printing technology. The specific procedures of its production are:

Step 1: Sol-coprecipitation

1) Weight 406g of ammonium paratungstate (APT) into a container containing 30L of fluoroantimonic acid solution, and add 300ml of surfactant polyethylene glycol PEG-600 dropwise, and stir for 30 minutes to obtain a sol solution; the acid solution was measured by tantalum oxide at a concentration of 100 g/L, and an HF concentration of 1.2 mol/L.

2) Add concentrated ammonia water (concentration 9.6N) to the sol solution, add slowly while stirring; until the pH of the solution=9~10, stop adding concentrated ammonia water, and let the pH change after standing for 30 minutes to ensure the change.

3) The precipitate was filtered using a suction filtration apparatus, and the precipitate was sufficiently washed by using a drum ammonia hot water having a concentration of 0.3 mol/L at 75 ° C until the fluorine content in the precipitate is less than 0.5%. Then, the precipitated and filtered powder is placed in a hot air circulating oven and dried at 120 °C for 4 hours. After screening through 100 mesh sieve, a precursor composite powder composed of Ta(OH)5, (NH4)10(H2W12O42)•4H2O phase can be obtained.

Step 2: Hydrogen reduction

The composite powder obtained in the step 1 is heated in a fourteen-tube hydrogen reduction furnace to a temperature of 900 ° C for one hour to obtain a tantalum oxide-tungsten (chemical composition (Ta, O) and W) composite powder;

Step 3: Alkali metal reduction

1) Transfer the tantalum oxide-tungsten composite powder obtained in the step 2 to a reaction vessel (special equipment for stirring sodium reduction), and add alkali metal sodium, calcium chloride, potassium chloride and sodium chloride, and add 1700 g of sodium. 5020 g of calcium chloride, 5020 g of potassium chloride and 5020 g of sodium chloride. After the completion of the feeding, the reaction vessel is evacuated to a vacuum, the degree of vacuum is not more than 26.6 Pa, and then argon gas is introduced as a shielding. Raise the temperature to have a reduction at 920 ° C for 4 hours.

2) When the sodium reducing material is cooled, the material is peeled off from the reaction vessel and being broken into pieces. Then use a pure water to wash away the soluble salt and excess alkali metal, until the conductivity of the solution less than 50 μs/cm. Next, wash with a concentration of 40 % nitric acid for 2 hours, the pickling end point is the solution conductivity <30μs/cm, and then washed with 80 ° C pure water until the solution conductivity is less than 20μs / cm, the obtained powder is placed in a vacuum oven, drying temperature 80 ° C, drying time is After 8 hours, a nanometer Ta-10 wt%W composite powder is obtained.

The powder properties were tested, wherein the grain size was 10 to 200 nm, and the relevant element contents were: W: 9.6%, C: 0.02%, N: 0.065%, O: 2.8%, K: 0.002%, Na: 0.0035%, Ca: 0.002%, Fe: 0.01%, Ni: 0.0018% and the rest content is tantalum.

Step 4: Magnesium reduction deoxidation

Add 110 g of magnesium flakes to the Ta-W composite powder obtained in step 3, mixing them uniformly, putting them into the reaction vessel, first drawing into a vacuum, the vacuum degree is not more than 26.6 Pa, and then heating to 940 ° C by argon gas, and keeping the heat for 2 hours. After cooling to room temperature, the furnace is baked, and then washed with a concentration of 40% nitric acid for 2 hours. The acid pickling end point is a solution conductivity of <30 μs/cm, and then washed with 75 ° C hot pure water until the solution conductivity is <20 μs/cm, and dried for 100 times. The mesh was sieved to obtain an ultrafine (nano) yttrium-tungsten composite powder of Ta-10 wt% W.

The properties of the composite Ta-w alloy powder were examined, wherein the grain size is 10 to 220 nm, and the relevant element contents are: W: 9.5%, C: 0.01%, N: 0.035%, O: 0.28%, K: 0.001%, Na: 0.0015%. Ca: 0.001%, Fe: 0.005%, Ni: 0.0016%, and the rest is tantalum. The composite alloy powder has an average particle size of 2 μm. The powder yield of the entire process is 86%. The performance of Ta-W powder meets the requirement of 3D printing metal material.

- Tungsten Powder Manufacturer & Supplier, Chinatungsten Online: tungsten-powder.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com