Tungsten Alloy Shielding Components

- Details

- Category: Tungsten Information

- Published on Monday, 04 August 2025 16:24

In an era of rapid technological advancement, radiation protection has become a critical issue across various fields. Whether it’s the use of X-rays and gamma rays in medical diagnostics and treatments, the application of radiation in industrial non-destructive testing, or the development and utilization of nuclear energy in the nuclear industry, radiation has brought significant convenience to humanity while posing potential threats to human health and environmental safety. As a "stalwart guardian" in radiation protection, tungsten alloy shielding components are gradually entering the public eye, playing an increasingly vital role.

Tungsten alloy shielding components are devices specifically designed to block or attenuate the spread of radiation. Their core material is an alloy composed of tungsten as the base, combined with small amounts of metal binders such as nickel, iron, or cobalt. Tungsten, a rare metal, possesses remarkable properties. With a density as high as 19.3 g/cm³, this high-density characteristic is a key factor in the efficient radiation shielding capability of tungsten alloy shielding components. When radiation particles encounter tungsten alloy shielding components, the densely packed tungsten atoms act like a formidable barrier, effectively blocking the particles and reducing radiation intensity.

From a microscopic perspective, radiation particles possess high energy and penetration capabilities. When they strike tungsten alloy shielding components, they undergo a series of complex interactions with tungsten atoms, including the photoelectric effect, Compton scattering, and pair production. In the photoelectric effect, radiation photons transfer energy to electrons within tungsten atoms, causing the electrons to break free and become photoelectrons. Compton scattering involves a photon colliding with an electron, transferring part of its energy to the electron and scattering in a different direction. Pair production occurs when a photon with sufficiently high energy interacts with a tungsten atom to produce a pair of positive and negative electrons. These interaction processes continuously absorb and dissipate the energy of radiation particles, preventing them from penetrating the shielding component and continuing to propagate, thus achieving the goal of radiation shielding.

I. Unveiling the Performance of Tungsten Alloy Shielding Components

One of the most notable characteristics of tungsten alloys is their high density, typically ranging from 16.5 to 18.75 g/cm³. This density value far exceeds that of common shielding materials, such as steel at approximately 7.8 g/cm³ and lead at 11.34 g/cm³. In the field of shielding, a material’s density is closely related to its shielding effectiveness: generally, the higher the density, the stronger the shielding capability. For example, under the same shielding conditions, the thickness of lead required to achieve the same radiation shielding effect would be greater than that of tungsten alloy. This is because high density means a greater number of atoms per unit volume, increasing the probability of interactions with radiation particles and thus more effectively blocking and attenuating radiation.

Tungsten alloys demonstrate strong shielding capabilities against various types of radiation. Take common X-rays and gamma rays, for instance: X-rays, as high-frequency electromagnetic waves, are widely used in medical imaging (e.g., X-ray machines and CT scans) and radiotherapy, while gamma rays, common high-energy electromagnetic radiation in nuclear medicine and radiotherapy, possess high energy and strong penetration. Thanks to their high density and atomic number, tungsten alloys engage in rich interaction mechanisms with radiation particles. In radiotherapy equipment within the medical field, the application of tungsten alloy shielding components effectively ensures that medical personnel and patients are protected from unnecessary radiation exposure, providing a solid guarantee for medical safety.

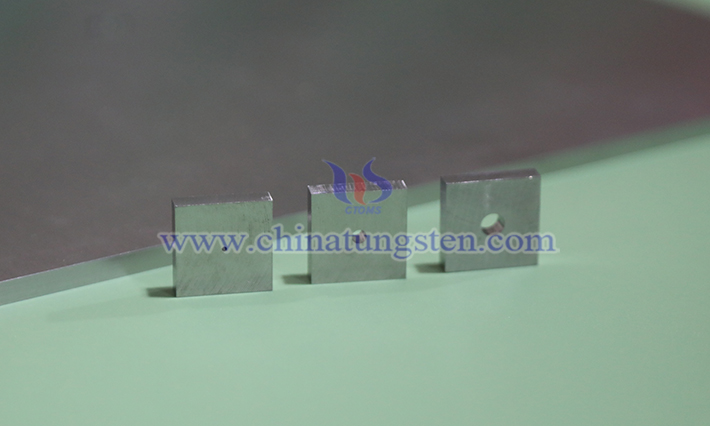

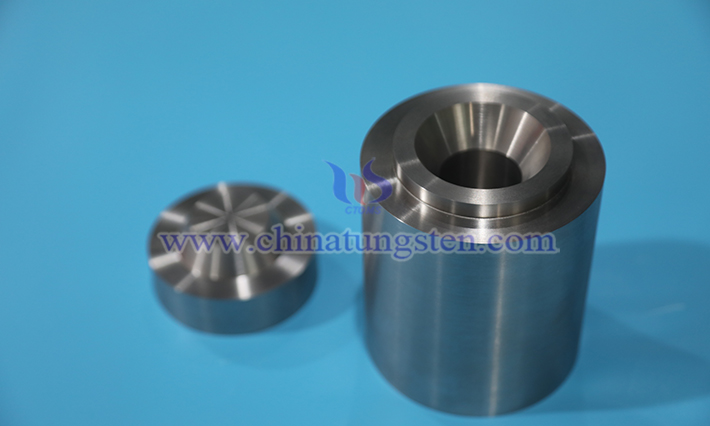

In practical applications, the ability to process materials into various shapes and specifications based on different scenarios and needs is highly important, and tungsten alloys excel in this regard. Through advanced processing techniques, tungsten alloys can be crafted into complex shapes such as collimators, shielding cans, and shielding rings. The powder metallurgy forming process allows for the control of tungsten alloy composition and density, producing high-performance shielding components. 3D printing technology enables personalized customization, allowing for the rapid manufacturing of shielding components with special structures and shapes to meet the demands of specific fields.

Whether in high-temperature, high-pressure environments or in the presence of acid-base chemical corrosion, tungsten alloy shielding components maintain relatively stable performance. In high-temperature settings, tungsten alloys’ high melting point enables them to withstand elevated temperatures without deforming or degrading in performance. In high-pressure environments, their high strength and hardness allow them to resist pressure effectively. In terms of chemical stability, tungsten alloys exhibit good corrosion resistance to most acids and bases, resisting chemical erosion and ensuring the reliability of shielding components during long-term use.

II. Application Scenarios of Tungsten Alloy Shielding Components

In the medical field, the application of radiation technology has revolutionized disease diagnosis and treatment but has also introduced challenges in radiation protection. In radiotherapy equipment such as medical linear accelerators, tungsten alloys are widely used to manufacture shielding components like collimators and multi-leaf collimators. Collimators align the beams of radiation emitted from the source, directing them toward the tumor site while minimizing radiation damage to surrounding healthy tissues. Thanks to their excellent high density and radiation shielding capabilities, tungsten alloys effectively block and scatter radiation. Multi-leaf collimators, composed of multiple independently movable tungsten alloy leaves, can adjust the irradiation range in real-time based on the tumor’s shape and size, further improving the precision and effectiveness of radiotherapy. In medical imaging equipment such as CT scanners and X-ray machines, tungsten alloy shielding components are equally important. To protect patients and operators from unnecessary radiation, tungsten alloy shielding sleeves are typically installed around the X-ray tubes of CT scanners, effectively preventing X-ray leakage.

In the industrial sector, during geological drilling to detect oil and gas resources, radioactive sources are often used to emit radiation. Tungsten alloys, with their high density and excellent shielding performance, are employed to create containers for shielding radioactive sources and gamma ray collimators. These collimators guide rays to target areas, and by analyzing the signals returned after the rays interact with subsurface materials, the presence of oil and gas resources can be determined. In industrial radiography, tungsten alloy X-ray flaw detection machines operate on the principle of X-rays penetrating materials and attenuating within them to identify internal defects, a non-destructive testing method. X-rays can detect internal flaws in both metal and non-metal materials and their products, such as pores or slag inclusions in welds.

In the nuclear industry, the handling of nuclear waste poses a significant challenge, as it contains large amounts of radioactive materials that, if not properly managed, could pose long-term threats to the environment and human health. Tungsten alloy shielding cans, with their high density, high strength, corrosion resistance, and environmentally friendly, non-toxic properties, have become an ideal choice for storing and transporting nuclear waste. They effectively shield radiation emitted by nuclear waste, preventing the leakage of radioactive materials. During the transportation of nuclear waste, tungsten alloy shielding cans can withstand certain levels of impact and vibration, ensuring safe transport.

- Chinatungsten Online: www.tungsten-alloy.com

- CTIA GROUP LTD: en.ctia.group

- Tungsten News & Price: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com