Unsung Heroes in Medicine: Tungsten Alloy Shielding Components

- Details

- Category: Tungsten Information

- Published on Monday, 04 August 2025 16:16

In the context of continuous advancements in modern medical technology, a variety of sophisticated diagnostic and treatment methods have brought hope to patients. However, while these technologies play a crucial role, they also introduce unavoidable radiation risks. Take radiotherapy, for example, which is a key method in cancer treatment, utilizing high-energy rays to destroy cancer cells. During this process, while the rays target cancer cells, they also affect surrounding healthy tissues. Radiotherapy can lead to radiation dermatitis, causing skin redness, itching, peeling, or even ulceration in patients; it may also result in radiation pneumonitis, leading to symptoms such as coughing, shortness of breath, and difficulty breathing. Beyond the physical harm to patients, radiotherapy may pose long-term health risks, including an increased likelihood of second primary tumors, undoubtedly making the road to recovery more challenging. Similarly, CT scans, a commonly used medical imaging method, enable doctors to clearly observe internal human structures and play a vital role in disease diagnosis. However, the X-rays used in CT scans, being ionizing radiation, can impact human cells.

In medicine, these radiation risks settings not only threaten patient health but also pose potential hazards to the working environment of medical personnel. Effectively addressing radiation issues has become an urgent challenge in the medical field. In this context, tungsten alloy shielding components have gradually come into the spotlight, offering new hope for solving radiation-related problems.

I. Understanding Tungsten Alloy Shielding Components

Before exploring how tungsten alloy shielding components mitigate radiation issues in medical settings, let’s first understand what they are. As the name suggests, tungsten alloy shielding components are alloy products made by smelting tungsten as the primary component with other metal elements, such as nickel and iron, through specific processes.

Tungsten, a remarkable metal, boasts a series of outstanding properties. Its density reaches 19.35 g/cm³, ranking among the highest among common metals; its melting point is 3,410°C, allowing it to maintain stable form without melting or deforming under high temperatures. Moreover, tungsten has considerable hardness, with a Mohs hardness of up to 7.5, indicating strong wear resistance and the ability to maintain good performance under various complex conditions.

When tungsten forms an alloy with other metal elements, these properties are further optimized and enhanced. Alloying not only improves the material’s comprehensive mechanical properties, making it easier to process and shape, but also endows tungsten alloy shielding components with excellent radiation shielding capabilities.

So, how do tungsten alloy shielding components achieve their radiation shielding ability? This is primarily based on their high density and high atomic number. In the field of radiation protection, a key principle states that a material’s ability to attenuate radiation is closely related to its density and atomic number. The high density of tungsten alloys increases the likelihood of radiation particles interacting with atoms as they pass through, raising the probability of collisions. The high atomic number enhances the occurrence of processes such as the photoelectric effect, Compton scattering, and pair production, which effectively absorb and scatter radiation energy, thereby achieving the purpose of shielding radiation.

II. perse Applications of Tungsten Alloy Shielding Components

Key Role in Radiotherapy Equipment

In the field of radiotherapy, linear accelerators and gamma knives are common devices that utilize high-energy rays to target tumors, bringing hope to numerous cancer patients. In these devices, tungsten alloy shielding components play a critical role.

Linear accelerators accelerate electron beams to strike a target material, generating high-energy X-rays or outputting high-energy electron beams for tumor treatment. Precise control of the rays is essential in this process. Tungsten alloy collimators act like precise “ray guides,” directing the rays steadily in a specified direction and preventing chaotic scattering. After the rays are generated by the accelerator, the tungsten alloy collimator adjusts their direction and range, ensuring they irradiate the tumor site in a specific shape and angle. For instance, for irregularly shaped tumors, the collimator can adjust the ray shape to match the tumor’s contour, maximizing the radiation dose to the tumor while minimizing damage to surrounding healthy tissues.

The gamma knife, on the other hand, uses gamma rays produced by radioactive nuclides like cobalt-60 for treatment, focusing multiple gamma ray sources on the tumor target to deliver a high radiation dose. In the gamma knife, tungsten alloy shielding rings play a crucial shielding role. Surrounding the ray sources, these rings effectively block rays from scattering in unnecessary directions. This not only protects equipment operators and the surrounding environment from radiation hazards but also ensures that gamma rays are more concentrated on the tumor, enhancing treatment efficacy.

Guardian of Protection in Medical Imaging Equipment

In medical imaging, CT machines and X-ray devices are commonly used tools that help doctors obtain images of internal human structures, providing critical insights for disease diagnosis. However, these devices generate X-rays during operation, posing potential threats to the health of patients and medical personnel. Tungsten alloy shielding components serve as loyal “guardians of protection,” silently safeguarding everyone’s safety.

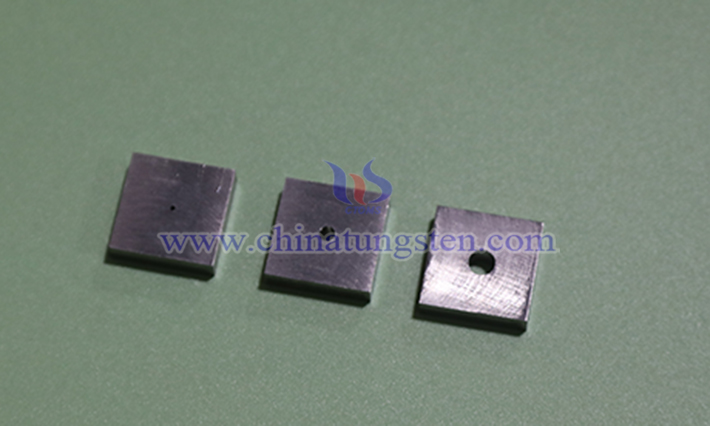

CT machines use X-rays for cross-sectional scanning of the body to obtain detailed internal images. In CT machines, tungsten alloy shielding components have wide applications. In the detector section, tungsten alloy sheets offer excellent stability and resistance to deformation, serving as important anti-scatter components. Over prolonged use, these sheets are less prone to deformation, preventing signal distortion caused by changes in channel width as X-rays pass through. Additionally, tungsten alloy sheets provide effective radiation shielding, blocking scattered X-rays and reducing radiation exposure to patients and medical personnel.

- Chinatungsten Online: www.tungsten-alloy.com

- CTIA GROUP LTD: en.ctia.group

- Tungsten News & Price: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com