How to Refine Low Grade Tungsten Ore and Tungsten Slag

- Details

- Category: Tungsten Information

- Published on Monday, 30 July 2018 19:50

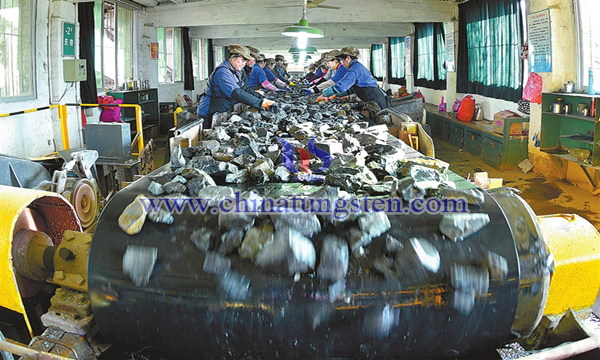

The advantage of tungsten resources in China is gradually disappearing, the resource crisis is prominent. At present, with tungsten resources becoming more and more complex and difficult to choose, all kinds of high impurity and low grade tungsten ore raw materials will become the main body of raw material treatment for tungsten smelting enterprises in the future. In addition, as China encourages the development of recycling economy, the recovery and utilization of various tungsten smelting residues will also receive more and more attention from enterprises.

The extraction of tungsten from low grade tungsten concentrate and tungsten slag is of great significance for prolonging the useful life of tungsten resources in China and reducing the emission of wastes. However, because the process of smelting changes the physical structure of minerals or the chemical forms of some components, it is difficult for tungsten slag to be recovered by ore dressing methods. Therefore, a new effective new method for the comprehensive utilization of tungsten resources including low grade tungsten concentrate and tungsten slag has been developed to make environmental benefits, economic and social benefits. Unification is of great practical significance to the development of China's tungsten Industry and the development of national economy.

Some scholars have provided a simple process, economical and practical, and can effectively realize the efficient enrichment and selective separation of low grade tungsten concentrate, tungsten slag and other valuable elements. This method effectively improves the comprehensive utilization efficiency of low grade tungsten concentrate, tungsten slag and other resources.

After mixing low grade tungsten concentrate or tungsten slag and pulverized coal by mass ratio of 3 to 5:1, then adding tungsten lignite concentrate and the reduction roasting agent of 10 to 20% of the total quality of pulverized coal, the products were reduced to 30 ~ 60min by reduction and roasted in the environment of 800~900°C, the products obtained by reduction roasting were neutral leaching after grinding and obtained tungstate solution and leaching residue. The leaching slag is separated by magnetic field and separated by magnetic separation to obtain refined iron and valuable metal tailings.

Tungsten slag containing iron 41wt% and tungsten 1.8wt% is treated. The quantity of tungsten slag and pulverized coal is mixed with the mass ratio of 4:1. The amount of sodium sulfite of reducing roasting agent is 20% of tungsten slag and pulverized coal, the calcination temperature is 900°C, the calcination time is 30min. The roasted products are grinded to 70% by grinding machine to -0.074mm particles, the neutral leaching is carried out according to the ratio of solid liquid to 1: 5, the leaching temperature is carried out. The leaching time is 15min, the liquid is tungstate solution is obtained. The leaching residue is separated by magnetic separation in the 500GS magnetic field. The concentrate is iron concentrate, and the tailings are mixed with valuable elements such as manganese, copper, zinc, bismuth, cobalt, tantalum, niobium and so on. The magnetite tailings are desilication by dilute hydrochloric acid (the concentration of dilute hydrochloric acid is 8%, the leaching time is 15min), the concentration of concentrated hydrochloric acid is extracted by the concentrated hydrochloric acid (25%, the leaching time is 15min, the concentration of hydrochloric acid is 1.2 times of the theoretical molar amount), and the enrichment of tantalum and niobium, the leaching of tantalum and niobium (HF acid) by hydrofluoric acid (HCl) The concentration is 40%, the amount of HF acid is 1.2 times the theoretical molar content, the leaching time is 2h, and leaching temperature is 70°C, which means that the tantalum and niobium rich leaching solution is obtained.

- Tungsten Manufacturer & Supplier, Chinatungsten Online: www.chinatungsten.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com