A New Method for the Coarse Grain Tungsten Carbide Manufacturing

- Details

- Category: Tungsten Information

- Published on Monday, 30 July 2018 20:12

The coarse grain tungsten carbide has a series of advantages, such as good crystallizability, less structural defects and large subcrystal size. It is used in the production of hard alloys. The mining tools, stamping dies, drilling and mining tools can also be applied to hard surface materials such as spray and spray welding.

The key to preparation of high performance coarse-grained cemented carbide is the preparation of high quality tungsten powder with coarse grain, good uniformity, good crystallization and high purity.

A more widely used method for preparing coarse grained tungsten carbide powder abroad is thermite method. This method is made of tungsten concentrates, iron oxide as oxidant, aluminum as reducing agent and calcium carbide as carbonization agent. The coarse grain tungsten carbide powders are prepared by mixing these materials at over 2000°C and melting and carbonizing. In practice, it is found that the grain size of coarse grain tungsten carbide prepared by aluminum heat method is very coarse, but the main disadvantages is that the process is longer, some impurities can not be completely removed, and ultimately affect the comprehensive properties of the alloy.

In view of the shortage of thermite method, a new method of preparing uniform coarse grain tungsten powder has been created by domestic researchers. The tungsten oxide powder or the mixture of tungsten oxide powder and tungsten powder is used as the raw material in the reduction furnace. The coarse grain tungsten powder obtained by reduction is screened out to remove the oxide skin, the coarse grain tungsten is obtained. When the powder is reduced, a certain flow of water vapor and hydrogen is sent to the reduction furnace first. The partial pressure ratio of water vapor and hydrogen to the reduction furnace is 0.1 ~ 1.64 PH2O/PH2, then pushed into the material boat containing the powder material, the grain size of the coarse grain tungsten powder obtained by the reduction is 10~100 μm. The examples are as follows:

The blue tungsten oxide powder with a Fsss particle size of about 20μm is used as raw material, about 6Kg raw material per boat is used. The temperature of the reduction furnace is raised to 1000°C, steam and hydrogen are fed into the furnace, the PH2O/PH2 of the furnace is controlled to be 0.45. Then it is pushed into the canoe to reduce about 15h, the coarse grain tungsten powder is obtained by screening the oxide skin after the material is screened. The grain size of Fsss is about 21 μm, the grain of tungsten powder is very coarse, the particle crystal is good.

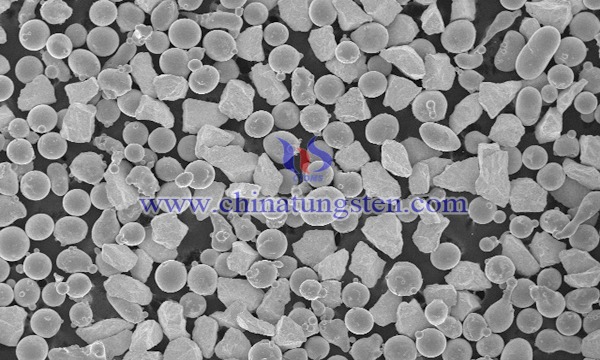

The coarse grain tungsten powder is mixed with carbon and carbon distribution is 6.15%, then carbonized in the carbonization furnace, the carbonization temperature is 2300°C, the carbonization time is about 2h, the carbonization atmosphere is hydrogen. When the furnace temperature drops to the outlet temperature, the coarse grain tungsten carbide lump is crushed by 1 to 1 ball material and then coarse-grained tungsten carbide powder is obtained after sieving. The grain size of coarse grain WC powder is about 23.2 μm, the surface of WC powder is dense, smooth and crystalline.

The coarse grain tungsten carbide powder prepared by high temperature carbonization of coarse grain tungsten powder and carbon black prepared by this method also has a series of advantages such as coarse grain, high purity, good crystallinity, less structural defects, large subgrain size, high microhardness and small microstrain. The coarse grain and ultra coarse grained cemented carbide prepared by the coarse grain tungsten carbide powder has significantly improved comprehensive properties.

- Tungsten Carbide Manufacturer & Supplier, Chinatungsten Online: tungsten-carbide.com.cn

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com