A Preparation Method of Ultrafine Grain Tungsten-Copper Alloy

- Details

- Category: Tungsten Information

- Published on Wednesday, 01 August 2018 17:30

Pure tungsten and tungsten-based high specific gravity alloy materials have the advantages of high melting point, high density, high strength, high hardness and high wear resistance. In addition, it has small thermal expansion coefficient, good corrosion resistance and oxidation resistance, and good electrical and thermal conductivity. Therefore, it has been widely used in semiconductor industry, defense industry and aerospace. It is used as a counterweight and shock absorbing material on aircraft; it is used as armor-piercing projectiles and submunitions in military industry; it is used as an anti-X-ray shielding material in the medical industry; it is used as a high-specific gravity alloy on Vibrator electrode material of mobile phones, etc.

Tungsten-copper composite is a two-phase pseudoalloy composed mainly of W and Cu. It has excellent thermal conductivity and designable expansion coefficient. It is used as a heat sink substrate for microelectronic packages such as CPU, IC, and solid-state microwave tube. It has good matching sealing with semiconductor silicon, gallium arsenide, aluminum oxide and antimony oxide can be achieved to support and dissipate heat. In addition, tungsten-copper composite materials have good arc erosion resistance, fusion resistance, high strength and high hardness, and are widely used as electrical contact materials, electric resistance welding, electric discharge machining and plasma electrode materials.

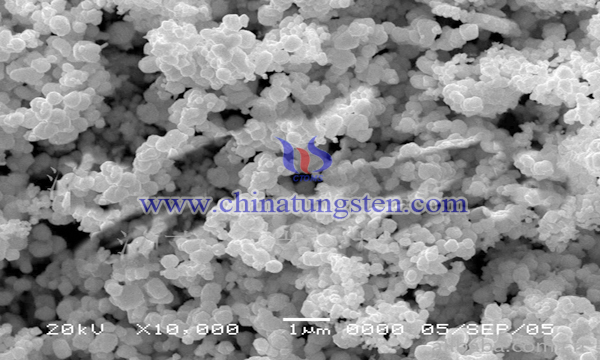

In summary, with the expansion of the application field, higher requirements are placed on the quality and performance of tungsten-based materials, including high density, high structural uniformity, and high thermal and electrical properties. In order to achieve high mechanical properties, the use of ultra-fine and microcrystalline refractory tungsten alloy materials has increasingly become the development trend of refractory tungsten-based alloys and composite materials. However, since ultrafine crystal grains (especially nano-sized crystal grains) have high activity and rapidly grow in sintering, it is difficult to obtain an ultra-fine crystal material without control.

It can be seen that the performance of tungsten-copper alloy, in the final analysis, is how to control the crystal growth of ultra-fine tungsten powder. In order to achieve this goal, some scholars have proposed a tungsten-copper alloy with controllable grain size (such as Ni-Cu, W-Ti-Cu). By strengthening the sintering of ultra-fine grain tungsten powder of a tungsten-copper alloy and shortening the sintering time of tungsten-copper alloy, the grain growth phenomenon which may occur during the sintering process is avoided, and the main processes are as follows:

a. Preparation of raw materials:

Tungsten powder with particle size <10μm is selected. When the particle size of tungsten powder is less than 1μm, it needs to be granulated in advance to improve its molding properties. For t tungsten-copper alloy, tungsten powder and alloying elements are needed. Add 0.1% to 5% by weight, and then have a mechanical mixing; the alloying elements are one or two of Cu, Ni, Zr, Ti; for tungsten-copper composites, tungsten powder and copper powder are required (10% to 90% by volume, for mechanical mixing;

b. The molding of the raw embryo:

The mixed powder is molded, with the molding pressure is 30--100 MPa, or have a cold isostatic pressing with pressure 100-300 MPa;

c. Sintering of the raw embryo:

The raw embryo is placed in a pyrophyllite mold and placed in a press; firstly, a pressure of 1-10 GPa is applied to the sample, and the pressure is two-way pressure or six-sided pressure; then the sample is applied 10-25 kW of alternating current is applied to both ends for sintering. The energization time is 30 seconds to 3 minutes. After electrification and sintering, the pressure is maintained for 0.5-3 minutes. The sintered body is grounded and polished, the relative density of 96-99%.

The process uses a method of energization and sintering under ultra-high pressure to prepare a tungsten-copper alloy with controlled grain size, and applies ultra-high pressure to strengthen the sintering of the tungsten-copper alloy and shorten the sintering time of the tungsten-copper alloy, thereby avoiding Grain growth that may occur during sintering. The application of high alternating current causes the tungsten body to be heated by its own resistance to obtain the desired sintering temperature. In the tungsten-copper alloy, copper does not undergo significant melt loss during the sintering process, and the original composition content can be maintained. The prepared ultrafine grain tungsten-copper alloy has a good mechanical properties and thermal shock resistance, and are suitable for electronic packaging materials, thermal deposition materials, electrical contact materials and high temperature plasma scouring components.

- Tungsten Alloy Manufacturer & Supplier, Chinatungsten Online: www.tungsten-alloy.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com