Tungsten Copper Gradient Materials Preparation by Thermochemical Method

- Details

- Category: Tungsten Information

- Published on Tuesday, 03 July 2018 10:56

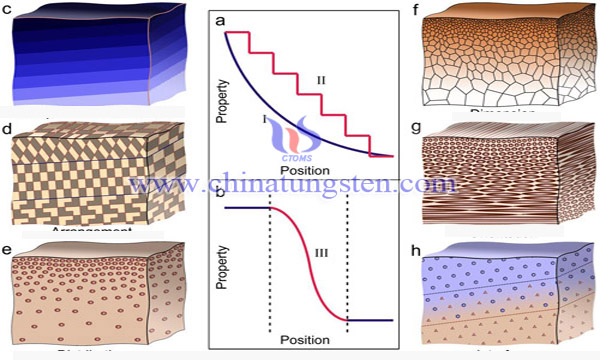

Tungsten copper alloy is a pseudo alloy consisting of insoluble tungsten and copper. The alloy has the advantages of high melting point, corrosion resistance, low expansion coefficient, wear resistance and so on. At the same time, it has the advantages of high conductivity and thermal conductivity, good plasticity and easy processing of copper, but in many cases, it is required to tolerate high temperature on one side of the material. The other side is connected to the copper or copper alloy with good thermal conductivity. Because the physical properties of tungsten and copper are quite different, the single component tungsten copper alloy is difficult to relieve the thermal stress inside and on the interface, and the functionally graded material can solve this problem better.

One side of the FGM is highly conductive copper, and the other side is low expansion, high melting point, high hardness tungsten, the middle is a transition layer with gradient change. This nonuniform composite material can integrate various properties of materials and have the function of thermal stress release. It can give full play to the intrinsic characteristics of tungsten and copper. It has good mechanical properties, ablative resistance, thermal shock resistance and so on. It is very suitable to be used as a super high piezoelectric contact material and high power electronic package. Devices used in high-tech fields such as heat sink, nozzle throat liner, electron beam target, and plasma oriented divertor materials in nuclear fusion devices.

The preparation technology of tungsten copper gradient materials is mainly infiltration process, plasma spraying and thermochemical process. The technology of infiltration and plasma is a common method, but manufacturing tungsten copper gradient materials is more troublesome. Therefore, this paper focuses on thermochemical method.

Three layers of tungsten copper gradient materials were prepared by powder compaction:

(1) Ammonium para tungstate, copper nitrate and water were divided into 3 kinds of solutions according to the mass ratio of 16:5:21, 10:13:23 and 1:4:5 respectively. After stirring for 30 minutes, a transparent sol system was formed. The above sol was spray drying at 140°C, 3 kinds of tungsten copper composite precursor powder with different tungsten copper ratios were obtained.

(2) Three kinds of tungsten copper composite precursor powder is calcined in the air. The calcining temperature is 600°C and the calcining time is 120 minutes, the corresponding three kinds of oxide composite powder are obtained.

(3) Three kinds of oxide composite powders were reduced in H2 and the reduction temperature was 700°C. The ultrafine tungsten copper composite powder W10Cu (Cu content 10%), W32Cu (Cu content 32%) and W60Cu (Cu content 60%) were obtained respectively.

(4) According to the thickness of each layer designed by functionally graded materials, the corresponding W10Cu, W32Cu and W60Cu ultrafine tungsten copper composite powders were loaded into the isostatic pressing die and pressed into the blank under 150MPa.

(5) The sintered blank is sintered in H2, the sintering temperature is 1380°C and the sintering time is 2 hours. The 3 layer structure of tungsten copper functionally gradient material is obtained, the transition between each layer is natural, there is no defect.

The tungsten copper gradient material with thermochemical method is formed by one sintering process, the process is simple, no organic binder or pore making agent is added, and no copper permeation step is needed, it is suitable for mass production of large size tungsten copper functionally graded material components.

- Tungsten Manufacturer & Supplier, Chinatungsten Online: www.chinatungsten.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com