Process of Liquid Phase Sintering

- Details

- Category: Tungsten Information

- Published on Friday, 02 March 2018 21:37

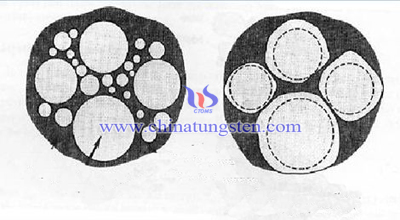

Quantity of Sintering Liquid Phase

- Details

- Category: Tungsten Information

- Published on Friday, 02 March 2018 21:31

Sintering: Solubility of Solid Phase

- Details

- Category: Tungsten Information

- Published on Friday, 02 March 2018 21:27

Rare Earth Doped Ultrafine Tungsten Wire Preparation Process

- Details

- Category: Tungsten Information

- Published on Friday, 02 March 2018 21:24

Adding a certain amount of rare earth elements into tungsten can change the performance of tungsten wire, such as adding cerium or thorium into tungsten can improve the electron emission and ablative ability, and improve the processability of tungsten at the same time. The tungsten alloy wires and products produced by these properties are mainly used in electronic tube hot wire, argon arc welding electrode, pulse tube heating wire and so on.

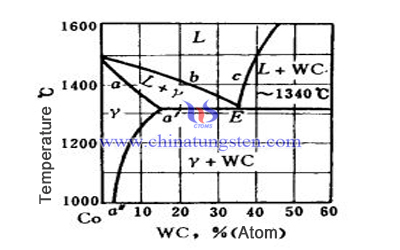

Composition Changes of WC-Co Tungsten Carbide

- Details

- Category: Tungsten Information

- Published on Friday, 02 March 2018 21:21

Manufacturing Strategy of Tungsten Shield

- Details

- Category: Tungsten Information

- Published on Friday, 02 March 2018 21:06

Tungsten atomic number of 74, a density of 19.35g / cm3, has good radiation shielding properties, and does not produce secondary electron radiation, is used to make nuclear radiation shielding material ideal. But it is worth noting that tungsten is a refractory metal with high melting point and poor toughness and toughness. It is difficult to form and process and has high cost, so it is difficult to prepare applied parts with more complex shape. Therefore, it is subject to many limitations when applied.

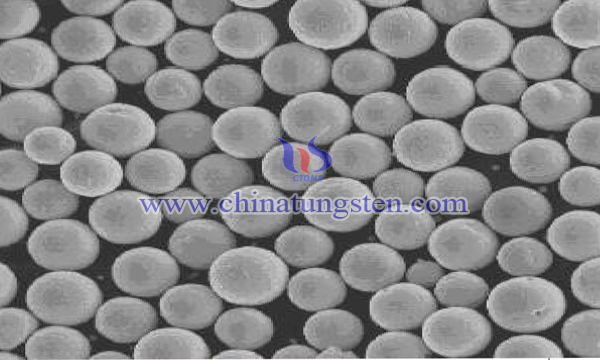

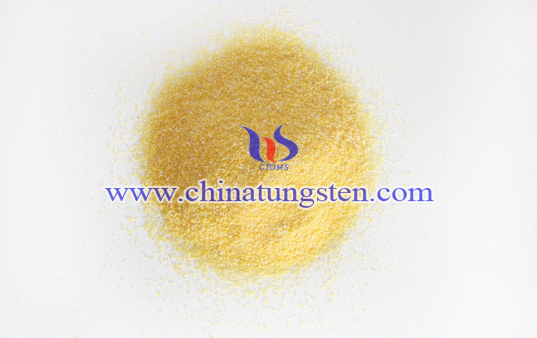

A New Improvement Scheme for Spherical Tungsten Carbide Powder

- Details

- Category: Tungsten Information

- Published on Friday, 02 March 2018 20:43

The preparation methods of spherical tungsten powder are various. The domestic production method is mainly focused on the improvement of traditional production technology, so as to get the tungsten carbide powder with regular shape and fine structure. Recently, a kind of improved method of spherical tungsten powder has been put forward by some scholars.

Preparation of Spherical Tungsten Carbide in Foreign Countries

- Details

- Category: Tungsten Information

- Published on Friday, 02 March 2018 19:57

Spherical tungsten carbide powder is an important thermal spraying material. It is playing a more and more important role in electronic information, metallurgy, machinery and other industries. Compared with the ordinary multi angle tungsten carbide powder, the spherical tungsten carbide powder has many differences.

Pd / WO3 Catalyst

- Details

- Category: Tungsten Information

- Published on Friday, 02 March 2018 09:56

The defect tungsten oxide has a certain reduction ability, and the two reactants are directly synthesized by in-situ method at room temperature to synthesize Pd / WO3 composite material. This kind of mild, simple and easy synthesis method, obtained Pd nanoparticles smaller particle size, and evenly distributed in the tungsten oxide nanowires surface.

Styrene Catalytic Defects Tungsten Oxide

- Details

- Category: Tungsten Information

- Published on Friday, 02 March 2018 09:33

The composite catalyst styrene can catalyze the defective tungsten oxide, in which the mass proportion of Pd element is 3%. Internal standard method can be used to test the percentage of the product, 1,3,5-trimethylbenzene as an internal standard, the correction factor of 0.8451.

sales@chinatungsten.com

sales@chinatungsten.com