Polypyrrole Coated Defect Tungsten Oxide

- Details

- Category: Tungsten Information

- Published on Friday, 02 March 2018 09:26

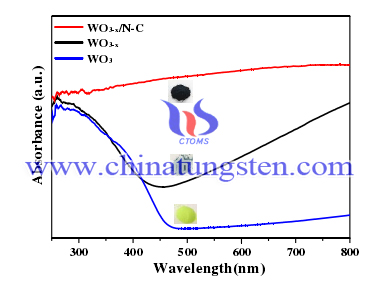

Polypyrrole-coated defect tungsten oxide composites were prepared by chemical polymerization, and then the defect tungsten oxide composite, nitrogen-carbon doped tungsten oxide, was obtained by calcination at high temperature. The synthesis of these two parts is as follows:

Tungsten Oxide Electrode Electrochemical Properties

- Details

- Category: Tungsten Information

- Published on Friday, 02 March 2018 09:18

To study the electrochemical performance of the tungsten oxide electrode material, the charge-discharge curve of the tungsten oxide electrode material at a constant current density of 100 mA was tested at room temperature. The test voltage range was 0.005-3.0 V. In the first cycle of charge and discharge process, the tungsten oxide electrode discharge capacity of 1811mA, charge capacity of 1168 mA, Coulomb efficiency of 64.5%.

Tungsten Oxide Composite Electrode

- Details

- Category: Tungsten Information

- Published on Friday, 02 March 2018 08:57

The discharge rate performance of the two electrode materials of tungsten oxide composite electrode and tungsten oxide electrode can be obtained by subjecting the material to multiple charge-discharge cycles with different current densities. Tungsten oxide composite electrodes have reversible capacities of 1004, 795, 578, 400 and 243 mA at current densities of 100, 200, 500, 1000 and 2000 mA, respectively.

Citric Acid Affects Tungsten Oxide

- Details

- Category: Tungsten Information

- Published on Thursday, 01 March 2018 11:18

In the synthesis of tungsten oxide, ammonium tungstate may be added as the tungsten source. The addition of citric acid can effectively control the morphology of tungsten oxide. Hydrothermal synthesis of tungsten oxide by adding tartaric acid and citric acid and other organic acids can affect the tungsten oxide nanomaterials relative growth rate of different crystal planes to effectively control the tungsten oxide crystal growth and morphology.

Palladium / Tungsten Oxide Composite XPS Spectra

- Details

- Category: Tungsten Information

- Published on Thursday, 01 March 2018 11:11

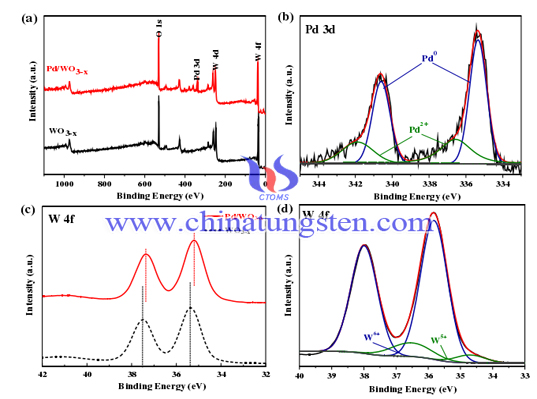

The elemental valence state and composition of the prepared palladium / tungsten oxide composite can be measured by XPS spectroscopy. The XPS score of the palladium / tungsten oxide composite clearly shows that the resulting composite contains tungsten, oxygen and palladium, demonstrating the successful synthesis of the palladium / tungsten oxide composite.

Palladium-Modified Tungsten Oxide Process

- Details

- Category: Tungsten Information

- Published on Thursday, 01 March 2018 11:10

Palladium is a silver-white transition metal, softer, with good ductility and plasticity, forging, rolling and drawing. Bulk metal palladium can absorb a large amount of hydrogen, the volume significantly expanded, brittle and even broken into pieces. The use of palladium-modified tungsten oxide in the structure will have more oxygen defects, help to improve its surface chemical activity.

Tungsten Oxide Raman Spectrum

- Details

- Category: Tungsten Information

- Published on Thursday, 01 March 2018 11:07

Raman spectrum is a scattering spectrum. Raman spectroscopy is based on the Raman scattering effect discovered by Indian scientist Raman. The scattering spectra with different incident light frequencies are analyzed to obtain molecular vibration and rotation information and applied to the analysis of molecular structure.

Tungsten Oxide Nanomaterial XPS Spectrum

- Details

- Category: Tungsten Information

- Published on Thursday, 01 March 2018 11:04

To investigate the non-stoichiometric characteristics of tungsten oxide nanomaterial, XPS spectra can be used to determine valence information of each element in the obtained tungsten oxide nanomaterials and their surface compositions. The XPS spectrum clearly shows that the tungsten oxide nanopowders have both tungsten and oxygen elements and do not contain other impurity elements.

Improvement of Ultra Coarse Tungsten Carbide Powder

- Details

- Category: Tungsten Information

- Published on Wednesday, 28 February 2018 21:00

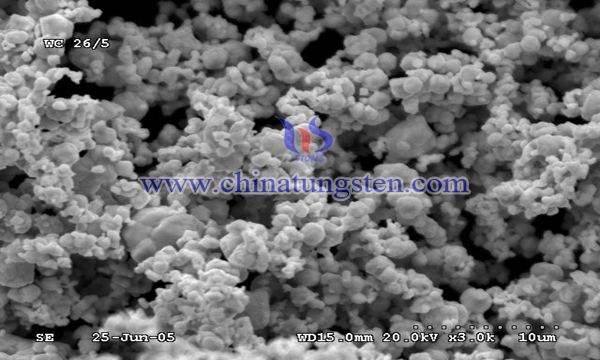

Because of ultra coarse tungsten based alloys have good strength and toughness etc, so more and more widely used in the field of petroleum drilling, mining tools, stamping die, hard material etc.. The production of ultra coarse tungsten based cemented carbide needs high quality raw material of ultra coarse tungsten carbide powder.

Preparation of High Quality Submicron Tungsten Powder

- Details

- Category: Tungsten Information

- Published on Wednesday, 28 February 2018 20:04

Tungsten powder is the main raw material for preparing cemented carbide and many industrial products. Under normal circumstances, tungsten powder can be classified into coarse grain, fine grain, submicron and nano size according to its particle size. Each particle size of tungsten carbide powder has its specific market application.

sales@chinatungsten.com

sales@chinatungsten.com