Tungsten Trioxide / Iron Composite Photocatalyst

- Details

- Category: Tungsten Information

- Published on Tuesday, 06 March 2018 23:19

As far as today's world is concerned, photocatalysis is undoubtedly one of the most promising technologies. It shows the application of solar energy in many aspects, such as photolysis of water to obtain hydrogen energy, treatment of polluted water and so on.

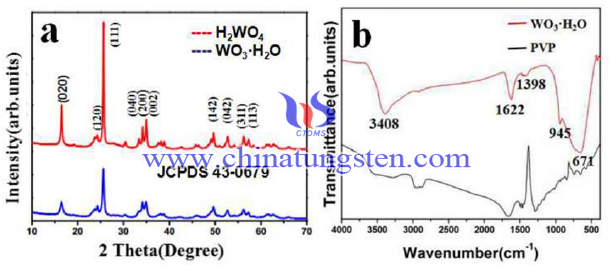

Hydrothermal Synthesis Preparation of Pyrochlore Tungsten Oxide

- Details

- Category: Tungsten Information

- Published on Tuesday, 06 March 2018 23:11

Pyrochlore-type tungsten oxide is a special form of tungsten trioxide, which uses the WO6 octahedron as the structural unit to form a layered structure with circular tunnels through the corner top of the rigid skeleton of W-O. Due to its special physical and chemical properties, it is widely used in the fields of catalysis, sensing, electronics and other materials science.

Preparation of Tungsten Nickel Alloy Rods for Nuclear Power Plant

- Details

- Category: Tungsten Information

- Published on Tuesday, 06 March 2018 22:58

The power generated by a nuclear power plant reactor is generally controlled by lifting or reducing the control rod components in the reactor core. The fuel assembly of modern reactor core typically uses two types of rod control components to control reactivity, namely the rod and beam control assembly (RCCA) and the ash rod control module (GRCA). Both are made up of a number of neutron absorbers fastened to a common hub disk or a multi - foot frame at the top of its top.

The Strategy of Recovery and Utilization of Tungsten Tailings for Plastic Packing

- Details

- Category: Tungsten Information

- Published on Tuesday, 06 March 2018 22:30

Plastic products are widely used in building materials industry. They are light, cheap, and convenient to use. Mineral used in plastic packing can greatly reduce the cost of plastic products, and has a certain role in enhancing the application of tungsten tailings as plastic filler.

Tungsten Oxide Metal Doping

- Details

- Category: Tungsten Information

- Published on Tuesday, 06 March 2018 11:45

Metal doping refers to a variety of substances mixed together. In the chemical, materials and other fields, doping generally refers to the incorporation of small amounts of other elements or compounds in such materials or substrates to improve the properties of a material or substance. Doped materials, substrates can produce specific electrical, magnetic and optical properties, so that it has a specific value or use.

Tungsten Oxide Structural Dimension

- Details

- Category: Tungsten Information

- Published on Tuesday, 06 March 2018 11:42

Tungsten oxide materials by dimension can be divided into zero-dimensional nanosphere, one-dimensional nanofibers and nanotubes, two-dimensional nanosheets and three-dimensional interconnect structure.

Tungsten Oxide Lateral Heterojunction

- Details

- Category: Tungsten Information

- Published on Tuesday, 06 March 2018 11:34

The tungsten oxide lateral heterostructure is in principle achieved by continuously growing the second material at the edge of the existing area of the first material. The tungsten oxide lateral heterojunction structure can be prepared by in situ adjustment of its gas phase reactant during the growth of two-dimensional tungsten oxide crystals. Characterization of Raman and photoluminescent maps shows that it has a clear structure and optical modulation.

Tungsten Oxide Electrocatalytic Hydrogen Evolution

- Details

- Category: Tungsten Information

- Published on Tuesday, 06 March 2018 11:28

Hydrogen production hydrogen reaction speed depends very much on the electrocatalyst. To adapt to industrial production, electrocatalysts not only have a low overpotential, but also to the low price, rich in content and to have good cycle stability and catalytic stability. Tungsten oxide is one of the materials commonly used as a hydrogen evolution reaction electrocatalyst. Compared with Pt and other metals, it is cheap and rich in content. And tungsten oxide can form tungsten bronze with high electron and proton conductivity in a sulfuric acid electrolyte.

Tungsten Oxide Heterojunction CVD Method

- Details

- Category: Tungsten Information

- Published on Tuesday, 06 March 2018 11:24

The most common method for preparing tungsten oxide heterojunctions is chemical vapor deposition (CVD). The basic principle of the CVD method is to grow a two-dimensional crystal on a tungsten oxide substrate, and then grow different two-dimensional materials on the basis to form a two-dimensional heterogeneous structure. The main operation procedure is to pass the reactant into the reaction vessel in the form of gas and then to deposit it on the substrate as a solid after the chemical reaction takes place.

Green Recycling of Tungsten Waste

- Details

- Category: Tungsten Information

- Published on Monday, 05 March 2018 22:37

Owing to the extensive exploitation of tungsten ore, the amount of tungsten raw resources has decreased sharply. In the face of the continuous reduction of tungsten resources, the recovery of tungsten from tungsten waste has become an important breakthrough to alleviate the shortage of raw materials. The hard alloy grinding material is the main source of tungsten recovery because of the high grade of tungsten.

sales@chinatungsten.com

sales@chinatungsten.com