Microwave Oven Magnetron Thorium Tungsten Wire Carbonization Secret

- Details

- Category: Tungsten Information

- Published on Wednesday, 06 June 2018 16:29

In order to improve the stability of magnetron launch, carbonization of magnetron made of thorium tungsten wire is required.

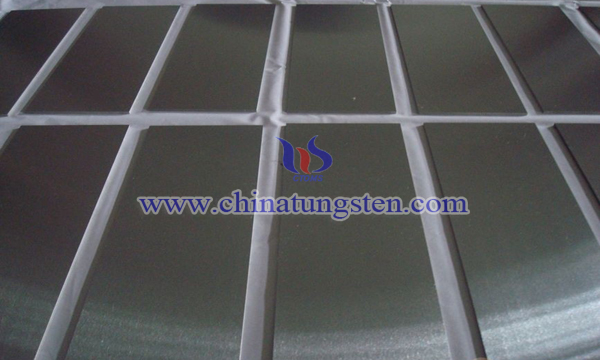

Large Single Heavy Tungsten Plate Target Manufacturing Key Points

- Details

- Category: Tungsten Information

- Published on Wednesday, 06 June 2018 16:08

The large single heavy tungsten plate tungsten target material is mainly used for the coating of the photovoltaic element substrate. The tungsten plate used in this field has a large size, the weight of the single plate is 80 to 150 kilograms, and it has the characteristics of high temperature resistance and good compactness.

Tungsten Smelting Wastewater Recycling by Ion Exchange Method

- Details

- Category: Tungsten Information

- Published on Wednesday, 06 June 2018 15:51

In the process of the production of ammonium para tungstate by ion exchange, a large amount of waste water will be produced. The wastewater mainly contains tungsten, alkali, chloride ion, ammonia nitrogen, COD, a small amount of arsenic, fluoride ions and other elements. Because of the complexity of the components in the waste water, finding a system and method for comprehensive treatment of tungsten smelting wastewater will help enterprises to save energy and reduce emissions.

Tungsten Carbide Recycling from Waste Tungsten Cobalt Alloy

- Details

- Category: Tungsten Information

- Published on Wednesday, 06 June 2018 15:32

The preparation of high quality cemented carbide has strict requirements for the grain size of tungsten carbide powder, which not only requires the microstructure of WC powder well, the crystallization is complete, the granularity is coarse and uniform, but the degree of aggregation can not be too high. This is also the reason why there are few high quality coarse grained cemented carbides made from recycled tungsten in China.

High Purity Tungstate Preparation from Direct Extraction Method

- Details

- Category: Tungsten Information

- Published on Wednesday, 06 June 2018 15:26

For many years, researchers have been innovating and improving the preparation methods of ammonium tungstate solution. Some scholars have invented a method of producing high purity tungstate from the decomposition of tungsten ore.

Tungsten Titanium Alloy Target Material Manufacturing Process

- Details

- Category: Tungsten Information

- Published on Wednesday, 06 June 2018 15:02

Tungsten has high altitude, high corrosion resistance and excellent surface adhesion, which makes tungsten titanium (W-Ti) an ideal solution to prevent the dense layer of the diffusion of foreign atoms. In the metallizing process of semiconductor chip, the tungsten titanium alloy containing 10wt% titanium is often used as a diffusion barrier and bonding layer to separate semiconductors and metallized layers, such as aluminum and silicon or copper and silicon.

Tungsten Slender Mud Recycling Strategy

- Details

- Category: Tungsten Information

- Published on Saturday, 02 June 2018 11:20

In the process of beneficiation, the tungsten mine has a large amount of fine slime, which generally accounts for about 8%-10% of the ore. The recycled rate of the conventional tungsten slender mud process is generally low, about 20 - 30%. Therefore, the comprehensive recycle process and application of tungsten slender mud can be used to improve the comprehensive recycled rate of tungsten slender mud, reduce the waste of resources and reduce the cost of mineral processing. It is of great importance to increase the economic efficiency of enterprises.

Electrochromic Glass Coated Tungsten Nickel Alloy Target

- Details

- Category: Tungsten Information

- Published on Saturday, 02 June 2018 11:08

The chromism and coating quality of tungsten nickel alloy target produced by the existing technology are still not stable enough, resulting in low yield and high cost of electrochromic glass, more wastes such as waste acid and other pollutants are produced.

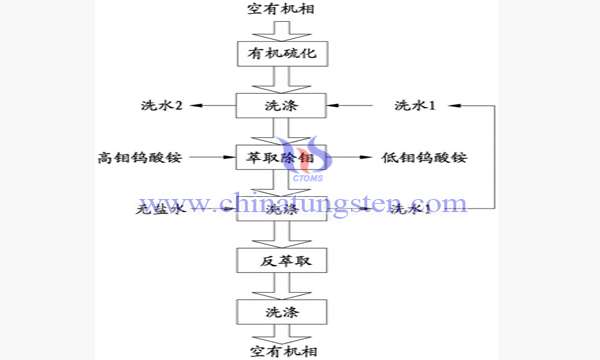

Tungsten and Molybdenum Separation by Quaternary Ammonium Salt Extraction

- Details

- Category: Tungsten Information

- Published on Saturday, 02 June 2018 10:55

Separation of tungsten and molybdenum has been the focus of tungsten and molybdenum smelting technology research and development. Some researchers have proposed a method of extraction and separation of tungsten and molybdenum by extraction and separation of ammonium tungstate solution by N263- paraoctanol - kerosene system, which consists of 20% N263, 20% isooctanol and 60% kerosene, O/A=1:1.

Tungsten Mineral Raw Materials Decomposition by Far Infrared Hot Pressing

- Details

- Category: Tungsten Information

- Published on Saturday, 02 June 2018 10:35

In order to optimize the technological process, energy saving and emission reduction, the researchers put forward a far infrared hot press decomposition of tungsten mineral raw materials to achieve a clean production process for the full decomposition of tungsten minerals in wet tungsten smelting. The characteristics of the process are as follows:

sales@chinatungsten.com

sales@chinatungsten.com