Hard Alloy for Wear-resisting and Acid Resistant and Acid Resistant Drilling

- Details

- Category: Tungsten Information

- Published on Sunday, 17 June 2018 17:39

With the continuous development of the hard alloy industry and the quickening of the pace of deep-sea engineering, the exploration of oil and gas is becoming more complex in the geological conditions and physical environment. Some areas with high H2S and CO2 content and high sulfur bearing geological environment have become the focus of oil and gas exploration, and this has also raised higher requirements for the hard joint gold for drilling.

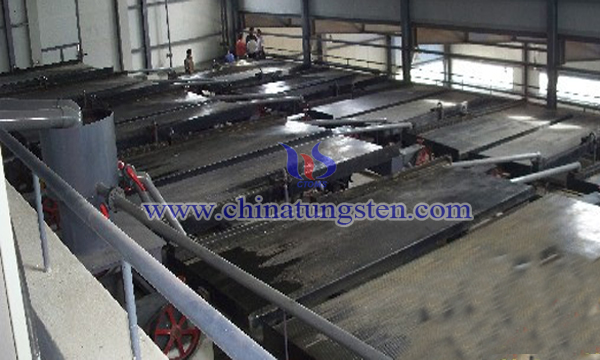

Tungsten Ore Reelection Omnipotent Rocking Bed

- Details

- Category: Tungsten Information

- Published on Sunday, 17 June 2018 17:31

The table is commonly used in separation of fine ore dressing equipment, processing of metal ore can tick size in the 3 - 0.019 mm particles. After more than 100 years of development, the performance of ore dressing rocking bed has been perfected, mainly around the target of high efficiency and low space occupancy rate, and great progress has been made.

High Proportion Tungsten Alloy Preparation by Two Times Sintering Process

- Details

- Category: Tungsten Information

- Published on Sunday, 17 June 2018 17:24

The present sintering process of high proportion tungsten alloy is generally used in primary sintering. The high ratio of waste products and low utilization ratio of raw materials make high production cost of high gravity tungsten alloy. For example, the utilization ratio of raw material for 90WNiFe alloy by existing technology is only 60%, and the raw materials of 93WN iFe alloy sintered by existing technology are used. The utilization rate is only 63%, and the waste of raw materials is serious.

Tungsten Smelting Wastewater Simple and Effective Comprehensive Treatment

- Details

- Category: Tungsten Information

- Published on Sunday, 17 June 2018 17:15

China's Tungsten smelting has about 20000000 cubic meters of wastewater every year. Most of the production enterprises have serious problems of ammonia nitrogen, arsenic, phosphorus and fluoride emissions. How to solve the environmental pollution of tungsten smelting industry, protect river water and people's health, and realize the sustainable development of tungsten industry is of great significance.

Fine-grained Tungsten Carbide

- Details

- Category: Tungsten Information

- Published on Sunday, 17 June 2018 17:05

Carbides are used to produce cutters for cutting or forming objects such as end milling, knives and scissors. In this automatic cutting or automatic molding process, hard alloy tools need to be subjected to extremely harsh conditions.

Gravitational Recycle of Tungsten Tailings from Flannelette Blanket Chute

- Details

- Category: Tungsten Information

- Published on Sunday, 17 June 2018 16:57

Tungsten is nonferrous metal, the distribution of the crust is small, mainly in the state of tungstate and tungsten, the main tungsten minerals are wolframite (Fe, Wn) Wo4 and scheelite CaWo4, which are mostly vein deposits and their Wo3 content is between 0.4 and 2%. Wo3 reaches more than 65% and becomes tungsten concentrate before it can be used to smelt tungsten or extract compounds and metals.

Spherical Ammonium Para Tungstate by Ball Milling Method

- Details

- Category: Tungsten Information

- Published on Sunday, 17 June 2018 16:35

Ammonium para tungstate (APT) is composed of ammonium tungstate solution prepared by crystallization unit operation. The main methods of evaporation and crystallization, crystallization and freezing crystallization. APT morphology, particle size and particle size distribution on the performance of the subsequent oxidation of tungsten, tungsten powder, tungsten carbide powder has a great influence.

Ammonia Nitrogen Recycling by Tungsten Smelting and Extraction Method

- Details

- Category: Tungsten Information

- Published on Sunday, 17 June 2018 16:20

In tungsten smelting, ammonium chloride is recycled by evaporation crystallization, and ammonia nitrogen is recycled. The existing technology has low ammonia nitrogen recovery rate and high energy consumption of evaporation crystallization. Low recycling rate will cause poor working environment and waste water difficult to reach standard discharge. At the same time, the cost of evaporation recycling will also be higher and higher. Therefore, it is of great significance to develop a low energy recovery process to replace the current evaporation crystallization process.

Phosphorus Decomposes Wolframite and Scheelite Mixing Ore

- Details

- Category: Tungsten Information

- Published on Sunday, 17 June 2018 11:44

Although tungsten is mainly derived from scheelite, there is a considerable proportion of wolframite. The largest tungsten ore reserves in China are 747 thousand T, and the ratio of wolframite and scheelite is 3:7. For such minerals, the sulphuric acid phosphoric acid mixed acid process is used directly, and the wolframite does not react completely, and all of them enter the leaching residue. In fact, it is difficult to decompose wolframite without sulphuric acid phosphoric acid mixed system. Even if other acids are used, the leaching reaction of wolframite is very slow.

Wolframite and Scheelite Ore High Efficiency Flotation

- Details

- Category: Tungsten Information

- Published on Sunday, 17 June 2018 11:25

In the mineral processing of tungsten minerals, single scheelite or wolframite recovery of tungsten concentrate is easy, but it is relatively difficult for tungsten ores in scheelite and wolframite ore bodies, mainly because the heavy magnetic separation is difficult to have good indicators in the recycling of fine-grained scheelite and wolframite, and therefore, Flotation is usually used in ore mixing.

sales@chinatungsten.com

sales@chinatungsten.com