Pure Sodium Tungstate Preparation from Alkali Leaching Solution

- Details

- Category: Tungsten Information

- Published on Monday, 02 July 2018 11:53

At present, in the process of producing ammonium tungstate solution by tungsten mine, the technology of separating P, As, Si and Mo from tungsten ore to produce high pure ammonium tungstate solution has the classical chemical method, the current extraction method and the ion exchange method. The current extraction process is the free alkali in the inorganic acid neutralization solution, the silicate hydrolysis, most silicon is removed by silicic acid precipitation, then the P, As and the remaining silicon are removed by the magnesium salt or ammonium magnesium salt, and the Mo is separated by the precipitated MoS3 method, and the purified sodium tungstate solution.

Quaternary Ammonium Salt Direct Extraction Method

- Details

- Category: Tungsten Information

- Published on Monday, 02 July 2018 11:42

At present, in the process of producing ammonium tungstate solution by tungsten mine, the technology of separating P, As, Si and Mo from tungsten ore to produce high pure ammonium tungstate solution has the classical chemical method, the current extraction method and the ion exchange method.

High Efficiency Determination of Tin in Tungsten Concentrate

- Details

- Category: Tungsten Information

- Published on Monday, 02 July 2018 11:20

In the process of tungsten concentrate smelting, the existence of tin will have a serious effect on the mechanical and physical properties of the tungsten concentrate. Therefore, according to the national standard, the quality standard of the product submitted in the process of selling tungsten concentrates is required to report the content of tin in the tungsten concentrate and to determine the content of tin.

The Method of Making Tungsten Coil with Thorium Tungsten Wire

- Details

- Category: Tungsten Information

- Published on Monday, 02 July 2018 10:45

The tungsten coil used in the cathode of the magnetron is made of the thorium tungsten wire in a spiral shape. It has the ability to emit electrons by heating the current through the current to the specified temperature. The cathode has the advantages of short heating time and strong anti electronic bombardment.

Tungsten Recycling from Tantalum Niobium Smelting Wastewater

- Details

- Category: Tungsten Information

- Published on Monday, 02 July 2018 10:22

China has successfully produced high-purity tantalum niobium products from various tantalum niobium ores, and it has formed a considerable scale of production capacity. In the process of wet production of tantalum and niobium, a large number of rare elements (such as Ti, Cr, Re, W, Ni, etc.) as well as common elements (such as Sn, Ca, Fe, Mo, etc.) are associated with the raw mineral.

Simple Recovery of Wolframite and Scheelite in Tungsten Slender Mud

- Details

- Category: Tungsten Information

- Published on Monday, 02 July 2018 10:08

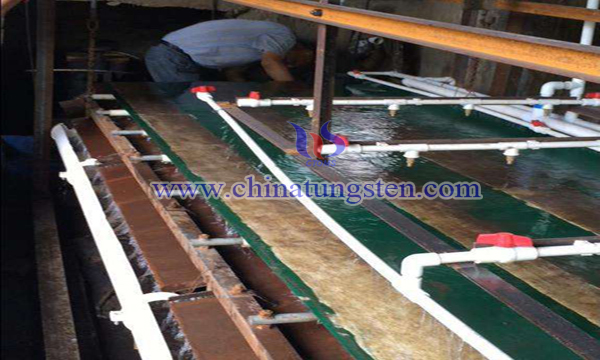

The recovery rate of tungsten mineral resources is only 60-70%, and the recovery rate is about 80%. The recovery rate of mining, selection and metallurgy is only about 50%, of which most of tungsten is lost in tungsten mud. There are more and more scheelite resources of "poor, fine and miscellaneous", and the scheelite is just as brittle as wolframite, it is easily comminuted in the process of grinding and it is lost in fine mud.

Tungsten Molybdenum Separation from Phosphotungstic Acid / Phosphotungstate solution

- Details

- Category: Tungsten Information

- Published on Sunday, 01 July 2018 18:13

Tungsten and molybdenum have the same atomic radius and similar electronic structure, showing very similar chemical properties. Therefore, tungsten and molybdenum are often found in scheelite in nature. Tungsten and molybdenum separation is a technical problem in tungsten smelting process.

Synergetic Decomposition of Tungsten Molybdenum Ore by Parathion Mixed Acid System

- Details

- Category: Tungsten Information

- Published on Sunday, 01 July 2018 18:00

Tungsten and molybdenum are often co born in scheelite in nature. At present, China's high molybdenum resources account for about 50% of the total industrial reserves of tungsten, and the tungsten resources of molybdenum resources account for about 1/3. This kind of ore is difficult to choose. It is a major problem that troubles the tungsten smelting industry.

How to Solve the Tungsten Tin Separation Problem

- Details

- Category: Tungsten Information

- Published on Sunday, 01 July 2018 17:54

China is the world's largest tungsten producing country and the main producer of tin, millions of tons of tungsten tin symbiotic minerals are separated and enriched by the methods of general gravity separation and flotation or magnetic separation.

Tungsten Trioxide Recycling from Tungsten Slag

- Details

- Category: Tungsten Information

- Published on Sunday, 01 July 2018 17:40

Tungsten slag is a waste residue produced by tungsten smelting enterprises in the process of pressure leaching. The pressure leaching process is based on a standard tungsten ore with a content of 65% of tungsten ore after ore dressing and adding additives. Under high temperature and high pressure alkaline conditions, after wet decomposition or fire decomposition, tungsten primary products such as sodium tungstate, calcium tungstate and ammonium para tungstate are obtained and the fineness is more than 100 orders of tungsten residue, each of which is produced. The output of a ton of WO3 primary products and the discharge of about 0.8 tons of tungsten slag at the same time, with the exhaustion of resources, the recovery of tungsten slag is of great significance.

sales@chinatungsten.com

sales@chinatungsten.com