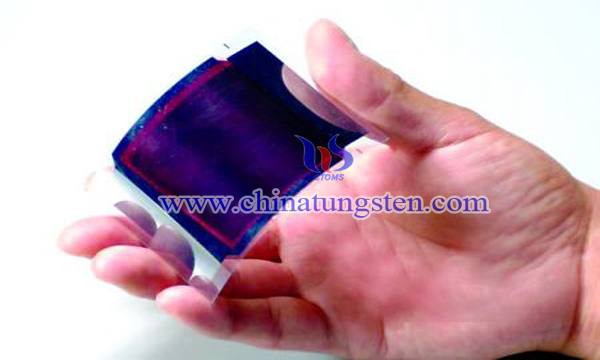

Tungsen Trioxide Electrochromic Nanofilm

- Details

- Category: Tungsten Information

- Published on Monday, 23 July 2018 18:43

Electrochromism refers to the phenomenon that displayed by some materials of reversibly changing color under the action of an applied electric field. Electrochromic device only needs a small voltage (about 2V) to work, and the original color or fading state can be maintained in the open circuit, so the energy consumption is less.

New Manufacture Process for Tungsten-Oxide Ethanol Sensor

- Details

- Category: Tungsten Information

- Published on Monday, 23 July 2018 18:37

The ethanol gas sensor can detect the ethanol content in drunk driving inspection or industrial production, So as to reduce or avoid traffic accidents or production safety accidents. In recent years, the development of ethanol sensors has become more extensive and in-depth, and the ethanol sensing characteristics of tungsten oxide have received extensive attention from researchers.

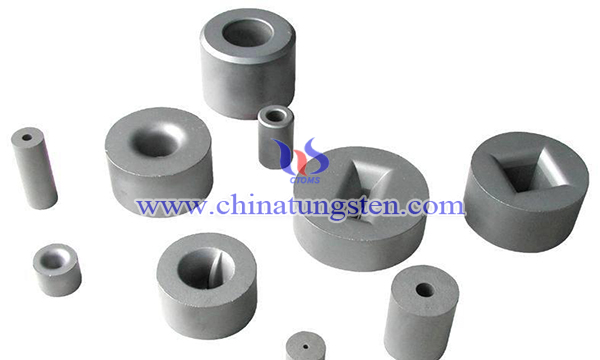

Short Run Production of Tungsten Carbide Die

- Details

- Category: Tungsten Information

- Published on Sunday, 22 July 2018 20:33

Market Analysis of Tungsten Carbide Die

- Details

- Category: Tungsten Information

- Published on Sunday, 22 July 2018 20:30

Design and Manufacture of Tungsten Carbide Die

- Details

- Category: Tungsten Information

- Published on Sunday, 22 July 2018 20:27

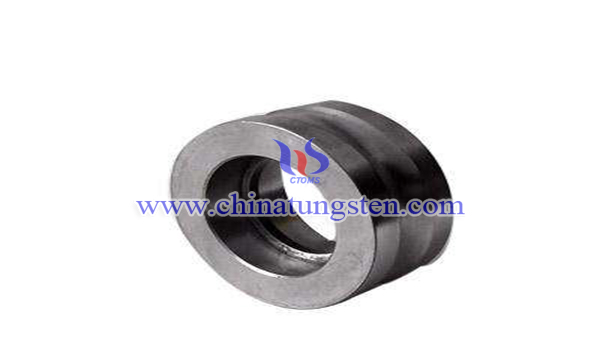

Grinding Process of Tungsten Carbide Drawing Die

- Details

- Category: Tungsten Information

- Published on Sunday, 22 July 2018 20:24

Repair Process of Tungsten Carbide Drawing Die

- Details

- Category: Tungsten Information

- Published on Sunday, 22 July 2018 20:22

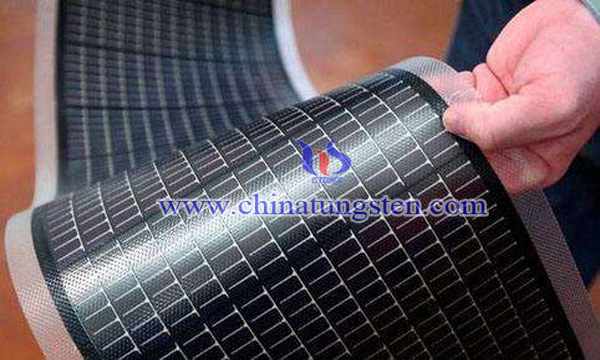

Graphene-Modified Semiconductor Photoelectrode

- Details

- Category: Tungsten Information

- Published on Friday, 20 July 2018 18:08

Photoelectrocatalytic water decomposition using semiconductor is a very attractive technique to solve the global energy and environmental problems. This technique converts the solar energy into hydrogen energy by water decomposition. Photoelectrode is an important part of this technique. Graphene-modified semiconductor photoelectrode is an excellent photoelectrode of within.

Nanometer Tungsten Trioxide Film

- Details

- Category: Tungsten Information

- Published on Friday, 20 July 2018 18:03

The solar photoelectrochemical (PEC) cell for hydrogen production is a technique based on solar energy and water. The products are hydrogen and oxygen. Both products are renewable. Thus, this technique has no harm to the environment, and can be applied on a small-scale production and mass production. Therefore, this technology is the most attractive hydrogen production direct use the solar energy

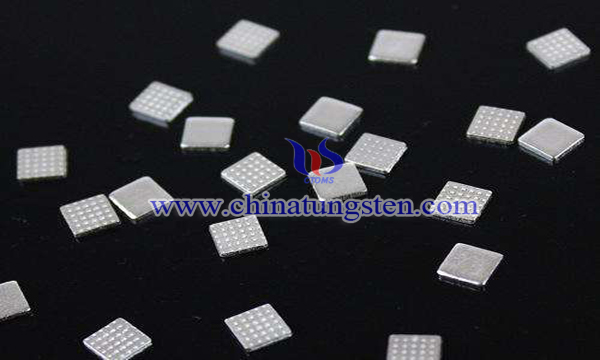

Silver-Nickel-Tungsten Contact

- Details

- Category: Tungsten Information

- Published on Friday, 20 July 2018 16:19

Silver-nickel contacts are widely used in various low-voltage electrical appliances due to their good thermal conductivity, low and stable contact resistance, and excellent processing properties. However, due to the weak anti-welding performance, the applications of silver-nickel contacts are limited.

sales@chinatungsten.com

sales@chinatungsten.com