Abstract Tungsten from Tungsten Oxide Limonite

- Details

- Category: Tungsten Information

- Published on Friday, 27 July 2018 09:05

Tungsten oxide limonite is a multi metal component, containing tungsten oxide 0.3%-0.6%, iron 26%-31% and other elements such as silicon, aluminum and calcium. It is difficult to be separated and enriched by traditional ore dressing method, it can not be enriched in high grade like other tungsten ores. At present, the ore can only be used as the raw material for cement production. A large amount of precious metal tungsten is irreversibly disappearing in building materials.

A Method for Tungsten Extraction in Alkaline Medium

- Details

- Category: Tungsten Information

- Published on Thursday, 26 July 2018 18:40

Pressure leaching and water leaching are two mature methods for industrial leaching of tungsten from tungsten ore. The leachate obtained by the above two leaching methods is a mixed solution of sodium tungstate and sodium carbonate, which usually contains a small amount of impurities such as P, As, Si, etc. and this solution is a soda leaching solution containing a tungsten material.

A Preparation Method of Tungsten-Titanium Alloys with Arc Melting

- Details

- Category: Tungsten Information

- Published on Thursday, 26 July 2018 18:37

Tungsten is a very important non-ferrous metal. It has a series of properties such as high density and high strength. It is commonly used in counterweight materials, shielding materials, military firing materials, semiconductor materials, etc.

A Froth Floatation Method Using Low-Tungsten Tin Concentrate to Produce APT

- Details

- Category: Tungsten Information

- Published on Thursday, 26 July 2018 18:32

In ore deposits, tungsten is more or less symbiotic with minerals such as tin, copper, antimony, bismuth or molybdenum. Tungsten ore is separated by gravity concentration method, froth flotation method, or gravity concentration-froth flotation process. However, for the associated tungsten in the complex tin concentrate, it is difficult to separate by using the conventional ore separation methods. When the tin concentrate containing ≥1%, the high melting point of tungsten will affect the smelting of tin concentrate.

A Preparation Process of Bismuth Tungstate by Sol-Gel-Hydrothermal Method

- Details

- Category: Tungsten Information

- Published on Thursday, 26 July 2018 18:28

Environmental pollution is a major challenge facing by humans today. The use of photocatalytic technology to control environmental problems is one of the most active research fields. Finding high-efficiency photocatalysts is a top priority in this field. Bismuth tungstate (Bi2WO6) photocatalyst is considered to be a potential excellent visible light catalytic material due to its unique electronic structure, excellent visible light absorption capacity and high organic matter degradation ability.

Recovery Method of Tungsten from Fine-Grained Tungsten Ore Tailings

- Details

- Category: Tungsten Information

- Published on Thursday, 26 July 2018 18:24

In the association deposit of scheelite and wolframite, the ratio of scheelite to wolframite is 1:9 to 9:1. Although the recovery rate of black and white tungsten mixed flotation has reached more than 80%, the total recovery of tungsten is only about 60%, which is mainly due to the low recovery rate of fine-grained tungsten ore in the separation process of scheelite and wolframite mixed concentrate.

Tungsten in the Steam Turbine Blades

- Details

- Category: Tungsten Information

- Published on Thursday, 26 July 2018 18:17

A turbine blade is the essential part in a steam turbine. Turbine blades are subjected to high temperature and high pressure steam, and they are subjected to large bending moments during operation. The moving blades in high speed operation are also subjected to high centrifugal force; the blades in the wet stream areaare subject to electrochemical Corrosion and water droplets impinge on moving blades are also subject to very complex exciting forces. Therefore, the steel for blade should meet the following requirements: high temperature mechanical properties and anti-creep property; high resistance to vibration damping; high structural stability; good corrosion and erosion resistance.

New Production Method for Tungsten-Titanium Target

- Details

- Category: Tungsten Information

- Published on Wednesday, 25 July 2018 18:54

Physical vapor deposition (PVD) is widely used in optical industry, electronic industry, and information industry. The applications of PVD include integrated circuits, liquid crystal displays (LCD), industrial glass, camera lenses, information storage, ships, chemicals, etc. The alloy target used in PVD is one of the most important raw materials in the manufacturing process of integrated circuits and liquid crystal displays.

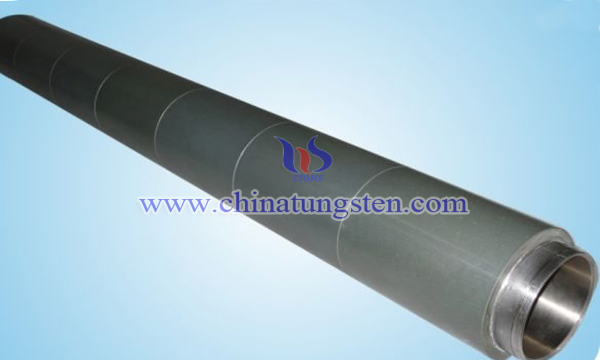

Production Method of Rotary Target Using Tungsten-Molybdenum Alloy

- Details

- Category: Tungsten Information

- Published on Wednesday, 25 July 2018 18:49

Thin-film-transistor (TFT) film has the advantages of high responsivity, high brightness and high contrast. It is one of the basic materials in many industries. Therefore, it is widely used in the fields of solar cells, liquid crystal displays and plasma displays. In recent years, along with the rapid development of high-end displays, tungsten Molybdenum alloy rotary targets have become an important material for the preparation of TFT films.

High-purity Ammonium Paratungstate Preparation Process

- Details

- Category: Tungsten Information

- Published on Wednesday, 25 July 2018 18:42

Ammonium paratungstate hydrate is an intermediate for the production of tungsten metal, tungsten-containing catalysts, tungsten-based hard materials (such as tungsten carbide) or sputtering targets. The preparation is carried out mainly by digesting or melting a slag containing tungsten concentrate or tungsten with acid or base, followed by purification, and the purification stage includes a precipitation process and a liquid-liquid extraction. The purified solution is usually concentrated by evaporation to finally crystallize the ammonium paratungstate hydrate.

sales@chinatungsten.com

sales@chinatungsten.com