Tungsten Oxide Quantum Dots and Tungsten Oxide Nanowires Absorbing Materials

- Details

- Category: Tungsten Information

- Published on Tuesday, 31 July 2018 23:04

Tungsten oxide has the unique physical properties such as photochromism, electrochromism, thermochromism and gas sensitivity. The color changes can be achieved by changing the wavelength, changing the temperature or applying voltage. Therefore, the transition metal tungsten oxide can be used in many fields, such as various sensors, electronic devices, and so on, because of its advantages. The development of Vietnam has become a hot topic all over the world.

Tungsten Bronze Preparation Strategy

- Details

- Category: Tungsten Information

- Published on Tuesday, 31 July 2018 22:50

The band gap of tungsten bronze (MxWO3) is about 2.7 eV, and it has free-migrating electrons. It is one of the most suitable materials for transparent and thermal insulation. Research shows that tungsten bronze materials have better transparency and heat insulation than ITO, ATO, AZO and GZO. It is one of the effective means of saving energy for building or automobile glass. It is a kind of high quality filter for infrared light, and it can be coated on the surface of glass or plastic film to form a transparent insulation coating.

Tungsten Wastewater Chemical Precipitation Zero Discharge

- Details

- Category: Tungsten Information

- Published on Tuesday, 31 July 2018 22:27

In the process of hydrometallurgy of tungsten, sodium tungstate solution is adsorbed by ion exchange resin, and the wastewater is discharged directly. Due to the limitations of the ion exchange process and the complexity of the raw materials, the WO3 content in the wastewater after ion exchange is always maintained at a certain value, most of which are larger than 0.05g/l. This not only increases the cost of production and consumption of tungsten resources, but also increases the cost of environmental management.

High Purity Tungsten Carbide Recycle from Waste Tungsten Cobalt Alloy

- Details

- Category: Tungsten Information

- Published on Tuesday, 31 July 2018 22:13

Generally speaking, it is a good way to separate tungsten carbide powder by electrolysis. The methods of recovering tungsten carbide by the usual electrolysis process are not completely electrolyzed, the cobalt can not be completely separated and removed and the surface wear of the crusher and ball mill is introduced into the process. The Fe, Ni, Co and other impurities in the tungsten carbide powder are over 0.6%, respectively, and the production of high performance cemented carbides is produced. There is a big gap between the high purity technical standards of Fe, Ni and Co, which are not more than 0.1%, so that the scope of the use of tungsten carbide in the electrolysis process is greatly limited.

Influence of Tungsten Carbide Button Bit on Rock Drilling Speed

- Details

- Category: Tungsten Information

- Published on Tuesday, 31 July 2018 17:59

The rock drilling speed is one of the important indicators for the quality of tungsten carbide button bit. In the case of fixed models, lithology, operating systems, etc., the geometric parameters of the bit have a great influence on the rotational speed. The geometric parameters of the button bit include its shape, number, diameter, the distribution of button, the powder discharge system, the tooth height, incline angle of side teeth and so on

Strengthening Button Methods of Tungsten Carbide Button Bit

- Details

- Category: Tungsten Information

- Published on Tuesday, 31 July 2018 17:49

Strengthening button method of tungsten carbide button bit refers to how to fix the button on the bit in order to support it and guarantee that the displacement and detachment of the button won’t happen during rock drilling.

What is Tungsten Carbide Button Bit?

- Details

- Category: Tungsten Information

- Published on Tuesday, 31 July 2018 17:39

Tungsten carbide button bit is formed by insetting the tungsten carbide button into the bit. Compared with the flake bit, the distribution of button bit is more flexible. The number and position of the side and middle tooth can be determined according to the diameter of gouge and the load of cutting.

Ultrasonic Cleaning Method of Tungsten Carbide Button

- Details

- Category: Tungsten Information

- Published on Tuesday, 31 July 2018 17:25

After tungsten carbide button is turned, grinded or polished, the residual oil, dirt, oxide and so on are tightly combined with the surface of tungsten carbide which will cause serious dirt. It requires that the product should be clean, dry and free from corrosion.

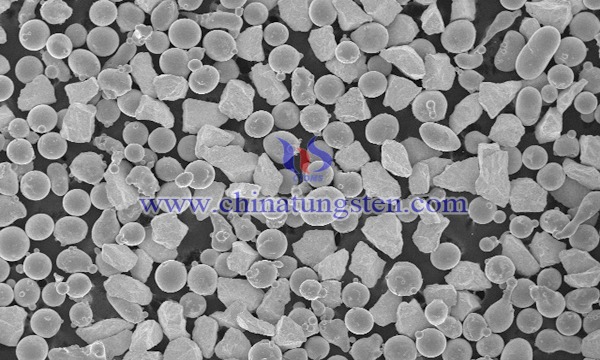

A New Method for the Coarse Grain Tungsten Carbide Manufacturing

- Details

- Category: Tungsten Information

- Published on Monday, 30 July 2018 20:12

The coarse grain tungsten carbide has a series of advantages, such as good crystallizability, less structural defects and large subcrystal size. It is used in the production of hard alloys. The mining tools, stamping dies, drilling and mining tools can also be applied to hard surface materials such as spray and spray welding.

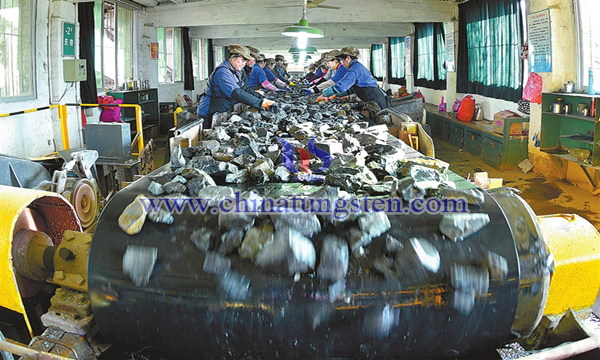

How to Refine Low Grade Tungsten Ore and Tungsten Slag

- Details

- Category: Tungsten Information

- Published on Monday, 30 July 2018 19:50

The advantage of tungsten resources in China is gradually disappearing, the resource crisis is prominent. At present, with tungsten resources becoming more and more complex and difficult to choose, all kinds of high impurity and low grade tungsten ore raw materials will become the main body of raw material treatment for tungsten smelting enterprises in the future. In addition, as China encourages the development of recycling economy, the recovery and utilization of various tungsten smelting residues will also receive more and more attention from enterprises.

sales@chinatungsten.com

sales@chinatungsten.com