A Preparation Method of Plasma-Facing Tungsten Coating in Fusion Reactor

- Details

- Category: Tungsten Information

- Published on Tuesday, 07 August 2018 17:49

Nowadays, the International Thermonuclear Experimental Reactor (ITER) has been built in France. The plasma-facing material is an urgent problem to be solved for ITER and future commercial fusion reactors. It is directly related to whether commercial power generation in fusion reactors can be realized in the future.

Transparency-Changeable Porthole Using Tungsten Oxide Electrochromic Coating

- Details

- Category: Tungsten Information

- Published on Tuesday, 07 August 2018 09:12

Although the porthole of the Boeing 787 has no visor, it can change the transparency. You only need to press the button, and then transparency-changeable porthole will become completely dark. Of course, the captain can also dim directly from the cockpit when the night falls. In addition, because the color change process of this transparency-changeable porthole is gradual, you don't have to worry about the eyes being uncomfortable. What's more, when an unexpected power outage occurs, the portholes become completely transparent and comply with relevant aviation standards. The key is the tungsten oxide electrochromic film applied on the porthole. To understand this, we need to know what is electrochromism ?

Nano-Tungsten Oxide Coating for Smart Sunroom

- Details

- Category: Tungsten Information

- Published on Tuesday, 07 August 2018 09:04

Smart Home makes our home life more comfortable, safer and more convenient! It is also energy-saving and environmentally friendly, and it also makes our life quite artistic. The smart sunroom is one of which. The basic characteristic of the smart sunroom is to permit abundant sunlight in. Thus a large area of glass wall has been always applied on it. What makes it smart is the temperature adjustment function, which keeps the room from too warm or too cold. What conflicts is that the major source of heat comes from the sunlight through the glass, wherein the ultraviolet (UV) rays and infrared radiation carries the most percent of heat. Therefore it is necessary to find a heat-insulating coating with ultraviolet sunlight & infrared radiation blocking functions for the glass wall. The nanometer tungsten oxide is considered as a suitable material.

Tungsten Iron Recycle from Tungsten Waste

- Details

- Category: Tungsten Information

- Published on Sunday, 05 August 2018 21:58

Tungsten iron is an important raw material in industry. The use of tungsten iron is very widely used in various industrial fields, such as mine, metallurgy, machinery, construction, transportation, electronics, space and military industry. The traditional tungsten iron is made from wolframite concentrate and mixed in electric furnace by mixing the additive in a certain proportion. This smelting process has difficulties in raw material sources, high requirements for raw materials, high cost and need to be broken by crusher in the process of preparation, resulting in unevenness and other technical problems.

Chemical Precipitation of Nano Tungsten Oxide

- Details

- Category: Tungsten Information

- Published on Sunday, 05 August 2018 21:35

Tungsten metal has high melting point, high hardness, wear resistance, good conductivity and thermal conductivity. It is widely used in the fields of mine, metallurgy, electronics and machinery, and it is also an important raw material for the preparation of hard alloy materials. The rapid development of modern industry has put forward higher requirements for today's cemented carbide materials, and it is necessary to develop hard alloy materials with high hardness, high strength and high wear resistance.

Low Cost Treatment of Tungsten Waste

- Details

- Category: Tungsten Information

- Published on Saturday, 04 August 2018 22:47

Tungsten containing waste is complex, difficult to extract and complicated. This kind of APT is manufactured by traditional methods with long process flow, narrow range of raw materials, large investment in equipment, unstable products and poor economic benefits. In recent years, people have made some explorations in the preparation of ammonium parotungstate from waste materials containing tungsten and achieved some results.

Reclaiming Rubidium from Rubidium Tungsten Ore

- Details

- Category: Tungsten Information

- Published on Saturday, 04 August 2018 22:34

Rubidium (Rb) is a dilute chemical substance, very soft silver white wax metal. It is soft and light, and its chemical properties are more active than potassium. It can be used for the production of special glass, micro high energy battery and crystal scintillation counter. The minerals containing rubidium are mica and potash feldspar, mainly in wolframite and scheelite.

Production Method of Near-Spherical Tungsten Powder

- Details

- Category: Tungsten Information

- Published on Friday, 03 August 2018 19:15

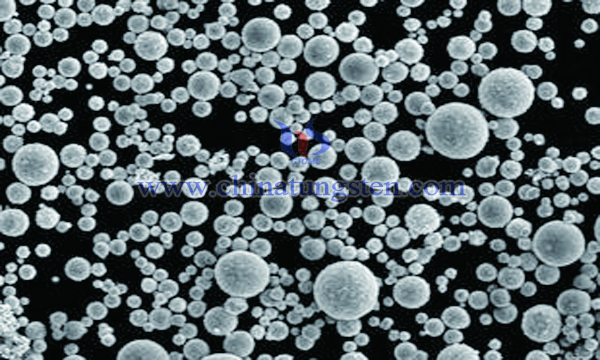

The tungsten powder commonly used in the industry is mainly obtained by reducing tungsten oxide with hydrogen. Such tungsten powder has irregular particle shape, poor fluidity, low bulk density, and it is difficult to obtain a tungsten body with continuous micropores by sintering. In recent years, the demand for near-spherical or spherical tungsten powder has increased day by day, and is widely used in powder metallurgy processes such as porous material preparation, thermal spraying and injection molding.

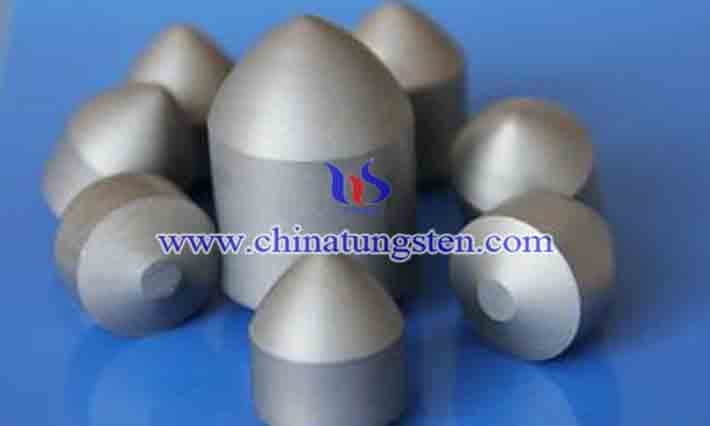

Invalidation Mode of Tungsten Carbide Mining Button

- Details

- Category: Tungsten Information

- Published on Friday, 03 August 2018 18:26

The tungsten carbide mining button is composed of mining button handle, button head and alloy cutter head. The mining button handle and its cutter head are collectively referred to knife body. Its hardness is 40-45HRC. The pounding tenacity is not less than 49J/cm2.

Tungsten-Lanthanum Alloy Wire

- Details

- Category: Tungsten Information

- Published on Friday, 03 August 2018 18:23

The current tungsten filaments in bulbs are tungsten alloy wires made of ammonium paratungstate (APT) as main material with potassium, aluminum and silicon. This tungsten alloy wire thus has the disadvantages of low cold resistance, low thermal resistance, and poor photoelectric performance. In the process of tungsten wire manufacture, the rotary forging and drawing process will harden the tungsten alloy, and increases internal stress, thus it is easy to break when pulling; this increases the difficulty of production. The hardening of the alloy and the presence of internal stresses result in a shorter service life of the tungsten wire and poorer impact resistance, and the filament is prone to sagging after use.

sales@chinatungsten.com

sales@chinatungsten.com