High Purity Tungsten Reduction Technology

- Details

- Category: Tungsten Information

- Published on Saturday, 28 April 2018 16:16

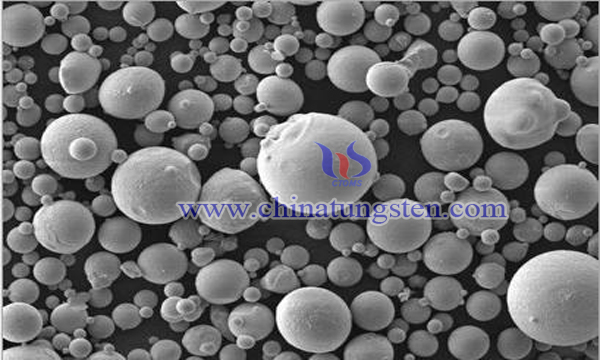

High purity tungsten, which means more than 99.995% of the purity of tungsten, is a key material for the formation of the diffusion barrier in the process of mass integrated circuit and PVD coating. High purity tungsten powder has become an indispensable raw material for the microelectronics industry.

Some scholars have put forward the preparation method of high purity tungsten powder for scale integrated circuit, which aims to make the production of high purity tungsten powder with purity not less than 99.999%, and to ensure the controllability of the particle size and morphology of tungsten powder. The process is as follows:

(1) Using the industrial 0 grade ammonium parotungstate in GB/T10116-2007 as raw material, the three band rotary tube air furnace is calcined to form yellow tungsten. The temperature of the three zone is 550 + 5°C, 600 + 5°C, 600 + 5°C. The concentration of yellow tungsten is dissolved in 10% ammonia water at 50-60°C, the initial concentration of solution is 200-300g/L, and the dissolution is about 4-8h, and then the ammonium tungstate solution is formed.

(2) 10μm and1μm polypropylene filters were selected for two stage filtration of Fe (OH)3, Ca (OH)2 and other insoluble substances in ammonium tungstate solution.

(3) The filtered ammonium tungstate solution is evaporated and crystallized at 90-120°C in the enamel reaction kettle. The stirring frequency is 50Hz~80Hz, and the crystal mother liquid density reaches 1.08-1.1g/cm3 and then stops the crystallization. At this time the crystallization rate is 60-70%.

(4) A centrifuge equipped with polypropylene filter is used to separate the wet ammonium metatungstate from the centrifuge, and ammonium metatungstate is cleaned by deionized water to the washing liquid to be transparent and then sent into the hot air circulation oven at 100~120°C for 18 ~ 24h, and the purified ammonium metatungstate after purification is obtained.

(5) The high pure ammonium metatungstate was reduced by a tube reduction furnace with high purity quartz as furnace tube. Hydrogen flux was 60-100L/min, hydrogen dew point was -60°C, reduction temperature was 800-900°C, reduction time 1.5-2h, and the loading thickness was 10-30mm.

The purity of high purity ammonium metatungstate and high purity tungsten powder after purification is detected. The total content of impurities is less than 10ppm, and the purity is more than 99.999%. It can meet the requirements of the large-scale integrated circuit and semiconductor chip packaging industry.

- Tungsten Manufacturer & Supplier, Chinatungsten Online: www.chinatungsten.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com