The Photochromic Mechanism of the Tungsten Trioxide Film

- Details

- Category: Tungsten Information

- Published on Thursday, 09 August 2018 18:24

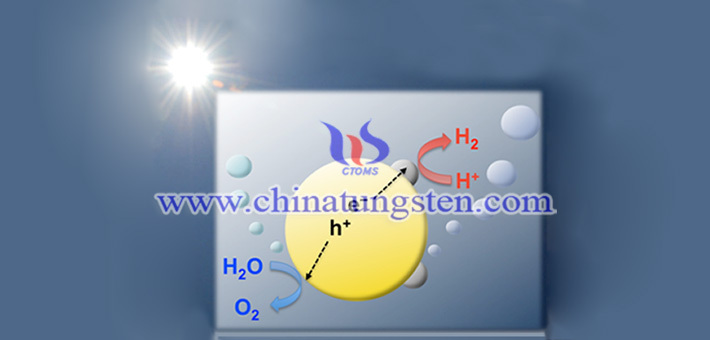

The tungsten trioxide film can be colored by irradiation of light of an appropriate energy. When the tungsten trioxide film is irradiated by light, electrons e- and electron holes h+ are generated, and photogenerated electrons enter the conduction band of the tungsten trioxide. The photo-generated electron holes react with the adsorbed water on the surface of the film to form H+, and then diffuse to the center of tungsten trioxide, thus leads to a difficulty in color change.

Photochromic Properties of Tungsten Bronze

- Details

- Category: Tungsten Information

- Published on Thursday, 09 August 2018 18:17

Tungsten bronze has photochromic properties and can be applied to building windows films and automotive insulation films (smart glass). However, there are currently few studies on this.

Tungsten Trioxide - Electrochromic Material

- Details

- Category: Tungsten Information

- Published on Thursday, 09 August 2018 18:09

Tungsten trioxide is an inorganic electrochromic material with excellent electrochromic properties. Electrochromism refers to the phenomenon that the optical properties of a material undergo a reversible change under the action of an applied electric field, and the appearance is a reversible change in color and transparency.

Preparing Tungsten Trioxide Nanoparticles Using Gas Phase Synthesis

- Details

- Category: Tungsten Information

- Published on Thursday, 09 August 2018 17:56

Tungsten trioxide (WO3) is an important n-type semiconductor oxide with a variety of crystal structures. It has been extensively studied due to its unique physical and chemical properties, and has been used in electrochromism, photochromism, catalysts, and sensing materials. In order to further utilize the excellent properties of WO3 and broaden its application fields, one technical approach is to reduce its grain size, namely nanostructured tungsten oxide.

Hydrothermal Method for Preparing Tungsten Oxide Nanowire Ammonia Sensor

- Details

- Category: Tungsten Information

- Published on Thursday, 09 August 2018 17:48

Tungsten oxide is a transition metal oxide n-type semiconductor. Traditionally, tungsten oxide is applied in catalysts, electrochromism, battery electrodes, solar absorbing materials and radar absorbing materials (RAM). In recent years, scientists have focused on its applications as semiconductor materials such as heat-sensitive, pressure-sensitive and gas-sensitive material. The characteristics and applications of tungsten oxide nanocrystalline films in gas sensors, photocatalysis, photoconductivity, etc. are attracting more and more attentions, especially in the field of oxide semiconductor gas sensor applications, tungsten oxide-based material has been considered as one of the most promising new gas sensing materials for detecting NOx, SOx, NH3, H2S and, etc.

A New Synthesized Photocatalyst-Tungsten Trioxide-Graphene Composite Photocatalyst

- Details

- Category: Tungsten Information

- Published on Wednesday, 08 August 2018 19:41

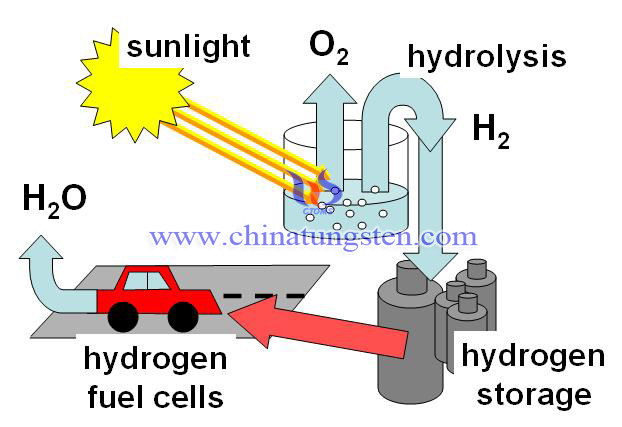

Although fossil fuel based energy supports the development of modern society, it brings up the global issues of global warming and climate change. Thus scientists have been seeking for a clean energy to replace the fossil fuels. The photocatalytic decomposition of water to produce hydrogen is considered as a promising way to solve those environmental issues in the future. The key to make it possible is to find a photocatalyst with required properties.

Why Tungsten Trioxide Is A Promising Photocatalyst Material?

- Details

- Category: Tungsten Information

- Published on Wednesday, 08 August 2018 19:38

Tungsten trioxide (WO3) is one of the earlier studied photocatalysts. There are other promising photocatalysts such as titanium dioxide, iron oxide and so on. But what makes tungsten trioxide one of the earliest materials studied in the field of phtocatalysts? This is due to the light stability of tungsten trioxide, a wide range of sources, and it is environmental friendly. It is no wonder that it will be favored by researchers.

Nanometer Metal Structures Using 3D Printing: Even Tungsten Material Is Achievable

- Details

- Category: Tungsten Information

- Published on Wednesday, 08 August 2018 19:35

At present, one of the difficulties of 3D printing technology is the using of refractory metal for printing, especially metals with high melting points such as tungsten, chromium and bismuth, nor the nanometer powders. This means that it is also difficult to apply 3D printing technology to nanometer tungsten trioxide powder. Over the years, scientists from all over the world have worked on new processes that can be cost-effective and achieve the desired performance requirements.

A Hydrothermal Synthesis Method of Tungsten Trioxide Photochromic Material

- Details

- Category: Tungsten Information

- Published on Wednesday, 08 August 2018 19:30

Tungsten trioxide is an excellent photochromic material that turns blue under ultraviolet light. So, what is photochromism? Photochromism means that compound A can produce product B with different structure and spectral properties through specific chemical formula when subjected to illumination with wavelength λ1, and B can be reversibly generated under the action of light or heat with wavelength λ2.

Six Preparation Methods of Tungsten Trioxide

- Details

- Category: Tungsten Information

- Published on Wednesday, 08 August 2018 19:26

There are six preparation methods of tungsten trioxide include hydrothermal synthesis method, precipitation method, sol-gel method, microemulsion method, gas-liquid reaction method and template method. Some special forms of tungsten trioxide powder can be prepared by different methods. It is due to the existence of this special structure and morphology that the synthesized tungsten trioxide has some new physicochemical properties.

sales@chinatungsten.com

sales@chinatungsten.com