Super-Hydrophobic Coating Using Tungsten Trioxide

- Details

- Category: Tungsten Information

- Published on Wednesday, 08 August 2018 19:21

The super-hydrophobic coating using tungsten trioxide not only has UV resistance (UV or UV), but also has excellent self-cleaning ability, good mechanical properties and stable performance. One of the biggest defects of super-hydrophobic surfaces is poor mechanical properties.

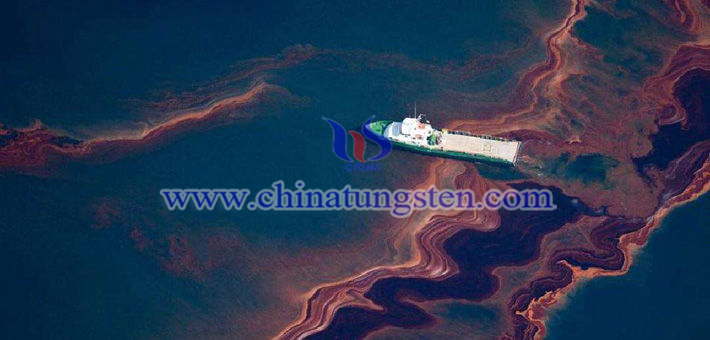

Tungsten Oxide to Be Used In Oil Spill Treatment

- Details

- Category: Tungsten Information

- Published on Wednesday, 08 August 2018 19:16

Tungsten trioxide can be applied to the emulsion separation process in water pollution control, mainly to solve problems such as industrial oily wastewater and oil spill.

Super-Hydrophobic Tungsten Trioxide with Special Wettability

- Details

- Category: Tungsten Information

- Published on Wednesday, 08 August 2018 19:11

Nowadays, research on the wettability of tungsten trioxide materials is not deep enough, although thanks to its unique optoelectronic properties, WO3 has been used in many fields such as photochromism, photocatalysis, electrochromism, sensors and information storage. These areas are also well-known applications of WO3, as many people know that tungsten trioxide is a common n-type semiconductor material. However, the lack of research on the wettability of WO3 will undoubtedly greatly limit the application of tungsten trioxide materials in practical industries. Therefore, the combination of tungsten trioxide material and wetting properties will have important theoretical and practical significance in the increasingly mature and application of WO3 preparation methods.

Why Tungsten Trioxide Is Used in Treatment of Organic Dye Contaminated Water?

- Details

- Category: Tungsten Information

- Published on Wednesday, 08 August 2018 19:07

The tungsten trioxide (WO3) has a band gap energy of about 2.5 eV and has potential photocatalytic ability in visible light having a wavelength of less than 500 nm. Therefore, WO3 has potential application prospects in the treatment of organic dye contaminated water.

Selections of Tungsten Carbide Rock Drilling Button

- Details

- Category: Tungsten Information

- Published on Wednesday, 08 August 2018 17:03

Different operating conditions are matched with different types of tungsten carbide rock drilling button in different shapes and sizes. When we design and select the tungsten carbide button, the load conditions of the rock drilling bits should be taken into considerations. The design of the parabolic button can be done with its reference taper angle.

Defect of Tungsten Carbide Button Tip

- Details

- Category: Tungsten Information

- Published on Wednesday, 08 August 2018 16:52

Tungsten carbide buttons tip were first applied to cone bits and then to DTH bits. The history of button bit in China starts from the cone bits in large diameter and DTH bits.

Tungstate Nanomaterials Preparation by Low Temperature Hydrothermal Method

- Details

- Category: Tungsten Information

- Published on Wednesday, 08 August 2018 10:18

Tungstate nanomaterials have been widely used in many fields, such as optics, electricity, magnetism, conductor/superconductor, catalysis, biology and so on. The synthesis methods of transition metal tungstate materials include sol-gel method, copolymer assisted synthesis, reversed micellar soft template, wet chemical method and solution synthesis.

"Acid Leaching" of Ammonium Paratungstate with Tungsten Waste

- Details

- Category: Tungsten Information

- Published on Wednesday, 08 August 2018 09:57

In the traditional method of producing ammonium paratungstate, the main impurity ions in tungsten waste are phosphorus ions, magnesium ions, iron ions and potassium ions. The major part of the tungsten waste is four kinds of phosphorus ions, magnesium ions, iron ions and potassium ions. At 50 -60°C, the large part of the phosphorus ions and potassium ions in the tungsten residue can not be precipitated, and the magnesium ions are also due to the magnesium ions. With the influence of iron ions, most of the tungsten slag produced will be lumpy when the reaction is finished.

Autoclaved Bricks from Tungsten Tailings

- Details

- Category: Tungsten Information

- Published on Wednesday, 08 August 2018 09:29

In China, a large amount of tungsten tailings and tungsten waste rock after hand picking has been produced in the mining and processing of tungsten ore. And they are generally dumped into and stored in the tailings ponds. For a long period, most mining businesses are committed to production of tungsten ore, the reclamation of tailings have rarely been noticed.

The Simple Separation of the Complex Wolframite and Scheelite Symbiotic Ore

- Details

- Category: Tungsten Information

- Published on Tuesday, 07 August 2018 23:29

The ratio of scheelite and wolframite is 1: 9~9: 1 in the co-occurrence ore. separation of scheelite from wolframite from complex polymetallic ores has always been a difficult task for mineral processing.

In view of this problem, some scholars have proposed a beneficiation method with good separation effect, high recovery, simple operation and low reagent cost for scheelite. The method is made up of the following steps in turn:

sales@chinatungsten.com

sales@chinatungsten.com