Tungsten Oxide Nanorod Regulation Method

- Details

- Category: Tungsten Information

- Published on Saturday, 28 April 2018 15:48

At present, the general method of preparing tungsten oxide is liquid phase method. In the process of preparing tungstic acid in liquid phase, the tungstic acid particles are automatically coalesced because of the unstable thermodynamics. In addition, the free water molecules on the surface of the particles form hydrogen bonds with the free hydroxyl groups, and then form a hydrogen chain with the water molecules on the surface of the adjacent particles to produce a bridging action.

Some scholars have proposed a method of adjusting the length of tungsten oxide nanorods by oxygen, with a surface functionalized carbon nanotube with a diameter of 2-200 nm and a layer of 1-30 layers as the carrier, tungsten metal salt as the tungsten source, the addition of hydrochloric acid in the carbon nanorod glycol suspension and tungsten metal salt system, and the principle of making the weak acid with strong acid to make tungstate granules. It directly forms on the surface of the carbon nanotubes and grows along the surface of the carbon nanotubes to form tungstate / carbon nanotube rod like composites, which mainly include the following steps:

(1) The 1-50 mg diameter of 2-200 nm and 1-30 layers of carbon nanotubes were soaked in strong acid (one or several mixtures in HCl, nitric acid, sulfuric acid), refluxing, filtering, drying, and then being placed in 10-500 mL ethylene glycol at 100-140°C. The ultrasonic dispersion of 8-24h. A uniform carbon nanotube glycol suspension was obtained.

(2) Tungsten metal salt is completely dissolved in solvent (deionized water, ethylene glycol or mixture of both), and a tungsten metal salt solution with a concentration of 0.01-0.5 mol /L is obtained.

(3) The carbon nanoscale glycol suspension is added to the tungsten metal salt solution and is mixed uniformly under the action of mechanical stirring (constant temperature magnetic agitator or ultrasonic oscillator), in which the molar ratio of tungsten metal salt and carbon nanotube is 1:1-40:1, and then added to them (using micro injector, drip tube or hydrochloric acid atomization, etc. The concentration of 1-20 mL was 5-12 mol/L hydrochloric acid, and the pH value of the solution was adjusted to 1-5; 5-48h was reflued under the constant temperature oil bath at 80-140°C, then vacuum filtration, washing and drying were carried out. The drying temperature was 100-150°C, and the drying time was 3-24h, and the tungstate / carbon nanotube rod like complex was obtained.

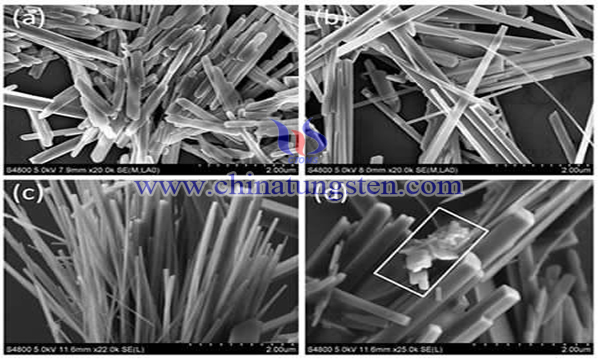

(4) The composite is spread in the corundum reaction boat and together with the corundum reaction boat together with the horizontal quartz reaction tube in a tubular resistance furnace. When the sample is roasted, different proportions of oxygen and nitrogen are put into the horizontal quartz reaction tube, the flow rate is 30-500 mL/min, and the oxygen content is 0-100% and the heat treatment temperature is at the temperature. At 400-800°C, the heat treatment time is 0.5-12h. When cooled to room temperature, the tungsten oxide nanorods with a length of 20-800nm can be obtained.

With carbon nanotubes as a template, tungstic acid / carbon nanotube nanorods were prepared by liquid phase method. After that, the tungstate / carbon nanotube nanorods were placed in the high temperature reaction zone of the tube furnace. In the process of dehydration of tungstate precursor and conversion of tungsten oxide into the tungsten oxide, the oxidation atmosphere was entered to make the carbon nanotubes burning and generating two oxygen. With the disappearance of carbon nanotubes and the disappearance of the carbon nanotubes, the tungstic acid nanorods break, which interferes with the growth of tungsten oxide along the surface of the tube bundle of carbon nanotubes. Therefore, the preparation of the process is simple and it is easy to popularize.

- Tungsten Oxide Manufacturer & Supplier, Chinatungsten Online: www.tungsten-oxide.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com