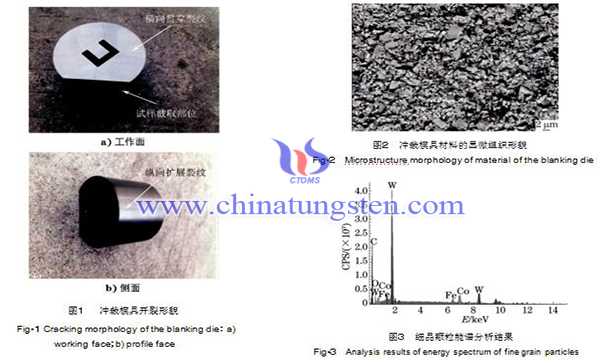

Cracking of YG8 Tungsten Carbide Blanking Die

- Details

- Category: Tungsten Information

- Published on Monday, 02 April 2018 20:35

YG8 tungsten carbide is composed of refractory WC hard phase and cobalt cemented phase and sintered by powder metallurgy. It has high hardness, high wear resistance, good strength and toughness of the material, and has a series of excellent properties, such as high temperature resistance, corrosion resistance, small expansion coefficient and so on.

The strength and toughness of this material remain basically unchanged even at the temperature of 500℃, and high hardness still remains at 1000℃. Because its service life is ten times or even dozens of times of ordinary alloy steel mold, YG8 tungsten carbide is widely used for making punching die and drawing die.

Due to the poor preservation of raw materials, a large number of brittle η phase and network cracks are produced in the material, resulting in a sharp decrease in the strength and toughness of the material. And the failure of the die to withstand the working stress in the service process occurs, resulting in cracking. The cracking initiates and expands rapidly at the U groove corner of the die, leading to the cracking of the die face.

The properties of tungsten carbide are affected by particle size, sintering condition and content of oxygen and carbon in powder. In the manufacturing process of cemented carbide, it is necessary to operate in accordance with the requirements of the specification, in order to avoid the oxidation of tungsten powder produced is η brittle phase. The tungsten carbide dies surface needs grinding, of which the grinding is several times that of the structural steel. And it is very easy to cause the grinding burn. Therefore, the grinding machine is required to have large power, high rigidity of the grinding wheel and fully cooling.

During the process of EDM, the surface of the die has a brittle and hard metamorphic layer and even a micro crack. Therefore, the pulse current of electrical machining must be reduced, and the surface metamorphic layer of the die must be reduced. Some scholars suggested installing protective inserts on the periphery of blanking dies, making hard alloy dies withstand greater impact load and extrusion load. Gap requirements are very strict for whether hot pressed or cold pressed. The amount of interference of the general hot pressing set is 0.08~0.10mm, the heating temperature of the set is 700~800℃, and the heating temperature of the tungsten carbide is about 300℃. After the hot-pressing assembly is completed, it is put into the 600℃ box furnace to keep 2h in order to eliminate the internal stress of the die material and improve the service life of the die.

- Tungsten Carbide Manufacturer & Supplier, Chinatungsten Online: tungsten-carbide.com.cn

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com