YG8 Tungsten Carbide Die: Structure

- Details

- Category: Tungsten Information

- Published on Monday, 09 April 2018 17:38

YG8 tungsten carbide has the characteristics of high melting point, high hardness, good toughness, super wear resistance, low coefficient of thermal expansion, long service life and so on. As a material of drawing and forming die, it becomes more and more popular.

But its high price has added a lot of obstacles to its popularization and application. In order to reduce the manufacturing cost and improve the service life of dies, the die structure with YG8 tungsten carbide ring set is often used. Some scholars have continuously explored and improved the structure of YG8 carbide die set.

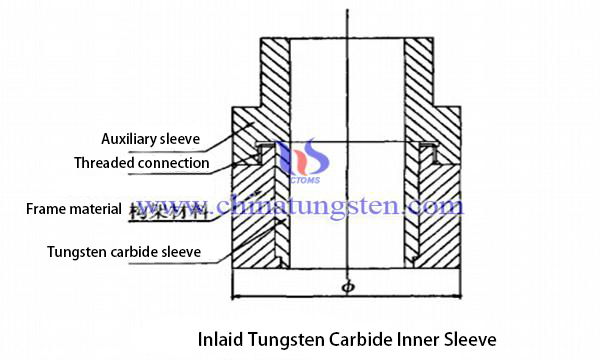

The inlaid structure of YG8 tungsten carbide solves the obvious shortcomings of traditional methods by using the method of using physical cold extrusion fixation, ensuring the safety and efficiency of production.

1, Design Improvement of Structure

For the tungsten carbide coat, using its outer surface as the working face, the inner hole of the hard alloy sleeve is grinded out of the concave table so that the frame material is threaded to fix the sleeve. For embedded tungsten carbide inner sleeve, the inner surface is used as the working face. The outer circle of the carbide sleeve is grinded out to make the frame material threaded and fixed with the sleeve.

2, Advantages of Improved Structural Design

During the processing, all processes are processed by cold working to avoid the influence of high temperature on the mold materials. The traditional manufacturing process, whether hot charging or copper welding, will more or less change the structure of frame material and YG8 material. In the manufacturing process, the structure of the frame and the sleeve are small, and the fine thread extrusion is adopted. The thread connection is added with the locking anaerobic adhesive, and the stability of the die is ensured in the process of use. It greatly reduces the time and cost of die maintenance and prolongs the service life.

The one pass rate of mould manufacturing is obviously improved. The qualified rate of finished products made by the improved tungsten carbide mold can reach over 95%, which also reduces manufacturing cost to some extent. The maintenance and replacement of moulds are convenient, while the cost of production is reduced. Especially in the trial production stage of new products, the product size is frequently altered, resulting in mold changes. The embedded YG8 alloy sleeve can be separated from the clamping tool for the frame, and the frame and the alloy sleeve can be selected according to the need, so as to reduce the cost of re manufacturing the mold.

3, Disadvantages of Improved Structural Design

The manufacturing cost of single mold increases slightly, but it is negligible compared with the rate of qualified manufacturing and the benefit of production.

Through the comparative analysis of the above die structure design, the improved mold structure has obvious superiority in processing and using effect. With more than 3 years of practice, some scholars have proved that the improved die structure is safe and stable in production and has created considerable benefits to the society, and is also deeply loved by many production departments and operating workers.

- Tungsten Carbide Manufacturer & Supplier, Chinatungsten Online: tungsten-carbide.com.cn

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com