Preparation Method of Tungsten-Based Tungsten Trioxide Nanofilm

- Details

- Category: Tungsten Information

- Published on Wednesday, 25 July 2018 18:33

In recent years, research on tungsten trioxide (WO3) nanofilm has attracted more and more attention. WO3 is an n-type semiconductor material with a narrow band gap (2.4-2.8eV), is capable of responding to visible light, and has similar characteristics to TiO2 photocatalyst, namely stable, non-toxic, photo-resistant, low-cost and low-priced. The potential of the belt is high and the photo-generated holes are highly oxidizing.

Preparing Tungsten-Zirconium Alloy with Arc Melting Process

- Details

- Category: Tungsten Information

- Published on Wednesday, 25 July 2018 18:24

Tungsten is a very important non-ferrous metal. It has the properties of high density and high hardness. It is commonly used in counterweight materials, shielding materials and military materials. Tungsten-zirconium alloy has a broad application prospect in the military field due to its strong resistance to corrosion.

Preparation of Tungsten Disulfide Transverse Heterojunction

- Details

- Category: Tungsten Information

- Published on Wednesday, 25 July 2018 18:09

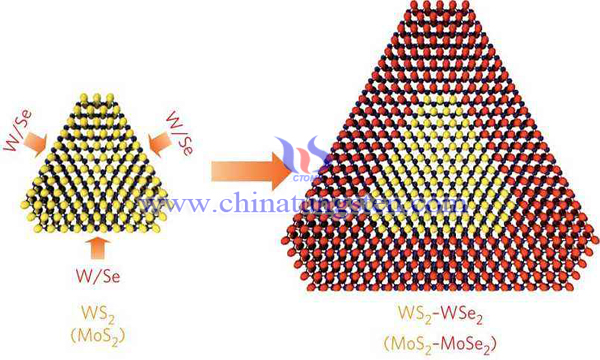

Heterojunctions have become an essential element of the modern semiconductor industry, and they play an important role in high-speed electronic devices and optoelectronic devices. Two-dimensional layered materials, including graphene and transition metal disulfide, can serve as a constituent unit of a heterostructure due to their unique electrical and optical properties.

Recovering Vanadium and Tungsten from Vanadium-Titanium-Based Waste Denitration Catalyst

- Details

- Category: Tungsten Information

- Published on Wednesday, 25 July 2018 17:54

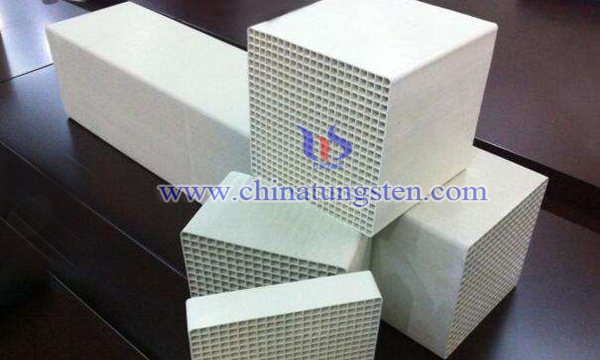

Nitrogen oxides (NOx) are recognized as one of the major sources of atmospheric pollution, including combustion fumes and automobile exhaust. Monolithic vanadium-titanium-based catalysts have been widely used for the removal of NOx from combustion fumes or automobile exhaust, and NOx is removed by selectively catalyzing the reduction of NOx by NH3 to N2. The catalyst uses TiO2 as a carrier (usually 80-90% of the total mass), V2O5 as an active component (1-2%), and WO3 as a co-catalyst (5-10%).

A New Dissolution Process for Ammonium Paratungstate / Tungsten Trioxide

- Details

- Category: Tungsten Information

- Published on Wednesday, 25 July 2018 10:35

At present, ammonium paratungstate can completely dissolve for 1~4 hours at a temperature of 120~160°C with high concentration of ammonia, some enterprises promote the decomposition of ammonium paratungstate and even through high temperature roasting to get tungsten oxide, then ammonium tungstate solution is dissolved in ammonia water, and some enterprises use sodium hydroxide and other strong alkali to dissolve ammonium paratungstate. The ammonium tungstate solution is regenerated from sodium tungstate solution, the process is complex and costly. Therefore, it is necessary to develop a new low-cost and simple dissolution process for ammonium paratungstate / tungsten trioxide.

Electric Hydrolysis of Tungsten Trioxide /Tungsten Oxide

- Details

- Category: Tungsten Information

- Published on Wednesday, 25 July 2018 10:06

Tungsten trioxide is an important type of N type semiconductor oxide. It is widely used in chemical sensors, photocatalysis, energy conversion system and other fields. When WO3 is used as negative material, its structure and volume will change greatly during charge / discharge process. It destroys the stability of electrode materials and eventually leads to the cyclic performance of the electrode. As a result, the actual capacity is often lower than the theoretical capacity.

New Technology to Solve the Defects of Tungsten Carbide Ceramics

- Details

- Category: Tungsten Information

- Published on Wednesday, 25 July 2018 09:43

Tungsten carbide ceramics are a kind of cermet with high hardness and good wear resistance. However, under traditional technological conditions, the cutting tool made of tungsten carbide ceramics has a short service life at high temperature and is difficult to be applied to high temperature conditions.

Ammonium Paratungstate Extraction from Refractory Tungsten Ore

- Details

- Category: Tungsten Information

- Published on Wednesday, 25 July 2018 09:33

After a variety of ore dressing methods have been obtained to a certain grade of tungsten concentrate, it will also produce tungsten fine slime or tungsten refractory materials about 6 to 10% of the total tungsten (WO3). This material is characterized by low grade of WO3, high content of major impurity elements such as Mo, Sn, P, As, Si and so on. It is polluted by a variety of mineral processing agents and it can not return to mineral processing and reprocessing. It is necessary to extract tungsten from these refractory tungsten ores by an effective smelting method, which is the only way to improve the utilization ratio of tungsten resources comprehensively.

Recycling Tungsten from Tungsten Catalyst

- Details

- Category: Tungsten Information

- Published on Tuesday, 24 July 2018 21:40

Tungsten catalyst has been widely used in various oxidation systems due to its excellent catalytic performance. In order to better control production cost and realize large-scale economic production with tungsten catalyst for oxidation reaction, at the same time, in order to save precious tungsten resources, avoid tungsten pollution in the environment and save environmental production, tungsten catalyst must be recycled and reused.

High Quality Tungsten Molybdenum Alloy Preparation by Multielement Doping

- Details

- Category: Tungsten Information

- Published on Tuesday, 24 July 2018 21:29

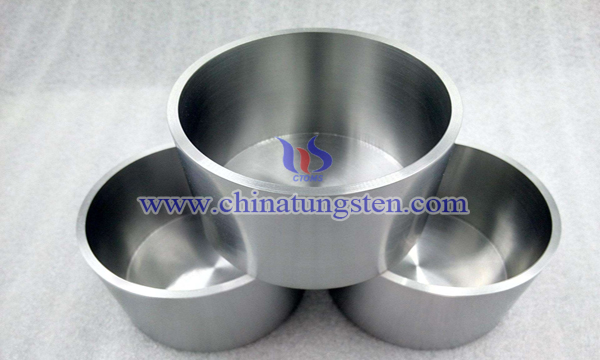

Tungsten and molybdenum alloys have excellent corrosion resistance to liquid zinc and are used to make agitators, pipes and container liners and other components in zinc smelting industry. It can be used as a high temperature component in rocket and missile, the filament of the electron tube, parts and other high temperature materials for the corresponding high temperature conditions.

sales@chinatungsten.com

sales@chinatungsten.com