Bismuth Tungstate Silver Composite Photocatalyst

- Details

- Category: Tungsten Information

- Published on Friday, 30 March 2018 23:43

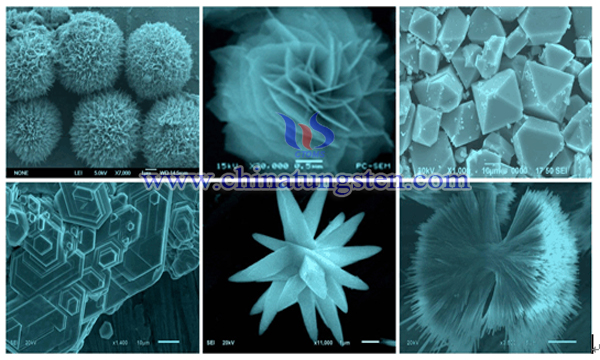

The traditional semiconductor photocatalyst TiO2, ZnO and other large band gap, can only absorb UV light, the low utilization rate of the light of the sun, has seriously hindered the practical application of photocatalytic technology, bismuth tungstate is a new type of catalyst with visible light, the band gap is small, light absorption ability, easy modification, and it gradually become the traditional photocatalyst product upgrades.

The scholar discloses bismuth tungstate silver composite photocatalyst supported silver nanoparticles, the preparation process for the bismuth nitrate and sodium tungstate were dissolved in ethylene glycol, adding silver nitrate to the mixture of both the bismuth tungstate after hydrothermal reaction to obtain the final product loaded with silver.

The steps of preparing bismuth tungstate composite photocatalyst by hydrothermal synthesis are as follows:

1. According to the quality of bismuth nitrate and nitric acid ratio of 3~5 to 1 the proportion of the added bismuth nitrate concentration is 1 ~ 4mol/L in nitrate solution mixing at least 30min, obtained bismuth nitrate solution, and then according to the quality between sodium tungstate and deionized water as the ratio of 30~50: 1 ratio of sodium tungstate into deionized water and stirring uniform, get sodium tungstate solution.

2.The polyvinylpyrrolidone (PVP) is added to the sodium tungstate solution and mixed uniformly to obtain a mixed solution. The yttrium nitrate solution is then added to the mixed solution to obtain a precursor solution. Subsequently, the precursor solution is placed in a closed state at a temperature. For 160 ~ 180 ℃ under heat for 20 ~ 24h, then wait for the natural cooling to room temperature, the centrifugation, washing and drying to obtain tungstate powder;

3.According to the ratio of the mass ratio of silver nitrate to lanthanum tungstate is 0.01-0.03:1, the lanthanum tungstate powder is added into a silver nitrate solution with a concentration of 0.01-0.1 mol/L and stirred uniformly to obtain an intermediate product. The intermediate product is dried and then ground into a powder. The powdery intermediate product is calcined at 200-500℃ for 1-4 hours to prepare a bismuth tungstate silver composite catalyst modified by silver.

The silver modified bismuth tungstate composite photocatalyst was degraded by visible photocatalytic degradation in water polluted by organic or heavy metal ions. Studies have shown that yttrium silver tungstate composite photocatalysts can effectively treat phenol, herbicides 2,4-D, methylene blue, rhodamine B, and methyl orange; and contaminated wastewater containing heavy metal ions of chromium, lead, or mercury ions.

- Tungsten Oxide Manufacturer & Supplier, Chinatungsten Online: www.tungsten-oxide.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com