Characteristics of Tungsten Carbide Die Fittings

- Details

- Category: Tungsten Information

- Published on Friday, 30 March 2018 21:05

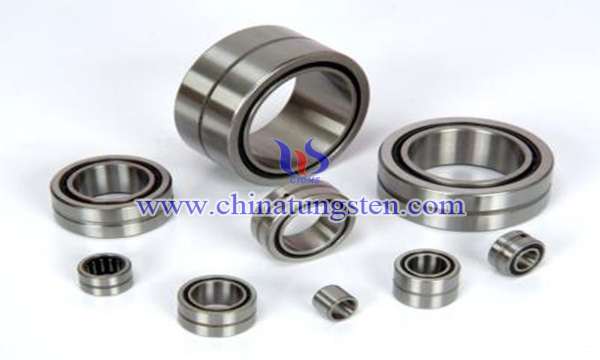

Generally speaking, high quality tungsten carbide die should have the following properties: high strength, good wear resistance, enough thermal stability and excellent technicality. As the application of die fittings is more and more extensive, the quality requirements are becoming higher and higher, maximizing the use performance of die parts. So, what are the characteristics of the tungsten carbide die fittings?

1, Abrasion Performance

When the blank is plastic deformed in the mold cavity, it flows and slides along the surface of the cavity, resulting in severe friction between the surface and the billet, resulting in failure of the die due to wear. So, the wear resistance of the material is one of the most basic and important properties of the tungsten carbide die.

Hardness is the main factor affecting the wear resistance. In general, the higher the hardness of the mold parts is, the smaller the wear and the better the wear resistance will be. Additionally, the wear resistance is also related to the type, quantity, shape, size and distribution of carbides in the material.

2, Obdurability

Most of the working conditions of the die are very bad, and some often bear large impact load, which may even lead to brittle fracture. In order to prevent the die parts from working suddenly and brittle, the mold parts should have high strength and toughness.

3, Elevated Temperature Property

When the working temperature of the mold parts is high, their hardness and strength will be reduced, resulting in the failure of early wear or plastic deformation. Therefore, the mold material should have high anti tempering stability, so as to ensure the high hardness and strength of tungsten carbide die fittings at working temperature.

4, Behavior of Fatigue Fracture

In the working process, fatigue fracture of tungsten carbide die fittings often can be seen under the long-term action of cyclic stress. Its form has small energy multiple impact fatigue fracture, tensile fatigue fracture contact fatigue fracture and bending fatigue fracture. Its behavior of fatigue fracture depends on the strength, toughness, hardness, and the content of inclusions in the material.

- Tungsten Carbide Manufacturer & Supplier, Chinatungsten Online: tungsten-carbide.com.cn

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com