Precision Compaction of Tungsten Carbide Mold Powder

- Details

- Category: Tungsten Information

- Published on Friday, 06 July 2018 16:57

Tungsten Carbide Dies for Cold Heading

- Details

- Category: Tungsten Information

- Published on Friday, 06 July 2018 16:54

The Manufacturing Method of Tungsten Yttrium Electrode

- Details

- Category: Tungsten Information

- Published on Wednesday, 04 July 2018 23:08

When the tungsten tungsten electrode is welded, the arc beam is slender and has a high degree of compression, especially in the medium and high current penetration. It is mainly used in the military and aerospace industries. Tungsten yttrium electrode has the characteristics of long life and good arc starting performance, and has broad application prospects.

Nuclear Application of Tungsten Tantalum Alloy

- Details

- Category: Tungsten Information

- Published on Wednesday, 04 July 2018 23:00

Due to its high density, high melting point, corrosion resistance, and weldability, tungsten-rhenium alloy materials make it a plasma-facing material in nuclear fusion reactors, and it is a very important material for plasma materials in nuclear fusion reactors. It is related to the stability of the plasma in the reactor, the first wall structural materials and components from plasma bombardment and other issues.

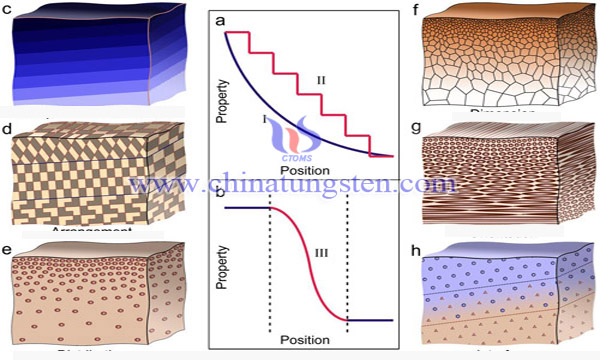

Tungsten Copper Gradient Materials Preparation by Thermochemical Method

- Details

- Category: Tungsten Information

- Published on Tuesday, 03 July 2018 10:56

Tungsten copper alloy is a pseudo alloy consisting of insoluble tungsten and copper. The alloy has the advantages of high melting point, corrosion resistance, low expansion coefficient, wear resistance and so on. At the same time, it has the advantages of high conductivity and thermal conductivity, good plasticity and easy processing of copper, but in many cases, it is required to tolerate high temperature on one side of the material. The other side is connected to the copper or copper alloy with good thermal conductivity. Because the physical properties of tungsten and copper are quite different, the single component tungsten copper alloy is difficult to relieve the thermal stress inside and on the interface, and the functionally graded material can solve this problem better.

Sodium Tungstate Defluorination with Ion Exchange Method

- Details

- Category: Tungsten Information

- Published on Tuesday, 03 July 2018 10:34

Alkali process is widely used in tungsten smelting in China. In the process of alkali decomposition of tungsten concentrates, a small amount of CaF2 and NaOH react with sodium fluoride into sodium wolframidotungstic acid solution. Due to the lack of low cost and effective defluorination technology, the cost of sodium fluoride purification treatment in China's tungsten smelting enterprises is higher.

Anti Bending Tungsten Molybdenum Composite Board Process

- Details

- Category: Tungsten Information

- Published on Tuesday, 03 July 2018 10:22

Molybdenum and molybdenum alloy composite plates are widely used as boat or cushion material for the sintering industry of electronic ceramic substrate because of their advantages of high melting point, good heat resistance, low evaporation pressure, good thermal conductivity and small coefficient of thermal expansion.

A Brief Analysis of the Preparation Process of High Purity Ammonium Paratungstate

- Details

- Category: Tungsten Information

- Published on Monday, 02 July 2018 22:18

Tungsten is a very important strategic resource. With the development of the following products, tungsten wire, tungsten powder, tungsten strip and other high-end cemented carbide require continuous improvement of ammonium para tungstate. The existing national standard zero grade ammonium para tungstate can not meet the requirements of high end cemented carbide, which not only deals with the impurities and physical properties of ammonium para tungstate. A certain requirement can be put forward, and the enterprises that produce some high-end products have put forward special strict requirements for individual impurity elements. Therefore, the high purity tungsten powder is more popular in the market.

Preparation of Irregular Special-Shaped Parts with Pure Tungsten Powder

- Details

- Category: Tungsten Information

- Published on Monday, 02 July 2018 22:07

With the development of electronic industry, the demand for pure tungsten special-shaped parts is increasing. Tungsten shaped parts are of great importance in aerospace, military industry and nuclear industry. Especially in the field of semiconductor technology, Bluetooth, Wi-Fi, 3G and other applications are booming. The ion implantation machine is the main equipment for the production of semiconductor crystal garden.

Waste Tungsten Recycle Sodium Perchlorotungstate by Ion Exchange Method

- Details

- Category: Tungsten Information

- Published on Monday, 02 July 2018 21:54

Industrial wastes containing heavy metals such as copper, nickel, cobalt, manganese, tungsten, and other heavy metals are treated by proper methods, and the valuable components of the industrial waste can be recycled, the harmless and resource utilization of industrial waste can be realized. At present, the method of metal recycling for such industrial wastes is usually used by alkali leaching, using sodium hydroxide or sodium carbonate as leach agents. The tungsten is leached under normal pressure or pressure condition, and tungsten is separated from other metals, and the tungstate solution is obtained by ion exchange and enrichment in the next step, the alkali leaching residue is then soaked in acid. Removal of impurities, separation and purification of copper, nickel, cobalt and manganese products.

sales@chinatungsten.com

sales@chinatungsten.com