WC-Co Tungsten Carbide: η Phase

- Details

- Category: Tungsten Information

- Published on Wednesday, 21 March 2018 14:44

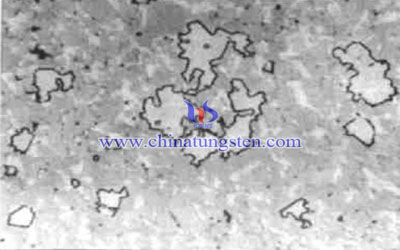

Generally speaking, the η phase of WC-Co tungsten carbide is harmful, which will reduce the physical and mechanical properties of alloys. The ratio of [W]/[C] in the γ phase exceeds the stability value, resulting the nucleation of η phase. With the increase of sintering temperature, the η phase will grow up, which will stop when reach thermodynamic equilibrium.

Nucleation Mechanism of η Phase

The diffusion of C atoms in the γ phase of WC-Co tungsten carbide is fast, while the diffusion rate of W is very slow. As a result, when WC dissolves in the form of a single atom, the C atoms can escape from the alloy from the γ phase. In γ phase of three-phase WC+γ+η1 tungsten carbide, the consistence of W solute in the γ phase is always more than that of C solute. For example, at a room temperature, the average value of [W]/[C] in solid state alloy is stable at 2.84.

At high temperature, such as sintering temperature at 1350-1500℃, when the alloy is in equilibrium, the concentration of W and C solute in the gamma phase is stable at corresponding temperature. Once the loss amount of C concentration is too much, the [W]/[C] value exceeds its stable value, then generating η phase.

The η phase crystal billet should give priority to a gamma phase boundary along the WC and attached to the surface of WC crystalline nucleation as heterogeneous nucleation core. The surface and edges of incomplete WC grains is high surface energy site and is usually filled (i.e. phase Ya present room temperature solid alloy in WC grains on the surface of the "cobalt tumor") is more conducive to the nucleation phase. The actual reaction formula is as follows:

3Co+W=Co3W(1)

2Co3+4W+C=Co6W6C(2)

CoW6C+C=2Co3W3C(3)

During sintering, it is mainly from the dissolution of WC to the γ phase. With the deficient of carbon alloys (such as WC+W2C+W+Co components), it is also derived from the dissolution of W and W2C into the gamma phase. Therefore, it is believed that in the heating process, Co3W and Co6W6C successively generate, and then the η phase generates at high temperature.

Growth Mechanism of η Phase

Because the formation of η phase is at the price of the consumption of W and C of γ, phase solute in the reaction (1) is also associated with C from the alloy diffusion, leading to the decrease of W and C concentrations. WC grains adjacent to γ phase will remain of dissolved phase and grain growth, the W and C saturation value of the temperature (also from part of C atoms from the alloy). Once the alloy reach thermodynamic equilibrium state, then stop phase nucleation.

- Tungsten Carbide Manufacturer & Supplier, Chinatungsten Online: tungsten-carbide.com.cn

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com