How to Improve the Quality of Regenerated Tungsten

- Details

- Category: Tungsten Information

- Published on Sunday, 17 June 2018 11:13

In view of the shortage of raw tungsten resources, it is of great significance to reuse the waste hard alloy products and reuse it after recycling, and it is very important to make full use of the protection resources. In the United States, 35% of tungsten products are derived from recycled tungsten.

How to Recycle Bismuth Ore from Tungsten Tailings

- Details

- Category: Tungsten Information

- Published on Sunday, 17 June 2018 11:01

The content of bismuth in the earth's crust is only about 10‑6%, which is symbiosis with other metal minerals such as tungsten and molybdenum. Generally, bismuth is recycled from the by-products of other main metal refining processes, such as the exploitation of tungsten ore and the production of bismuth ore.

Zero Pollution Preparation of Ammonium Para Tungstate

- Details

- Category: Tungsten Information

- Published on Sunday, 17 June 2018 10:52

Ammonium para tungstate is prepared mainly by caustic soda or soda decomposition, and pure ammonium tungstate solution is obtained. Then APT products are obtained by evaporation crystallization. No matter which method is adopted, the result is large water consumption and large amount of waste water is needed.

Tungsten Tailings Recycling

- Details

- Category: Tungsten Information

- Published on Thursday, 07 June 2018 17:18

The traditional tungsten tailings recovery mostly uses a mineral processing method to recycle an element in the tailings, and other valuable metals can not be recycled. In order to improve the benefit of recycling, a large mine adopts a combination of gravity separation and flotation, and a reasonable control of the pH value of the pulp. By controlling the ratio of the flotation agents at various stages, the low grade valuable elements in the tungsten tailings are recycled, and the methods of recycling the three kinds of metal elements, tin and molybdenum are mainly used. The whole process of recycling is divided into four stages.

High Efficiency Separation of Tungsten and Molybdenum from Special Resin

- Details

- Category: Tungsten Information

- Published on Thursday, 07 June 2018 17:12

In the classical process, the removal of molybdenum in ammonium tungstate solution is a method of combining selective precipitation with ion exchange. By sulfurizing the ammonium tungstate solution in advance, Mo and S2- in ammonium tungstate solution are formed into thiomolybdenum root, most of which are precipitated and removed with the added copper salts, and the unprecipitated thiomolybdate root is passed through. The exchange column is further purified by resin adsorption.

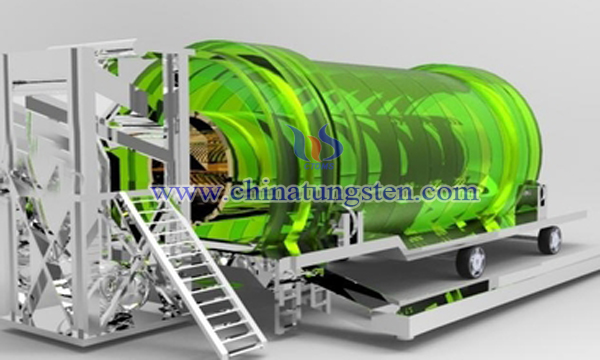

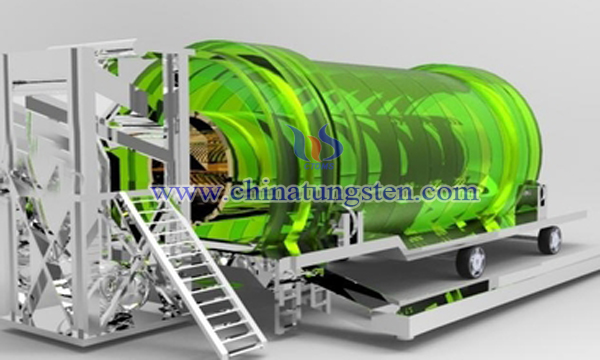

Roasting Tungsten Mineral Raw Material Flue Gas Spray Wastewater Treatment Process

- Details

- Category: Tungsten Information

- Published on Thursday, 07 June 2018 17:04

During the treatment of ammonium para tungstate, the high temperature oxidation roasting of tungsten mineral materials was carried out in the rotary kiln, and the tungsten mineral raw materials were derived from the low temperature end of the kiln tail and out of the kiln head after the high temperature section. The fuel and air enter and burn after the kiln head, and the flue gas is discharged from the low temperature end of the kiln. The flotation reagents and other organic substances contained in tungsten mineral raw materials are partly removed at high temperature and partly evaporate in the low temperature section of the kiln bottom and enter the roasting flue gas. Tungsten minerals usually contain arsenic containing minerals. Under roasting conditions, some forms of arsenic, such as As2S3 and As2S5, will be roasted in the form of gaseous state and will also enter the roasted flue gas. Dust and sulfur and phosphorus can also enter into the roasting flue gas.

Argon Arc Welding Rare Earth Tungsten Electrode

- Details

- Category: Tungsten Information

- Published on Thursday, 07 June 2018 16:54

Argon arc welding is an arc welding method using argon as a protective gas. Argon gas is used around the arc to form a continuous closed air flow to protect the arc and pool.

The Manufacturing Method of Lanthanum Tungsten Electrode

- Details

- Category: Tungsten Information

- Published on Thursday, 07 June 2018 16:48

Tungsten electrode material is one of the key materials in argon arc welding technology. Cerium tungsten electrodes have been developed to replace radioactive thorium tungsten electrodes in the field of TIG and PLASMA technology.

Tin Removal by Magnesium Salt Precipitation Method

- Details

- Category: Tungsten Information

- Published on Thursday, 07 June 2018 16:40

Due to the increasing shortage of tungsten resources and more and more high impurities and low grade ores entering the tungsten smelting process, the content of impurities such as silicon, phosphorus, arsenic and tin in the sodium tungstate solution obtained by tungsten is becoming higher and higher. In order to produce tungsten products such as high purity ammonium para tungstate (APT) and tungsten oxide, sodium tungstate solution must be clean.

Purification of Ammonium Para Tungstate Solution after Ion Exchange by Molybdenum Removal

- Details

- Category: Tungsten Information

- Published on Thursday, 07 June 2018 16:28

Before crystallization of ammonium para tungstate (APT), it is necessary to further remove molybdenum from the crystallization process of APT to obtain a more pure APT crystal product. The impurity removal rate in the crystallization process is directly related to the crystallization rate of APT. With the increase of the crystallization rate of APT, the precipitation rate of impurity increases rapidly. For the same concentration solution, when the crystallization rate of tungsten is increased from 60% to 80%, the crystallization rate of molybdenum will be increased by nearly 3 times. It is difficult to break through 80% of the crystallization rate.

sales@chinatungsten.com

sales@chinatungsten.com