Preparation for Cesium Tungsten Bronze by Resin Exchange and Sol Gel Method

- Details

- Category: Tungsten Information

- Published on Friday, 01 June 2018 16:10

Energy conservation is a problem that must be considered in the sustainable development of every country's economy. In the energy consumption of many countries, building energy consumption accounts for about 30 ~ 40% of the national energy consumption, while the energy consumed through glass doors and windows accounts for more than 50% of the energy consumption of the building. If the transmission of near infrared light is reduced, the heat shielding effect will be greatly improved. Transparent heat insulation coating and transparent heat insulation film have bright prospects for economic, convenient use and good insulation effect.

Bismuth Tungstate / Polyaniline Composite Photocatalyst

- Details

- Category: Tungsten Information

- Published on Friday, 01 June 2018 15:57

The modification methods of bismuth tungstate can be used in various ways. Researchers have provided a method for the preparation of bismuth / polyaniline composite photocatalyst with a simple process and excellent product performance. It is said that the composite photocatalyst has a good effect on the treatment of methylene blue in sewage.

Bismuth Tungstate / Silver Composite Photocatalyst

- Details

- Category: Tungsten Information

- Published on Friday, 01 June 2018 15:43

With the rapid development of science and technology, many new desulphurization technologies have been developed. Catalytic oxidation desulfurization is a new desulfurization technology. Catalytic oxidation desulfurization has a wide range of applications, the process does not consume hydrogen, and is easy to implement. The catalyst plays a very important role.

New Tungsten Carbide Stirring Carbon Equipment

- Details

- Category: Tungsten Information

- Published on Thursday, 31 May 2018 21:24

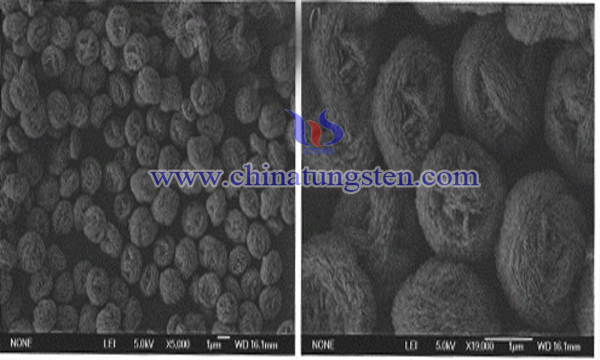

The traditional coarse grain tungsten carbide powder is produced by using the coarse tungsten powder reduced by Li+ or Na+, and rolling ball milling in the common carburizing device, and then heating in the ordinary carbon tube for high temperature (1800 to 2000 degrees C) for a long time carbonization.

The Processing Method of Tungsten Cerium Alloy Wire

- Details

- Category: Tungsten Information

- Published on Thursday, 31 May 2018 21:14

Adding a certain amount of rare earth elements in tungsten can change the properties of tungsten wire, such as adding cerium or thorium in tungsten can improve the electronic emission and ablative ability of the tungsten, and improve the processing properties of tungsten. The tungsten alloy wire and products produced by these characteristics are mainly used for electron tube hot wire, argon arc welding electrode and pulse tube heating wire.

Wheel Shaped Three Dimensional Hierarchical Structure Bismuth Tungstate

- Details

- Category: Tungsten Information

- Published on Wednesday, 30 May 2018 17:18

The key of photocatalytic technology is the photocatalyst. Bismuth tungstate as a new type of bismuth series of new photocatalyst. It is a multicomponent compound with layered structure. The lamellar formation is formed by the common angle of the WO6 eight sides, and a layer of [Bi2O2]2+ is distributed between layers. Bi2WO6 is a typical bismuth series photocatalyst. It exhibits excellent visible light photocatalytic activity in environmental pollution control and solar energy conversion. Bi2WO6 has high catalytic activity under visible light irradiation, which can cleavage aquatic O2 and degrade organic matter.

Copper / Bismuth Tungstate Composite Photocatalyst

- Details

- Category: Tungsten Information

- Published on Wednesday, 30 May 2018 17:04

Bismuth tungstate (Bi2WO6) is the most simple structure of Aurivillius type oxide. Its Bi6s orbit and O2p orbit are hybridized to form the valence band. The W5d orbit forms a guide band, and its band gap is narrower (about 2.7eV). It can absorb some visible light and be excited. Therefore, the Bi2WO6 photocatalytic material is in the field of environmental purification and new energy development. Potential application value.

Nanoscale Bismuth Tungstate Modified by Carbon Quantum Dots

- Details

- Category: Tungsten Information

- Published on Wednesday, 30 May 2018 16:44

With the development of nanomaterials technology, semiconductor photocatalysis technology has broad prospects for development. In particular, the development of visible light responsive semiconductor photocatalytic materials further promotes the application of semiconductor photocatalysis technology in the field of environmental remediation.

The Algae Pollution Treatment by Bismuth Tungstate Porous Material

- Details

- Category: Tungsten Information

- Published on Wednesday, 30 May 2018 16:32

A large number of domestic sewage and industrial waste water are discharged into rivers and lakes, resulting in eutrophication of water bodies, affecting the safety of water and living environment. The algae outbreak will cause the oxygen depletion in the water to lead to the death of the fish. The toxins released by some algae will poison the organisms. We should deal with the algae pollution quickly and effectively. It is an urgent need to control the water pollution.

Bismuth Tungstate Photocatalysis for Marine Oil Sewage

- Details

- Category: Tungsten Information

- Published on Wednesday, 30 May 2018 16:00

With the development of shipping industry, marine and river water pollution caused by ships is becoming more and more serious. Some researchers have proposed a scheme of photocatalytic treatment of ship oil sewage by pre separation + fine filtration + deep oxidation.

sales@chinatungsten.com

sales@chinatungsten.com