Tungsten Billet Process Improvement

- Details

- Category: Tungsten Information

- Published on Thursday, 08 March 2018 16:16

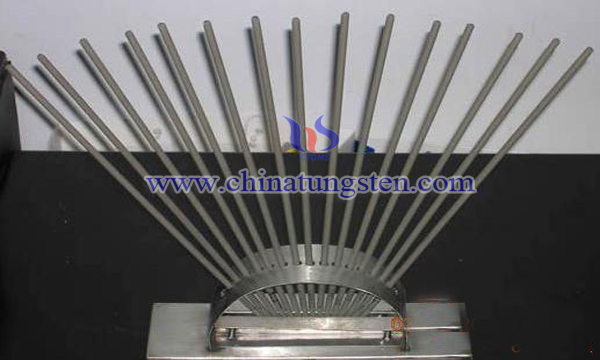

Tungsten billet mainly refers to pure tungsten, thorium tungsten, cerium tungsten, lanthanum tungsten, yttrium tungsten, zirconium tungsten, ternary composite (lanthanum, yttrium, cerium) and quaternary complex (lanthanum, yttrium, cerium, zirconium), is the production of tungsten electrodes and other raw materials rod.

Traditional powder metallurgy method of making tungsten billet, and then through the drawing process to manufacture tungsten filament. The existing process sequence for manufacturing tungsten billets is: doping, reduction, preparation of tungsten powder, pressing, pre-sintering, two vertical melting tungsten billets. This method needs more equipment and auxiliary materials, the process flow is extended, and the control difficulty is increased. The tungsten powder made in this way has more residual impurities, and it is necessary to reduce the effect on the quality of the material.

As for the shortcomings of the traditional methods, some scholars have improved the traditional technology.

1. Preparation of tungsten powder, making tungsten-based compound additives; the following raw materials in parts by weight preparation:

83 to 86% of WO3, 3 to 5% of K, 0.0004 to 0.001% of Al, 0.0003 to 0.001% of Mo,

2. Filtration: the aqueous solution of this additive was filtered to prepare a translucent solution;

3.Preparation: a solid liquid mixture is made, and the solid and liquid mixture is heated to 80~100 ℃, the pH value is 2~4, then the additive solution is added, and the mixture is stirred at the same time.

4.Drying: in the drying oven warming to 80 ~ 100 ℃, time 4 - 6 hours, into a dry powder;

5.Preparation of tungsten powder: temperature 85 ~ 900 ℃, time 1 hour, in a hydrogen atmosphere to obtain tungsten powder;

6.Pressing: The tungsten powder is placed in a mold and pressed into a tungsten billet at a pressure of 1200 to 1300 Kg/cm through a four-column hydraulic press;

7.Sintering: pre-sintering with a temperature of 1000 ~ 1200 ℃ 30 to 50 minutes;

8.Fused tungsten billet: With a conventional vertical melting furnace, the current from 4400 to 4700A is vertically melted for 40 to 45 minutes, and the finished tungsten billet is cooled.

Compared with traditional methods, this method greatly reduces the process flow, improves efficiency, saves cost, and reduces the content of harmful impurities and improves the quality of products. The machinable plasticity of the prepared billet is especially good, and the high temperature performance is easily controlled and stable.

- Tungsten Manufacturer & Supplier, Chinatungsten Online: www.chinatungsten.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com