Tungsten Ore Reelection Omnipotent Rocking Bed

- Details

- Category: Tungsten Information

- Published on Sunday, 17 June 2018 17:31

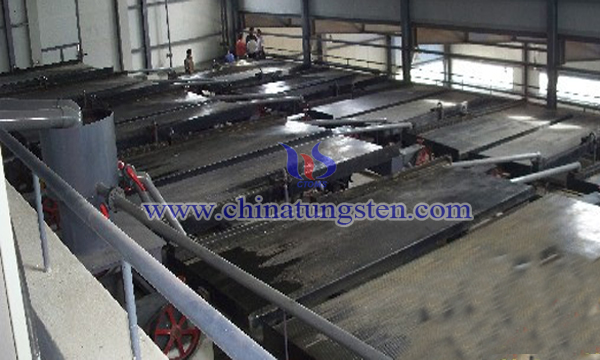

The table is commonly used in separation of fine ore dressing equipment, processing of metal ore can tick size in the 3 - 0.019 mm particles. After more than 100 years of development, the performance of ore dressing rocking bed has been perfected, mainly around the target of high efficiency and low space occupancy rate, and great progress has been made.

There is an all-around rocking bed with high, medium and low grade tungsten ores, which includes a power device, a transmission device, a bed surface of a rocker bed, a feed water feeder and a machine seat. The power device is connected with the transmission device, the transmission device is connected with the bed surface of the rocker bed, the bed surface of the rocking bed is connected with the water supply device, the seat and the shake are rocking. The bed surface is fixed.

The design framework of a tungsten ore reelection omnipotent rocking bed: the bed consists of a coarse selection area, a middle selection area, a selected area and a movable bed strip placement area. The coarse selection is higher than the middle selection area, the selected area and the movable bed strip placement area, and forms a convex area. The bed surface of the rocking bed is rectangular and the bed surface of the rocking bed is inclined along the diagonal line. The feed water feeding device is composed of a feed trough, a feeding chute, a feeding pipe, a first water supply pipe, a water supply tank, a second water supply pipe and a water supply chute.

The working principle of the new omnipotent rocking bed is that the rocking bed belongs to the gravity concentrating equipment, which is developed by the plane chute, and then is formed by its asymmetrical reciprocating movement. The bed is mainly composed of three parts: bed surface, machine seat and transmission mechanism. The bed has a variety of shape, mainly with three kinds of rectangular, trapezoid and rhombus. The bed surface is tilted. The bed is disposed with a feeding and water supply device; the bed is arranged with multiple beds. The bed is mainly arranged on the bed surface; the whole bed is made of the machine base. The transmission device is installed at one end of the bed surface, and the driving device makes the bed of the shaking table have the quick return characteristic, and realizes the separation of the ore particles.

The tungsten ore pulp is extracted from the pipe to the feeder, and the flow velocity of the first water pipe is adjusted according to the concentration of the pulp. The tungsten mine paddle fluid flows through the slots to the coarse selection, and through the grooves formed by the first bed strip to realize the separation. The tungsten ore particles selected by the coarse selection are flowing longitudinally in the grooves to flow to the selected area; through coarse selection. The selected tungsten ore particles are flowing laterally in the grooves to flow to the middle selection, and the tungsten ore particles are sorted by the staircase middle selection; the tungsten ore particles flowing to the selected area are placed through the movable bed strip, from second water supply pipes to the water trough, and the water trough is released to the water trough to achieve the re separation of the tungsten ore particles; finally, the selection of the tungsten ore particles is achieved. A high grade tungsten ore is obtained on one side of the area, and medium grade tungsten ore is obtained on one side of the middle electoral district, which intersects the selected area with the selected area, that is, the tailings of the trough are obtained, that is, the low grade tungsten ore.

- Tungsten Manufacturer & Supplier, Chinatungsten Online: www.chinatungsten.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com