γ Phase of WC-Co Tungsten Carbide

- Details

- Category: Tungsten Information

- Published on Sunday, 11 March 2018 10:57

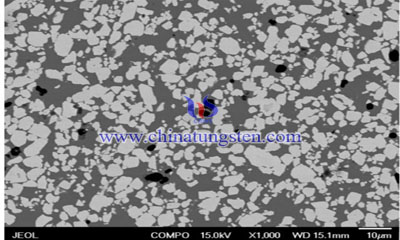

WC-Co tungsten carbide is the most widely used type of tungsten carbide. In industry, it is usually alloyed by powder metallurgy sintering such as low-pressure sintering. In the liquid process of phase sintering, WC is partially dissolved in cobalt, forming a Co-W-C solid solution based on Co. The solid solution phase is γ phase. The existence of γ phase makes the grain of WC rearranged and regrown, which is beneficial to the homogenization of grain.

The γ phase in the tungsten carbide is composed of γ phase grains separated by grain boundaries and phase domains that are distributed in homogeneously in the matrix. Both γ grain and γ crystal domain are equiaxed or near equiaxial. With the increase of the content of Co in the tungsten carbide, the volume fraction of the γ crystal domain also increases.

Compared with the WC-Co coarse grain alloy, the size of the gamma crystal domain in the fine grain alloy is larger and the volume fraction is larger. Primary facial heart cube (fcc) formatted at the eutectic temperature consistent with γ grain. The γ crystal domain is the residual FCC gamma that has not changed during the cooling of the alloy. The matrix is mainly transformed by diffusion. The product is densely arranged six party HCP gamma phase. With the increase of cooling rate, the size of the gamma crystal domain is gradually refined, the distribution is more uniform, and the volume fraction is also higher.

- Tungsten Carbide Manufacturer & Supplier, Chinatungsten Online: tungsten-carbide.com.cn

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com