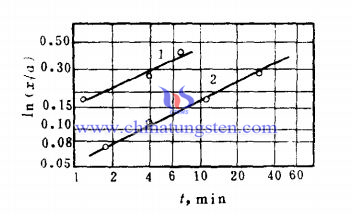

Sintering: Evaporation - Condensation

- Details

- Category: Tungsten Information

- Published on Sunday, 25 February 2018 18:21

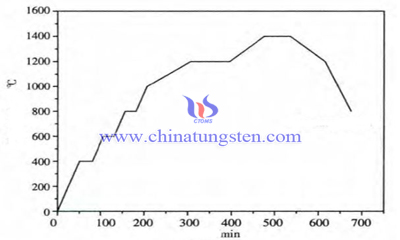

Effect of Heating Rate on Sintering Shrinkage

- Details

- Category: Tungsten Information

- Published on Sunday, 25 February 2018 18:17

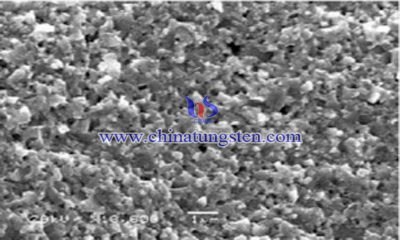

Effect of Grain Size on Sintering Densification

- Details

- Category: Tungsten Information

- Published on Sunday, 25 February 2018 18:14

Tungsten Carbide Direct Reduction and Carbonization Technology

- Details

- Category: Tungsten Information

- Published on Sunday, 25 February 2018 16:14

The ultrafine cemented carbide made of ultrafine tungsten carbide powder has the characteristics of high strength and high hardness. It effectively solves the contradiction between hardness and strength of traditional cemented carbide, widely used in the production of integrated circuit board micro drill, dot matrix printer print needle, precision mould, tool, woodworking tools, medical drill etc..

Preparation of Composite Photocatalyst with Copper Doped Violet Tungsten Oxide

- Details

- Category: Tungsten Information

- Published on Sunday, 25 February 2018 15:14

Tungsten catalyst in a large number of materials, with special surface structure of violet tungsten oxide, oxygen defect structure of high chemical activity and high concentration, and in the ultraviolet has a high degree of absorption, at the same time, research shows that copper as doping elements can improve the catalyst in the visible light response range. Therefore, the selection of copper doped violet tungsten as a photocatalytic material has a good application prospect.

Preparation of High Purity Ammonium Paratungstate

- Details

- Category: Tungsten Information

- Published on Saturday, 24 February 2018 21:24

The production of APT in China is mainly ion exchange and extraction. The quality of APT products produced by the two processes is generally the national standard zero grade products. The rest are the first grade or unqualified products of the national standard, and the disqualified products can only be sold at a low price, which not only directly affects the production efficiency of the enterprises, but also affects the quality of the subsequent tungsten deep processing products.

Preparation of Ultra Coarse Tungsten Carbide Powder in Cemented Carbide

- Details

- Category: Tungsten Information

- Published on Saturday, 24 February 2018 16:27

With the continuous development of the hard alloy industry, the requirements of tungsten carbide powder for its raw materials are becoming higher and higher. In China, the demand for hard alloy tools for rock breaking in the mountains is great, and the super coarse cemented carbide has strict requirements for the grain size of WC powder.

Tungsten Oxide Photocatalytic Ability to Improve

- Details

- Category: Tungsten Information

- Published on Saturday, 24 February 2018 14:52

In the development of photocatalysts, tungsten oxide as a stable, band structure suitable material can be modified to obtain a visible light response of high activity photocatalyst. Due to the lower valence band position of tungsten oxide, the forbidden band width is variable, it has excellent photoelectric properties, UV - visible light catalysis and other characteristics, so it can replace the old catalyst.

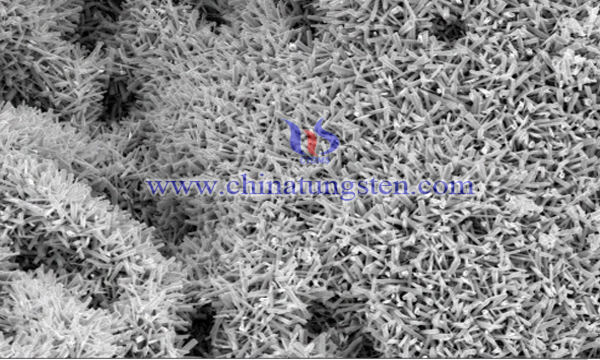

Tungsten Oxide Nano Flower Synthesis Step

- Details

- Category: Tungsten Information

- Published on Saturday, 24 February 2018 14:48

As a new type of tungsten oxide structure, tungsten oxide nano flower has its own unique advantages in performance. The synthesis method of tungsten oxide nano flower is mainly based on the seed planting method, the synthesis of the required conditions are as follows:

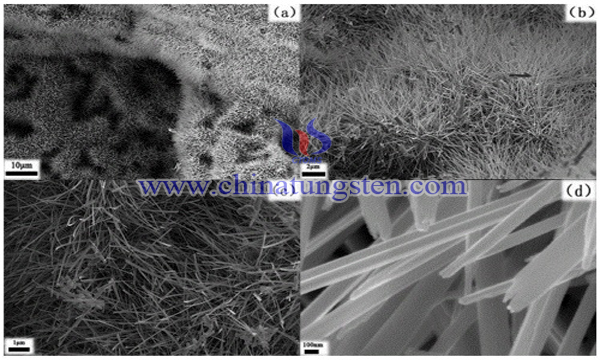

Tungsten Oxide Vacuum Thermal Oxidation Method

- Details

- Category: Tungsten Information

- Published on Saturday, 24 February 2018 14:45

Tungsten metal is generally more stable, with a melting point above 3400 ° C and a boiling point above 5700 ° C. In an oxygen environment, when the temperature is above 600 ℃ will be rapidly oxidized to tungsten trioxide. Tungsten oxide materials can be prepared by vacuum thermal oxidation.

sales@chinatungsten.com

sales@chinatungsten.com