Preparation of Spherical Tungsten Carbide in Foreign Countries

- Details

- Category: Tungsten Information

- Published on Friday, 02 March 2018 19:57

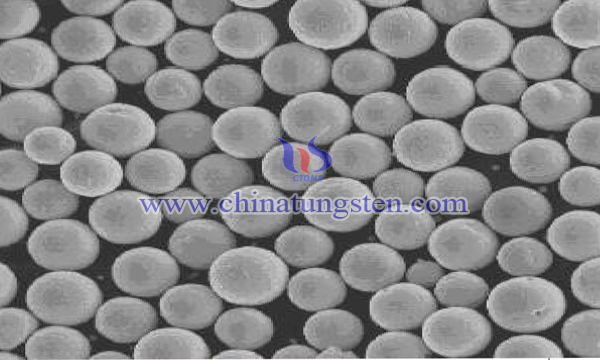

Spherical tungsten carbide powder is an important thermal spraying material. It is playing a more and more important role in electronic information, metallurgy, machinery and other industries. Compared with the ordinary multi angle tungsten carbide powder, the spherical tungsten carbide powder has many differences.

The chemical composition of the spherical tungsten carbide powder is stable, the hardness is high, the microstructure is fine equiaxed dendrite, and there is no hypereutectic and hypoeutectic. There is no stress concentration and micro crack, no sharp edge angle, and higher toughness and wear resistance than crushed powder. At the same time, the structure of spherical tungsten carbide powder is uniform and compact, which is favorable for surfacing and thermal spraying. The coating material has high wear resistance and toughness and excellent performance. Therefore, the preparation technology of spherical tungsten carbide powder is also different from the traditional method.

At present, the research on cast tungsten carbide powder at home and abroad focuses on two aspects: the domestic production is mainly focused on the improvement of traditional production technology, and as far as possible, the tungsten carbide powder with regular shape and fine structure is obtained. There are four kinds of tungsten carbide powders prepared by some special techniques in foreign countries. There are few kinds of tungsten carbide powders prepared by some special techniques in foreign countries.

1.Centrifugal rotation method: the tungsten powder is used as the raw material, and it is mixed evenly with the carbon black in the disc mill. Then, the mixture was continuously supplied into a water-cooled copper crucible and melted using an electric arc to prepare a molten cast tungsten carbide. The liquid through the nozzle in the crucible of cast tungsten carbide sprayed to the surface water or concave turret rotating tube, rotate at a certain speed according to the requirement of the product's granularity. The centrifugal force is dispersed into the droplet, and the droplet shrinks into spherical particles automatically, and the cast tungsten carbide particles are freely fallen from the rotating platform or rotary pipe to the bottom of the water cooling chamber.

2.Swirling atomization method: the mixture of tungsten, tungsten carbide, return material and carbon black is prepared according to the carbon content of the eutectic point of cast tungsten carbide, and the propeller continuously propes the mixture to the outlet of the mixture by screw propeller. The arc produced by electrodes is used to form a high temperature above 3000 degrees in the smelting chamber, which melts the mixture in a short time, decomposes and absorb carbon to form WC and W2C. The molten liquid continuously drops to a high-speed rotary table with a water cooled jacket under the action of gravity. The molten liquid is dispersed into many small liquid beads by centrifugal force, spattering along the tangential direction, cooling and crystallizing at a very fast speed, and finally falling into the cooling storage chamber.

The above two methods, the application of the centrifugal spinning method is more common. The atomization temperature is higher and the production efficiency is low. The induction heating spheroidization process is longer, while the gas atomization method has higher requirement for the equipment.

- Tungsten Powder Manufacturer & Supplier, Chinatungsten Online: tungsten-powder.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com