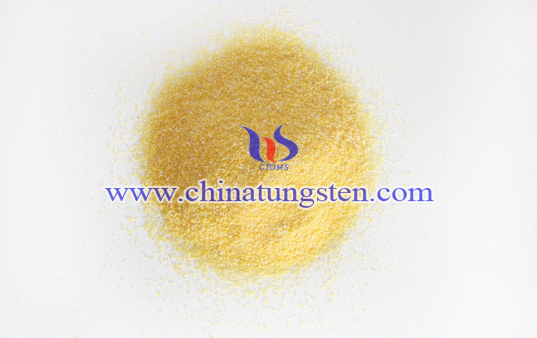

Pd / WO3 Catalyst

- Details

- Category: Tungsten Information

- Published on Friday, 02 March 2018 09:56

The defect tungsten oxide has a certain reduction ability, and the two reactants are directly synthesized by in-situ method at room temperature to synthesize Pd / WO3 composite material. This kind of mild, simple and easy synthesis method, obtained Pd nanoparticles smaller particle size, and evenly distributed in the tungsten oxide nanowires surface.

The Pd / WO3 composite catalyst synthesized by the in-situ synthesis method not only has a simple and convenient synthesis method but also has a high catalytic activity and confirms the good catalytic application prospect of the Pd / WO3 composite material.Pd / WO3 nano catalyst can still maintain high catalytic activity, ethylbenzene yield can reach more than 95%, indicating that the catalyst in the process of recycling can maintain a relatively stable catalytic activity.

There are three possible reasons for the high catalytic activity of Pd / WO3 catalyst: First, the WO3 material was directly reduced to Pd nanoparticles by in-situ reduction due to the presence of defects. And supported on the surface of WO3. This simple and gentle method keeps the surface of the Pd / WO3 composite catalyst clean. Secondly, Pd nanoparticles obtained by in-situ reduction are uniformly distributed on the surface of tungsten oxide nanoparticles. And the smaller the particle size of the nanoparticles, the better the distribution, morphology and size make the noble metal nanoparticles show better catalytic activity. Finally, due to the strong interaction between the metal and the support, the catalytic performance of the catalyst can be effectively improved.

- Tungsten Oxide Manufacturer & Supplier, Chinatungsten Online: www.tungsten-oxide.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com