Nano-alumina Coated Tungsten Powder Preparation by Freeze-drying

- Details

- Category: Tungsten Information

- Published on Wednesday, 22 May 2019 15:50

In order to ensure the uniformity of the dispersion of the composite particles and to improve the properties of the materials to the greatest extent, it is often required that the doped phase particles be coated on the surface of the matrix particles to form a coating to achieve the best mixing degree.

Surface Amphiphilic Nano Tungsten Molybdenum Sulfide Hydrogenation Catalyst

- Details

- Category: Tungsten Information

- Published on Monday, 20 May 2019 23:19

Suspension bed hydrogenation is an advanced technology for preparing liquid fuel oil from heavy unconventional oil. Suspension bed hydrogenation process requires catalyst with high activity, high dispersibility, high stability and good economy. Tungsten sulfide and molybdenum sulfide catalysts have been used as hydrogenation catalysts in petroleum processing. They are widely used in hydrodesulfurization, hydrodenitrification and other reactions. They are very promising catalysts for heavy oil hydrogenation in suspension bed process to produce clean fuel.

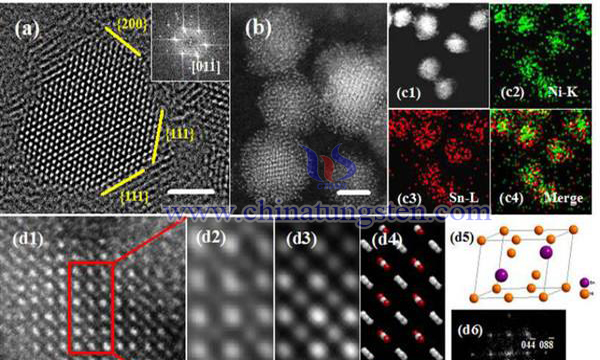

Ytterbium Erbium Doped Lead Tungstate Upconversion Materials

- Details

- Category: Tungsten Information

- Published on Monday, 20 May 2019 23:03

In recent years, more and more studies have been carried out on the properties of Er-doped materials, including infrared-visible up-conversion, optical and electrical properties of Er, as well as the progress and development of laser diodes, which have attracted unprecedented attention to Er-doping and luminescence.

Scheelite Beneficiation Wastewater Treatment Process

- Details

- Category: Tungsten Information

- Published on Monday, 20 May 2019 22:45

Under the existing technical system, a large amount of sodium silicate (sodium silicate) is usually added to the flotation process of scheelite to form a very stable colloidal dispersion system of fine particles in the pulp, which is conducive to flotation. However, a large amount of water glass wastewater has also been produced after flotation.

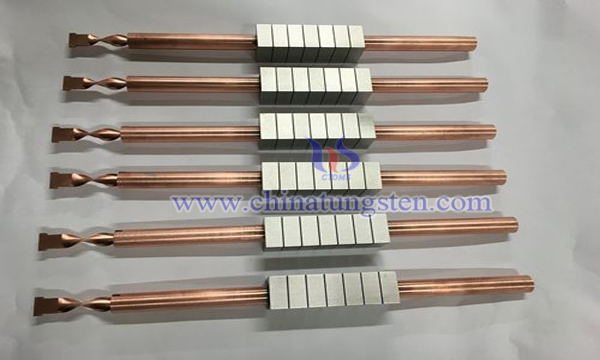

Tungsten-Titanium-Tantalum-Cobalt Cemented Carbide Coated Preparation With Silicon Dioxide

- Details

- Category: Tungsten Information

- Published on Monday, 20 May 2019 22:36

The traditional preparation methods of sintered W-Co cemented carbides are usually composed of WC-TiC compound carbides and WC powder, Co powder through proportioning, ball milling, drying, mixing of forming agents, pressing and sintering. The toughness and flexural strength of the tungsten-cobalt-titanium cemented carbides prepared by this method have been improved, but the density and hardness of the materials are low, and the high temperature resistance is poor, so they can not be used as high-speed cutting tools. Tools can only be used for rough or semi-finish machining.

Tungsten Trioxide Nanosheets Preparation by Thermal Oxidation

- Details

- Category: Tungsten Information

- Published on Monday, 20 May 2019 22:23

Tungsten trioxide is an important semiconductor material, which has important applications in gas sensing, catalysis, photoelectric conversion, field emission and other fields. Tungsten trioxide nanosheets with two-dimensional structure have attracted more and more attention in recent years because of their unique photoelectric properties.

Tungsten Carbide-based Multi-component Nanocomposite Ceramic Mould

- Details

- Category: Tungsten Information

- Published on Sunday, 19 May 2019 21:53

Ceramic cutting tools have high hardness and wear resistance, and show excellent cutting performance in high-speed cutting and dry cutting. They are a kind of tool materials with great development prospects. Ceramic materials have excellent thermal stability and wear resistance. They are ideal materials for manufacturing forming dies. They have great development prospects, but their toughness is very poor, so they have not been widely used in the die industry.

Tungsten Carbide Dispersion Enhanced Tungsten Treatment Process

- Details

- Category: Tungsten Information

- Published on Sunday, 19 May 2019 21:38

Tungsten has many advantages, such as high melting point, high density, high strength, high hardness, low thermal expansion coefficient, excellent corrosion resistance and good processing performance, so it is widely used in aviation, aerospace, electronics, chemical industry, military weapons and other fields.

Ultrafine Tungsten Powder Preparation by Raw Liquid Chemical Method

- Details

- Category: Tungsten Information

- Published on Sunday, 19 May 2019 21:14

Tungsten has been widely used because of its high melting point (3410 ℃) and excellent physical and chemical properties, such as rocket and aircraft engine parts, gas rudder control components, rocket's forebody, contact plug, radiator and so on.

Nano-solid Rhombic Silver Tungstate Preparation by Microwave Irradiation

- Details

- Category: Tungsten Information

- Published on Sunday, 19 May 2019 21:09

Silver tungstate material is a kind of important metal tungstate material. It has unique crystal structure and stable physical and chemical properties. Therefore, it can be used as a good luminescent matrix material, photocatalytic material and inorganic anti-bacterial material. It has bright application prospects in scintillator preparation, photocatalysis, medical environmental protection and other fields.

sales@chinatungsten.com

sales@chinatungsten.com