Intel's 10-nm Cobalt Resistance Layer will Replace Tungsten

- Details

- Category: Tungsten Information

- Published on Sunday, 05 May 2019 21:35

In recent days, Intel can be said to be sitting on the needle. Since AMD released the Rzen series of processors, AMD has regained a lot of market share from Intel with its advanced multi-core architecture and excellent comprehensive performance. In the face of competitors' catch-ups and upgrades, the toothpaste factory no longer dared to squeeze toothpaste, and sacrificed many techniques at the bottom of the box.

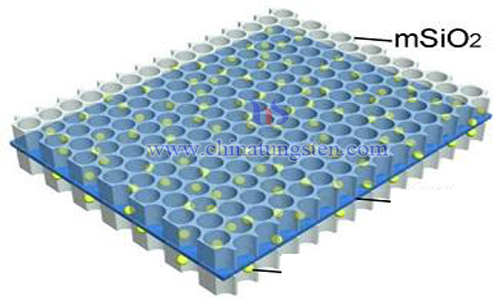

Spherical Mesoporous Silica Supported Phosphotungstic Acid Composite Catalyst

- Details

- Category: Tungsten Information

- Published on Sunday, 05 May 2019 21:26

Sulfuric acid and hydrochloric acid are commonly used as catalysts for the synthesis of ethyl acetate. In addition to traditional inorganic acids, there are solid superacids and ionic liquids supported on mesoporous materials. The inorganic acid catalyst corrodes the instrument seriously, and the homogeneous catalytic products are not easy to separate, which is easy to produce waste acid waste liquid and other pollutants. Solid acid also has the disadvantage of serious corrosion to the instrument, and the catalytic activity decreases quickly and the cost is high.

High Flatness Pure Tungsten Plate Preparation

- Details

- Category: Tungsten Information

- Published on Sunday, 05 May 2019 21:16

Tungsten metal is widely used due to its high melting point, high modulus of elasticity, good shock resistance and corrosion resistance, high electrical conductivity, thermal conductivity and excellent thermal fatigue resistance, and low expansion coefficient.

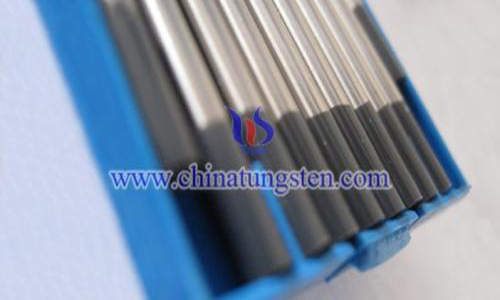

Process Optimization of Multi Rare Earth Tungsten Electrode

- Details

- Category: Tungsten Information

- Published on Sunday, 05 May 2019 21:05

Tungsten electrodes are the key materials in inert gas shielded welding and plasma welding, cutting, spraying, melting and special electric light sources. At present, most of them are tantalum tungsten electrodes (including ThO2) and tantalum tungsten electrodes (including CeO2). The thorium-tungsten electrode will bring radiological hazard to the environment and human health during its production and use; the thorium-tungsten electrode can replace the thorium-tungsten electrode only in the small-size welding tungsten electrode.

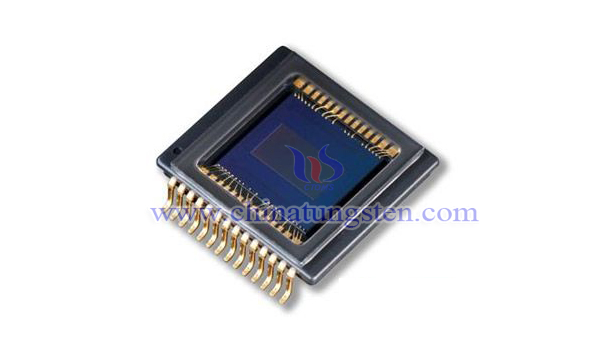

Metallic Tungsten Film Imaging Sensor Application

- Details

- Category: Tungsten Information

- Published on Sunday, 05 May 2019 20:56

With the development of semiconductor technology, the manufacture of camera sensor technology (CIS: CMOS image sensor) with metal oxide semiconductor technology has become a mainstream process in the field of emerging imaging. Among them, the metal film has a good visible light reflection conduction property, and is widely used as a reflection or isolation layer of incident light in the industry.

In Situ Synthesis of Phosphotungsten Heteropoly Acid Catalysts Based on Magnetic Cellulose

- Details

- Category: Tungsten Information

- Published on Friday, 03 May 2019 14:56

Phosphotungstic acid and silicotungstic acid are the main members of the heteropoly acid family. They have high catalytic activity, good selectivity, no pollution to the environment and little corrosion to equipment. They are a kind of green catalysts with great development prospects. In practical applications, scholars believe that immobilizing heteropoly acids on matrix materials can not only make the catalyst easy to recover and continuous production, but also greatly improve the specific surface area and catalysis, which is conducive to improving product quality and reducing production costs.

Nano-alumina Coated Tungsten Powder Composite Preparation

- Details

- Category: Tungsten Information

- Published on Friday, 03 May 2019 14:43

High strength, high toughness, high hardness, light weight, high temperature resistance and corrosion resistance are the main development directions of high performance structural materials. Tungsten, with its excellent high temperature resistance, high strength and hardness, is an irreplaceable key material in many fields, especially in the field of national defense, military industry, aviation and aerospace.

Tungsten Recovery and Nickel from Waste Catalyst for Petroleum Hydrogenation

- Details

- Category: Tungsten Information

- Published on Friday, 03 May 2019 14:24

Nickel-tungsten catalysts are widely used in hydrofining and hydrocracking. Their main components are about 25% tungsten trioxide, 2% nickel oxide, 50% alumina, 5% silicon dioxide and a small amount of iron and vanadium. Waste nickel-tungsten catalysts contain tungsten, nickel and other metals. If they can be recycled, they will produce enormous economic benefits. At the same time, the pollution and damage to the environment caused by waste nickel-tungsten catalysts are avoided.

Mesoporous Cerium-Tungsten-Aluminium Composite Oxide Supported Denitrification Catalyst

- Details

- Category: Tungsten Information

- Published on Tuesday, 30 April 2019 17:02

Nitrogen oxides (NOx) emitted from coal-fired power plants are recognized as one of the three major atmospheric pollutants, which can cause environmental problems such as acid rain, ozone layer destruction, greenhouse effect, and seriously endanger the earth's ecological environment and human health.

New Manufacturing Scheme of Rare Earth Tungsten Electrode

- Details

- Category: Tungsten Information

- Published on Tuesday, 30 April 2019 16:54

At present, tungsten-rare earth oxide electrode materials for argon arc welding, plasma cutting and steelmaking at home and abroad are manufactured by powder compaction, sintering and deformation.

sales@chinatungsten.com

sales@chinatungsten.com