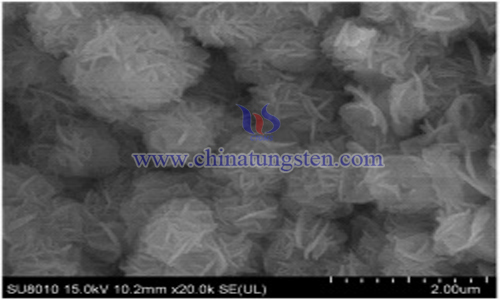

Petal-shaped Tungsten Sulfide Nanosphere

- Details

- Category: Tungsten Information

- Published on Sunday, 19 May 2019 21:02

At present, energy consumption and environmental problems have become the focus of attention all over the world. As the highest energy density, clean and efficient renewable energy, hydrogen is the most potential new energy in the 21st century. It is expected to replace fossil energy in people's production and life in the near future.

Spherical Single Crystal Tungsten Powder Preparation for Thermal Spraying

- Details

- Category: Tungsten Information

- Published on Tuesday, 14 May 2019 17:28

Thermal spraying using spherical single crystal tungsten powder to prepare thermal spraying technology is a rapidly developing surface strengthening technology. It uses special equipment, uses heat source to heat metal or non-metal materials to melt or semi-melt state, sprays them to the surface of the workpiece with high-speed airflow, forms coatings, and improves the wear resistance and corrosion resistance of the workpiece.

Activated Carbon Supported Silver Phosphomolybdate Tungsten Heteropolyacid Catalyst

- Details

- Category: Tungsten Information

- Published on Tuesday, 14 May 2019 17:23

Ketal is an important intermediate in chemical industry. It is often used for the protection of ketones and even as a special reaction solvent. Ketal is superior to parent carbonyl compounds in floral and fruity aroma, most of which have special aroma. As a new type of perfume, ketal has been widely used in daily chemical and food industries in recent ten years.

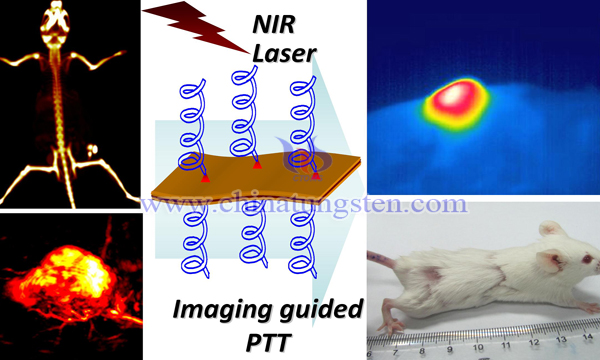

Nano Tungsten Disulfide Medical Application

- Details

- Category: Tungsten Information

- Published on Tuesday, 14 May 2019 17:17

With the increasing complexity of living environment, cancer is becoming the most serious serious disease endangering human health. Basic research and effective treatment are considered as the key link and effective means to cure cancer. Compared with traditional radiotherapy, chemotherapy and surgical treatment, targeted drug carriers with high selectivity and low toxicity to cancer cells and little toxicity to normal cells in the course of treatment are considered to be one of the most effective methods to combat cancer.

Graphene Supported Tungsten Carbide Catalyst

- Details

- Category: Tungsten Information

- Published on Tuesday, 14 May 2019 17:14

Hydrogen is a green alternative to fossil fuels. It is of great significance to prepare and store hydrogen on a large scale and at a low cost.

Fine Wolframite Flotation with Naphthalene Phthalate Dihydroxamic Acid

- Details

- Category: Tungsten Information

- Published on Tuesday, 14 May 2019 17:10

Hydroxamic acid is a kind of organic compound. It is carboxylic acid derivative substituted by oxime group in carboxylic acid molecule. It is a very weak organic acid. Industrial hydroxamic acid is a reddish brown oily liquid. The collector based on hydroxamic acid has good selectivity, but its collecting ability is slightly lower than oleic acid. However, it is just suitable for fine wolframite floatation. For example, a mine in southern Jiangxi Province used naphthalene phthalate Dihydroxamic Acid as the main collector to recover tungsten slime.

Tungsten-Silicon Thin Films Prepared by Magnetron Co-Sputtering

- Details

- Category: Tungsten Information

- Published on Sunday, 05 May 2019 22:25

Superconducting nanowire single photon detector (SNSPD) is a kind of highly sensitive photodetector which uses the nonequilibrium Thermo-electronic effect in superconducting nanowire to detect single photon signal. It has the characteristics of low dark count, fast detection speed, wide response spectrum and high efficiency. It is a research hotspot in the field of single photon detection technology.

Multi-stage Tungsten Particle Reinforced Aluminum Matrix Composites

- Details

- Category: Tungsten Information

- Published on Sunday, 05 May 2019 22:18

Tungsten particulate reinforced aluminium matrix composite is a kind of lightweight structural and functional integrated material with high temperature resistance, high strength and high wear resistance. It has great application potential and practical value, and has a wide range of applications in aviation, aerospace, automobile and electronics.

Carbon-Supported Ferric Carbide-Tungsten Carbide Composite Catalyst

- Details

- Category: Tungsten Information

- Published on Sunday, 05 May 2019 22:11

It was found that tungsten-based transition metal catalysts have excellent platinum substitution function. However, the agglomeration of nanoparticles and the existence of low density active centers in the synthesis process still puzzle the synthesis of such materials.

Tungsten Trioxide Nanostructures by Hydrothermal Method Preparation

- Details

- Category: Tungsten Information

- Published on Sunday, 05 May 2019 21:46

Tungsten trioxide nano-multistage structure refers to nanowires, nanorods, nanosheets and other nanostructures formed by the combination of two or more components. At present, some scholars have prepared corresponding materials by thermal evaporation, electrospinning and other processes, but these preparation methods will involve high temperature, high vacuum, high technical difficulties and other issues, which are contrary to the development of low power consumption.

sales@chinatungsten.com

sales@chinatungsten.com