Tungsten Recycling from Tantalum Niobium Smelting Wastewater

- Details

- Category: Tungsten Information

- Published on Monday, 02 July 2018 10:22

China has successfully produced high-purity tantalum niobium products from various tantalum niobium ores, and it has formed a considerable scale of production capacity. In the process of wet production of tantalum and niobium, a large number of rare elements (such as Ti, Cr, Re, W, Ni, etc.) as well as common elements (such as Sn, Ca, Fe, Mo, etc.) are associated with the raw mineral.

In the decomposition extraction process, a large number of extractive residue and residue will be produced, including many valuable metal elements (such as tin, tungsten, titanium, etc.), while most of the tungsten is left in the extraction residue, which has a large amount of residual liquid and has a certain value of recovery. The method for recovering tungsten from tungsten containing wastewater includes the following steps:

(1) Adding 18 mol/L of concentrated sulfuric acid 90L to the 1000L residue containing tungsten 6.8g/L and 8.7 mol/L total tantalum niobium, the total acid was higher than 10mol/L.

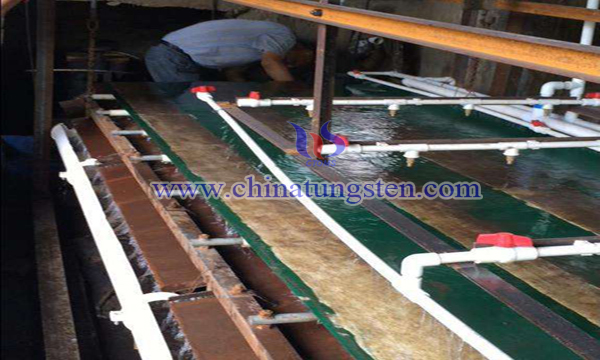

(2) In a 8 stage countercurrent mixed extraction tank, a mixed organic 360L is added to the residual liquid containing tungsten tantalum and niobium. By countercurrent mixed extraction by O/A=1:3, the organic containing tungsten is obtained. The total acidity of the tungsten containing tungsten is 3.8mol/L and the tungsten content is 20.3g/L.

(3) The 1.5mol/L sulfuric acid solution 120L was added into the organic solution containing tungsten, and the 6 stage countercurrent mixed extraction tank was set up. The acid washing and stripping were carried out compared to O/A=3:1. The total acidity of 7.4mol/L and tungsten containing 60.8g/l were obtained.

(4) Tungsten was added to tungsten solution by adding 500 quartz powder. Silica in the quartz powder reacts with free hydrofluoric acid in the extractive residue to produce fluorosilic acid (H2SiF6). The addition of quartz powder is 1.4 times the theoretical amount, and the hydrofluoric acid in the tantalum niobium extraction residue after reaction 16h is less than 1.0mol/L, the tungsten in the solution forms tungstate after the quartz powder is complexed with fluorine.

(5) The wet tungstic acid was filtered and washed for 2 times by plate and frame. After solid-liquid separation and drying in oven, 8.7kg of tungstic acid was obtained.

The purity of tungstic acid was 73.3%, and the recovery of tungsten was 93.8%. It not only reduces the treatment cost of waste liquid in production, but also increases economic and social benefits.

- Tungsten Manufacturer & Supplier, Chinatungsten Online: www.chinatungsten.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com