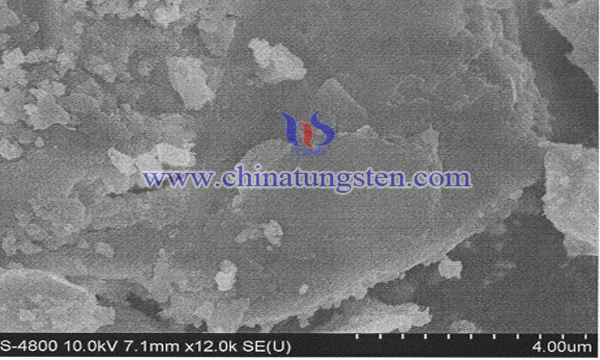

A Preparation of Purple Tungsten Oxide with Nano-Needle Shape

- Details

- Category: Tungsten Information

- Published on Saturday, 25 May 2019 13:53

As a semiconductor material (with a band gap of 2.4 to 2.8 eV), tungsten oxide has an extremely wide range of applications in photoelectrochemistry. Among them, purple tungsten oxide (W18O49) has attracted special attention from researchers because of its unique properties and structure.

A Preparation Method of Two-dimensional Zinc Tungstate Nanosheets by Microwave Irradiation

- Details

- Category: Tungsten Information

- Published on Friday, 24 May 2019 23:58

Zinc tungstate has high photocatalytic activity and excellent single crystal scintillation properties; thus, it is one of the most promising photocatalysts and high-energy physical scintillation materials. It possesses a high potential to applicate in photocatalytic synthesis and complex ultra-micro device preparation.

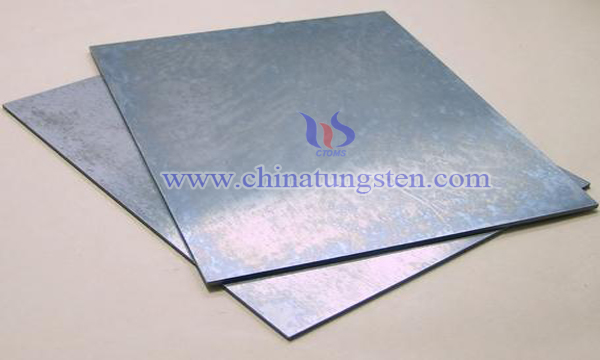

Tungsten Slab Preparation by Resistance Sintering

- Details

- Category: Tungsten Information

- Published on Thursday, 23 May 2019 17:24

Tungsten slab is the precursor form of tungsten plate. Tungsten plate is mainly used to make temperature standard light source, tungsten evaporation boat, electron tube shed, heat shield, high temperature furnace component, X-ray tube tungsten target and so on. Satisfactory results have been obtained in these fields. With the continuous development of science and technology, the application of tungsten plate has been expanding, especially in nuclear energy, medical devices and other fields.

Paper-based Bamboo Curtain with Nano Tungsten Oxide Photocatalyst

- Details

- Category: Tungsten Information

- Published on Thursday, 23 May 2019 17:19

Because of the change of life and work form, modern people spend more and more time in indoor environment. Almost 90% of the time is spent indoors. As a result of poor indoor air quality, a large number of "sick buildings" and the number of people suffering from "building disease syndrome" are increasing.

Cadmium Tungstate Nanowires Preparation by Microwave Method

- Details

- Category: Tungsten Information

- Published on Thursday, 23 May 2019 17:13

Cadmium tungstate (CdWO4) single crystal is subordinate to wolframite structure (monoclinic system), and its melting point is 1289 ℃. It is a very important scintillator material with excellent performance, high luminescence efficiency and energy resolution. It can emit light blue to yellow spectra under the action of ultraviolet light. It has been widely used in light emitting diodes and super large screen displays.

Recovery of Various Valuable Metals From Tungsten Slag

- Details

- Category: Tungsten Information

- Published on Thursday, 23 May 2019 17:09

Tungsten slag is produced in tungsten smelting process, that is, tungsten ore and waste tungsten carbide raw materials are decomposed by wet method in high temperature or aqueous solution to obtain primary tungsten products (sodium tungstate, ammonium paratungstate) and solid waste slag (i.e. tungsten slag).

Q-switched Laser Absorbing Material-Nano Tungsten Disulfide

- Details

- Category: Tungsten Information

- Published on Wednesday, 22 May 2019 16:40

Q-switched laser technology is a technology that compresses the general output continuous laser energy into a very narrow pulse to emit, so that the peak power of the light source can be increased by several orders of magnitude. Because Q-switched lasers can obtain high peak power and narrow pulse width, they are widely used in industrial processing and scientific research fields, such as the manufacture of ultrafine semiconductors, terahertz wave equipment and so on.

Five Common Schemes for Tungsten Nanowires Preparation

- Details

- Category: Tungsten Information

- Published on Wednesday, 22 May 2019 16:26

Tungsten metal has excellent physical and chemical properties, such as high melting point (3410 ℃), high density (19.35g/cm3), high conductivity/thermal conductivity, excellent high temperature strength and hardness, low work escape, very low thermal expansion coefficient and vapor pressure, and good corrosion resistance, which makes tungsten an important functional material and high temperature structural material.

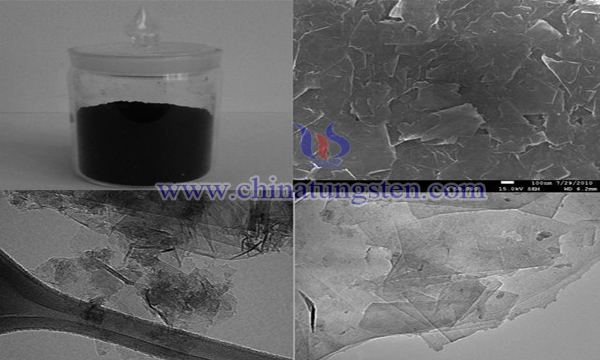

Monodispersed Tungsten Disulfide Nanosheets

- Details

- Category: Tungsten Information

- Published on Wednesday, 22 May 2019 16:13

Non-noble metal sulfides are layered materials with graphene-like structure, which have good applications in catalysis, microelectronics, semiconductor and other fields. Tungsten sulfide and molybdenum sulfide catalysts have been used as hydrogenation catalysts in petroleum processing. They are widely used in hydrodesulfurization, hydrodenitrification, hydrodearomatization, hydrodeoxygenation and hydrodemetallization.

Solvothermal Synthesis of Tungsten Diselenide Nanosheets in One Step

- Details

- Category: Tungsten Information

- Published on Wednesday, 22 May 2019 16:00

As the main transition metal selenide, tungsten diselenide (WSe2) is a kind of engineering material and functional material with many special properties. WSe2 crystal has a hexagonal sandwich structure similar to MoS2. Each WSe2 molecule layer is composed of two Se atom layers with a W atom layer. The W atom layer and Se atom layer are covalently bonded, while the adjacent WSe2 layers are separated by Se layer with a long distance and a weak van der waals force.

sales@chinatungsten.com

sales@chinatungsten.com