Tungsten-based Oxide Electrochromic Films

- Details

- Category: Tungsten Information

- Published on Thursday, 30 May 2019 17:47

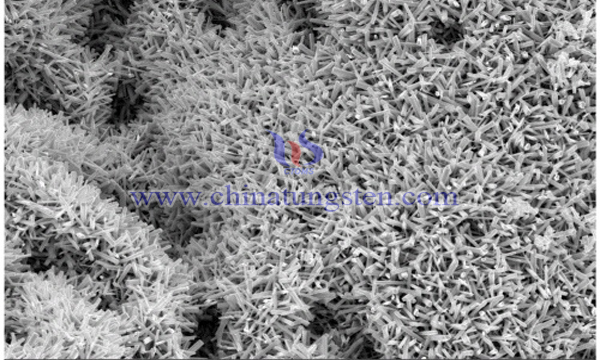

Tungsten-based oxide electrochromic film is a phenomenon in which the optical properties of materials change reversibly under the action of applied electric field. It can be applied to building intelligent windows, automotive anti-glare rearview mirrors, display devices and other fields. As a stable non-stoichiometric tungsten oxide, W18O49 can synthesize a variety of microstructures by various wet chemical methods, showing excellent performance in electrochromic, sensor and other fields.

Synthesis Of Ethyl Acetate Using Phosphotungstic Acid Catalyst

- Details

- Category: Tungsten Information

- Published on Thursday, 30 May 2019 13:33

Ethyl acetate is a widely-used fine chemical product widely used in cellulose acetate, ethyl cellulose, chlorinated rubber, vinyl resin, cellulose acetate, synthetic rubber, paints.Traditionally, the esterification catalytic reaction of ethyl acetate is generally by using an acid as a catalyst. In addition to the conventional inorganic acid, there is also a solid super acid such as a mesoporous material.

Plasma Electrolytic Oxidation to Prepare Tungsten Trioxide(WO3)

- Details

- Category: Tungsten Information

- Published on Thursday, 30 May 2019 13:11

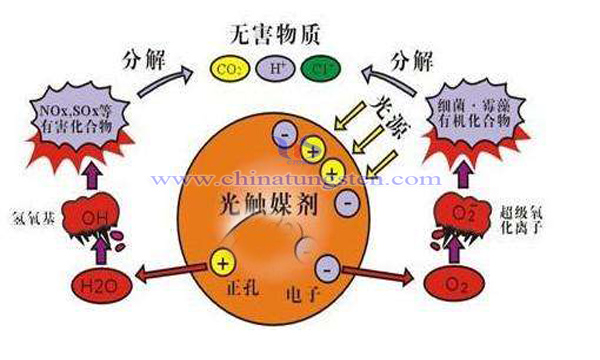

With the rapid development of modern industry, a large amount of industrial wastewater, such as untreated or untreated, is directly discharged into the natural world, causing enormous pollution damage to the environment and seriously affecting human health. Photocatalysis refers to the fact that when the visible light is irradiated onto the semiconductor powder in the aqueous solution, the dye molecules are decomposed into CO2, H2O and the like which are harmless to the environment.

Dodecylamine Phosphotungstate Catalyst

- Details

- Category: Tungsten Information

- Published on Wednesday, 29 May 2019 16:49

Esterification is an important unit reaction in organic synthesis. In traditional methods, liquid acids such as sulfuric acid, phosphoric acid and p-toluene sulfonic acid are often used as catalysts. There are some problems such as difficult separation of catalysts from products, high energy consumption, corrosion equipment and environmental pollution.

Dendritic Barium Tungstate Nanocrystals Preparation by Microemulsion Method

- Details

- Category: Tungsten Information

- Published on Wednesday, 29 May 2019 15:44

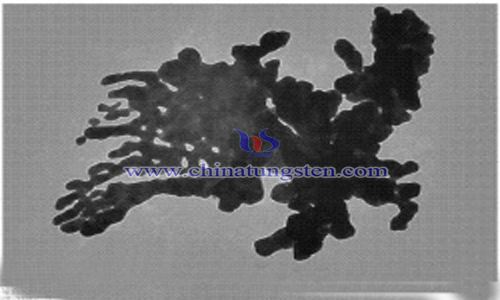

With the increasing maturity of nano-preparation technology, the development of nano-materials with different morphologies and sizes and the study of the effects of size and morphology on the properties of materials have become one of the main directions of nano-technology research. The traditional inorganic luminescent materials are prepared into nano-materials with certain morphology. The performance of luminescent materials can be further improved by using nano effect.

Phosphotungstic Acid Catalyzed Mixed Alcohol

- Details

- Category: Tungsten Information

- Published on Wednesday, 29 May 2019 15:37

Esters are widely used as solvents, perfumes and preservatives. They are very important in food, industry, daily chemical industry and pharmaceutical production. Esterification is one of the most important reactions in organic synthesis. It is usually the reaction of organic acids and alcohols to produce esters and water. Traditional schemes have serious environmental pollution.

An Efficient Preparation Method of Tungsten Selenide (Wse2) Film

- Details

- Category: Tungsten Information

- Published on Wednesday, 29 May 2019 13:19

The tungsten selenide (WSe2) film is one of the top of thermal insulating materials, its thermal conductivity is about one hundred thousandth diamond( apparently the material with the best thermal conductivity). It is the material with the lowest thermal conductivity.

Tungsten Quantum Dot Photocatalyst

- Details

- Category: Tungsten Information

- Published on Wednesday, 29 May 2019 11:54

Photocatalysis, as a new wastewater treatment technology, has shown broad application prospects in the advanced treatment of organic wastewater. In addition, photocatalysts are also widely used in building decoration markets and indoor cars. Photocatalysis process has almost no selectivity for the degradation of organic matter, and can completely mineralize organic pollutants, without secondary pollution.

The Preparation process of High-efficiency Copper-VOT Photocatalysts

- Details

- Category: Tungsten Information

- Published on Wednesday, 29 May 2019 01:20

With the increasing problems of energy and environment, the pollution of water resources by organic matter is particularly prominent, which not only affects human health, but also consumes a large amount of energy to eliminate such pollutants. Therefore, the development of new materials using photocatalytic technology to solve pollution has become a new research direction.

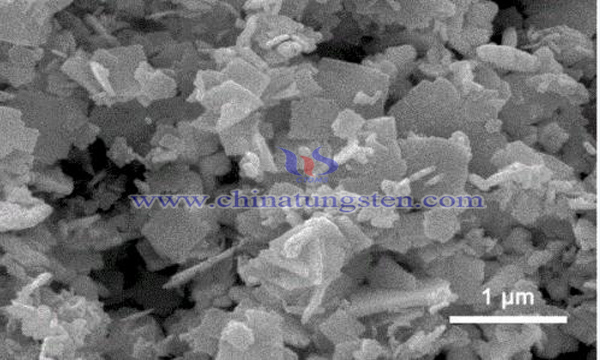

Bismuth Tungstate-Polyphenylamine Heterojunction Photocatalyst

- Details

- Category: Tungsten Information

- Published on Tuesday, 28 May 2019 22:18

At present, some new tungstate photocatalytic materials with visible light effect have been discovered by researchers. Semiconductor materials such as tungstate have good application prospects due to their unique structure and physicochemical properties, such as magnetic devices, scintillators, corrosion inhibitors and catalysts, which have become a research hotspot in recent years. For example, the catalytic material Bi2WO6 (band gap is only about 2.8eV), which is faster than the visible light response photocatalysis of TIO2, can mineralize harmful substances such as chloroform and acetaldehyde under visible light, and degrade them into CO2.

sales@chinatungsten.com

sales@chinatungsten.com