Nano Tungsten Carbide Preparation by Liquid Alkanes Reflux

- Details

- Category: Tungsten Information

- Published on Wednesday, 05 June 2019 17:45

Tungsten carbide is one of the most important materials in transition metal carbides. It has excellent properties such as high melting point, hardness, thermal stability and mechanical stability. It is widely used in making cemented carbide materials and has important applications in cermet, mechanical processing, metallurgical minerals, aerospace and other fields.

Polyaniline-Tungsten Carbide Composite Catalyst

- Details

- Category: Tungsten Information

- Published on Wednesday, 05 June 2019 17:34

Fuel cell is an electrochemical device that directly converts chemical energy into electrical energy. One of its key materials is electrode catalyst. For a long time, precious metals such as platinum and ruthenium have been widely used because of their excellent catalytic performance. Alloy catalyst can reduce the Pt loading and improve the catalytic efficiency, but the stability of catalyst needs to be improved.

Tungsten Carbide Coating Prepared by Plasma Spraying

- Details

- Category: Tungsten Information

- Published on Wednesday, 05 June 2019 17:32

Tungsten has the advantages of high melting point, high strength, high hardness and high wear resistance. In addition, it has low thermal expansion coefficient, good corrosion resistance and oxidation resistance, and good conductivity and thermal conductivity. Therefore, tungsten has been widely used in cutting-edge scientific fields, national defense industry and civil industry.

Sodium Tungstate Applied in Efficient Production of Phycocyanin

- Details

- Category: Tungsten Information

- Published on Wednesday, 05 June 2019 13:33

Phycocyanin is a fat-soluble natural carotenoid. Modern science finds that phycocyanin contains a special structure of propadiene and alkylene oxide. This special structure leads to many important physiological activities, such as anti-tumor. Activity, anti-obesity activity, antioxidant activity, regulation of blood sugar, scavenging free radicals, etc., have broad prospects for development in the fields of food, medicine, health care products, and beauty products.

Preparetion Method of 2H Phase Single-layer Tungsten Disulfide Nanosheet

- Details

- Category: Tungsten Information

- Published on Wednesday, 05 June 2019 13:12

Tungsten disulfide (WS2) has the same structure as molybdenum disulfide. It is a typical sandwich layer structure. Due to its relatively weak van der Walls force between layers, it can also be stripped into single or few layers of nanosheets. It is considered to be another equivalent. An important two-dimensional nanosheet material with unique physical, chemical and electrical properties.

Graphene-polyaniline-phosphotungstates Acid Composite Material

- Details

- Category: Tungsten Information

- Published on Wednesday, 05 June 2019 01:10

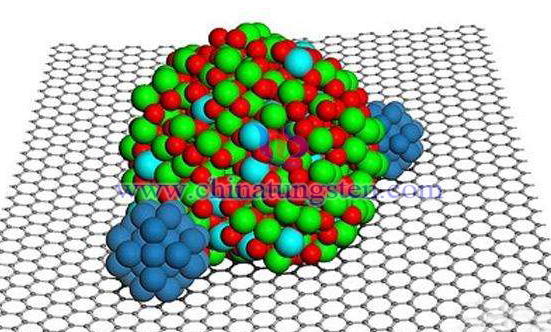

Phosphotungstate (H3PW12O40) is a kind of heteropolyacid polyoxometalate. Phosphotungstate is a well-developed positive electrode active material in heteropoly acid clusters due to its reversible multi-electron redox reaction. It can achieve a specific capacity of 260Ah/kg and excellent performance of rapid charge and discharge, and its capacity exceeds 150Ah/kg of the conventional Li2CoO2 lithium ion battery which has been commercialized.

Spherical Tungsten Powder Preparation by Radio Frequency Plasma

- Details

- Category: Tungsten Information

- Published on Tuesday, 04 June 2019 17:39

Spherical tungsten powder is mainly used in thermal spraying, filter materials, cathode and porous materials because of its good sphericity and fluidity and high compacting density. At present, the demand for high quality spherical tungsten powder is increasing day by day. In the field of thermal spraying, spherical tungsten powder is more uniform and compact because of its good fluidity and high compacting density.

Spherical Tungsten Carbide Synthesis by Template Method

- Details

- Category: Tungsten Information

- Published on Tuesday, 04 June 2019 16:05

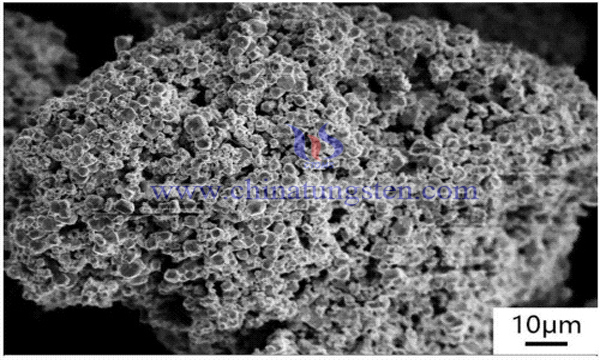

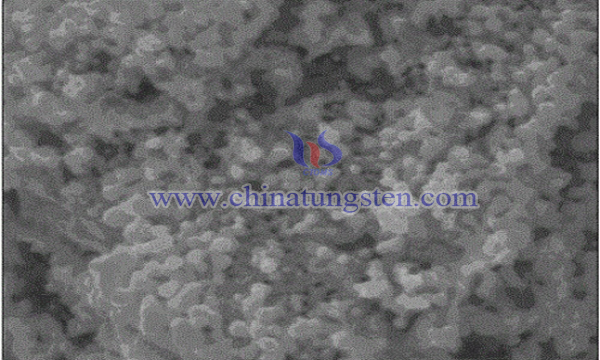

Spherical tungsten carbide powder has high hardness, high wear resistance, acid and alkali resistance, high chemical stability. It has wide potential application value in fuel cell anode, cathode catalyst material, gas sensor, petroleum catalyst and photocatalyst material.

Low Cost Chemical Method for Waste Tungsten Recovery

- Details

- Category: Tungsten Information

- Published on Tuesday, 04 June 2019 15:57

At present, waste tungsten is recycled by re-grinding inserts. But beyond a certain point, it is impossible to grind them again and the purity can not be improved. Therefore, further process is usually needed to complete the recovery of tungsten scrap.

Tungsten Slime Treatment by High Gradient Combined Magnetic Separation

- Details

- Category: Tungsten Information

- Published on Tuesday, 04 June 2019 15:50

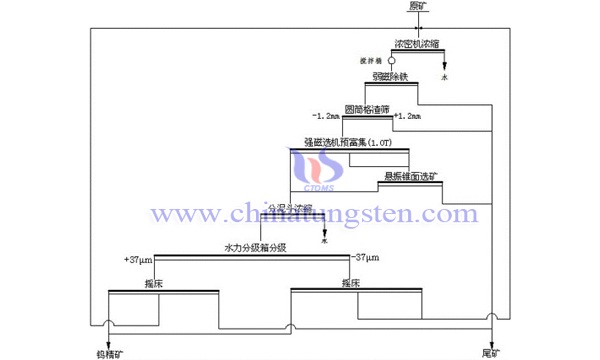

Wolframite has a large proportion and is brittle. Slime is easily produced in the process of mining and dressing. In the early stage, shaking bed and centrifugal gravity separation are mainly used to recover wolframite. Shaking bed surface zoning is obvious and easy to operate, but the unit area processing capacity is small, the recovery rate is low when treating fine mud, and metal is easily lost from fine mud. Although centrifugal concentrator has large processing capacity and high recovery efficiency for fine mineral particles, its water consumption is large, and it is difficult to achieve ideal indicators in actual industrial production.

sales@chinatungsten.com

sales@chinatungsten.com