Production Method of Tungsten Carbide Powder from Recycled Powder

- Details

- Category: Tungsten Information

- Published on Thursday, 02 August 2018 18:54

Tungsten carbide (WC) is an important raw material for the production of cemented carbide. The preparation processes of tungsten carbide are various, and the preparation of tungsten carbide powder from tungsten powder is the most widely used method.

Production Method of Tungsten Powder by Direct Reduction

- Details

- Category: Tungsten Information

- Published on Thursday, 02 August 2018 18:45

At present, the common method for producing tungsten powder with high green strength is by: using ammonium paratungstate (APT) as raw material, APT is sintered to form tungsten oxide (WO3, WO2.9), and then tungsten oxide is reduced by hydrogen to form tungsten powder. Finally the high-green-strength tungsten powder is obtained by screening and removing impurities.

Production Method of Tungsten Powder from Tungsten Waste

- Details

- Category: Tungsten Information

- Published on Thursday, 02 August 2018 18:39

Due to the important position of tungsten resources and the scarcity of stocks, the recycling of tungsten waste is highly valued, especially in the United States, Japan, Germany and other countries. For example, about 35% of tungsten products in the United States use recycled tungsten. Compared with developed industrial countries, the recycling of tungsten waste in China possesses a later start point and there are fewer specialized techniques.

Carbon Nanotube-Tungsten Carbide Composite Powder

- Details

- Category: Tungsten Information

- Published on Thursday, 02 August 2018 18:33

With the advent of nano-scale ceramic powders, related powder materials have also begun to be widely used as reinforcing phases of coatings. The use of nano-scale ceramic powder materials or carbon nanotubes helps to improve the mechanical properties of the coating, which has the effects of friction reduction and toughening have significant effects.

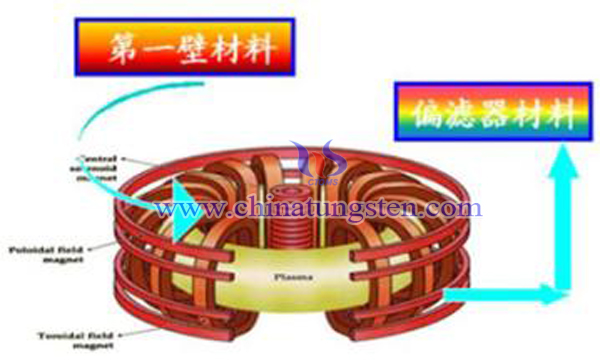

Tungsten-Based Plasma Facing Components

- Details

- Category: Tungsten Information

- Published on Thursday, 02 August 2018 18:15

Tungsten materials are considered to be plasma facing components (PFC) for the preparation of the International Thermonuclear Experimental Reactor (ITER) due to its high melting point, high sputtering threshold, high thermal conductivity, low vapor pressure, and low hydrogen isotope retention.

Almonty Industries to Improve Tungsten Concentrate Output at Panasqueira Mine in Portugal

- Details

- Category: Tungsten Information

- Published on Thursday, 02 August 2018 11:22

Almonty Industries Inc. is pleased to announce that the ore sorting equipment has arrived at its Panasqueira mine in Portugal. The equipment was released by customs last week and during the 23rd and 24th of July 2018, the entire installation arrived at the mine.

Niobium Tungsten Oxides Help Make Faster-charging Batteries

- Details

- Category: Tungsten Information

- Published on Thursday, 02 August 2018 11:20

Is there an alternative to nanostructuring electrode materials to speed up ionic diffusion in lithium-ion batteries and so increase their maximum power output and charging rates? Yes, according researchers at the University of Cambridge in the UK, who have shown that two complex niobium tungsten oxides can intercalate large amounts of lithium even when the oxides are microns in size.

Environmentally Friendly Tungsten-Based Catalysts

- Details

- Category: Tungsten Information

- Published on Wednesday, 01 August 2018 18:14

In order to implement the Montreal Protocol to protect the Earth's ozone layer, countries around the world have introduced zero-ODP values of hydrofluorocarbons (HFCs) and hydrofluoroolefins (HFOs) to phase out chlorofluorocarbons (CFCs) and hydrofluorides Chlorocarbons (HCFCs). At present, HFCs and HFOs have been widely used as refrigerants, cleaning agents, foaming agents, fire extinguishing agents, etchants, and etc.

High-Efficiency Method for Separating Tungsten and Molybdenum

- Details

- Category: Tungsten Information

- Published on Wednesday, 01 August 2018 17:38

With the continuous exploitation of high-quality tungsten-molybdenum ore resources, complex tungsten-molybdenum symbiotic mineral resources are gradually being consumed. However, the impurity content in tungsten product or molybdenum product seriously affects its performance. The most difficult impurity element to remove from tungsten products is molybdenum, while for molybdenum products, tungsten is the most difficult to separate. In order to improve the performance of tungsten and molybdenum products, separation of tungsten and molybdenum is necessary. Therefore, in order to efficiently utilize these tungsten-molybdenum symbiotic mineral resources, the separation of tungsten and molybdenum is the key.

Tungsten-Nickel Cemented Carbide with Strong Acid and Alkali Resistance

- Details

- Category: Tungsten Information

- Published on Wednesday, 01 August 2018 17:34

The flow meter is used to measure the flow rate and speed of the liquid when it is flowing. Typically, the movement shaft of a flow meter is made of stainless steel. It is well known that stainless steel has good corrosion resistance. The corrosion resistance of stainless steel depends on the alloying elements contained in the steel. Chromium is the basic element for obtaining corrosion resistance of stainless steel. In addition to chromium, commonly used alloying elements include nickel, molybdenum, titanium, niobium, copper, and nitrogen to meet the requirements of stainless steel structure and properties for various applications.

However, the flow shafts, which are exposed to chemicals such as strong acids and alkalis for a long time, would be corroded. In addition, stainless steel is added with other alloying elements, which makes the steel material impure, so there will be deviations in the magnetic field, resulting in inaccurate measurement. In order to improve the acid-base resistance of the material without magnetic properties, some scholars have proposed a preparation method of tungsten-nickel cemented carbide by:

The raw materials are prepared by weight percentage: 90% tungsten alloy (WC) powder, 9.6% nickel (Ni) powder and 0.4% chromium carbide (Cr3C2) powder; after the raw materials are subjected to mixed ball milling for 36 hours, the material is precipitated for 24 hours and dried for 100 minutes. ± 5 minutes, the temperature is controlled at 85 ° C ± 5 ° C; and then mixed with 10 ml of glue per 1 Kg of mixed raw materials, add SBS-modified binder (0.1Kg of SBS-modified binder per 1Kg of mixed raw materials); finally sintered in a vacuum furnace, control from 300 ° C to 1450 ° C, and then cool down to normal temperature, the product is released.

The WC powder has a particle size of 2.3 to 2.8 μm, the Ni powder has a particle size of 1.5 to 2.0 μm, and the Cr3C2 has a particle size of 2.0 to 2.6 μm.

Because WC powder, Ni powder and Cr3C2 powder are used as alloying elements, the acid and alkali resistance of the material can be improved, the service life is greatly prolonged, and nickel is used instead of the conventional cobalt in the material, so that the material is not magnetic, so it is made. The tungsten-nickel cemented carbide can be used to make the movement shaft of the acid-base flow meter and the movement shaft of the instrument that needs to avoid magnetic interference.

- Tungsten Alloy Manufacturer & Supplier, Chinatungsten Online: www.tungsten-alloy.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com