Adipic Acid Synthesis with Nano Tungsten Trioxide Catalyst

- Details

- Category: Tungsten Information

- Published on Saturday, 29 June 2019 23:10

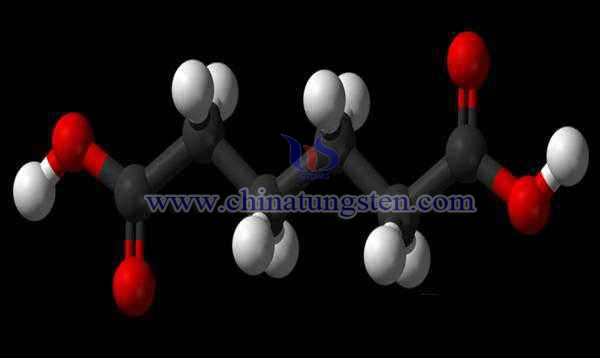

Adipic acid is an important organic dibasic acid, which is mainly used in synthetic fibers, namely nylon-66. The annual consumption of adipic acid is very large. At present, the traditional production process of adipic acid synthesis is still widely used in industry, that is, using concentrated HNO3 as oxidant. This process is very harmful to the environment.

Cesium Tungsten Bronze Ultrafine Powder Preparation

- Details

- Category: Tungsten Information

- Published on Saturday, 29 June 2019 23:02

Tungsten trioxide is recognized as an excellent electrochromic material. It has excellent properties in electrochromic, catalytic and gas sensitivity. Tungsten bronze, a composite oxide of tungsten bronze, generally refers to metal oxides with deep metallic luster, and is usually metal conductors or metal semiconductors.

Tungsten Carbide Supported Cobalt-Nickel Catalyst

- Details

- Category: Tungsten Information

- Published on Saturday, 29 June 2019 22:51

With the increasing consumption of petroleum resources, the new synthetic route of preparing high value-added liquid chemicals and other organic chemicals with natural gas as an alternative energy source has attracted great attention from all over the world. The preparation of syngas by partial oxidation of natural gas is an important intermediate link in the realization of natural gas conversion, and the research and development of efficient catalysts is the key.

Immobilized Phosphotungsten Heteropoly Acid Preparation by Extraction

- Details

- Category: Tungsten Information

- Published on Saturday, 29 June 2019 22:44

In the conventional preparation of phosphotungstic acid, a large amount of ether is used to extract the reaction liquid of phosphotungstic heteropoly acid, and a yellowish transparent oily ether-phosphotungstic heteropoly acid is obtained. The solid product of yellowish phosphotungstic heteropoly acid is obtained by blowing ether with air. Moreover, the ether used in the whole extraction process is difficult to recycle, resulting in waste of resources and environmental pollution.

Tungsten-Molybdenum Ore Recovery from Molybdenum Sulfide Flotation Tailings

- Details

- Category: Tungsten Information

- Published on Saturday, 29 June 2019 22:34

Tungsten and molybdenum are two non-renewable strategic mineral resources. Because of their unique properties, they are widely used in steel, military, aerospace, electronics, electrical appliances and chemical industries. With the development of social economy, the demand for tungsten and molybdenum is increasing, and the reserves of tungsten and molybdenum resources are decreasing sharply. However, there are a large number of poor, fine and miscellaneous refractory tungsten and molybdenum resources in our country. For refractory tungsten and molybdenum ores, especially for tungsten and molybdenum ores with high oxidation rate, no effective recovery method has been found.

Phosphotungstic Acid-Organometallic Framework Catalytic Material

- Details

- Category: Tungsten Information

- Published on Saturday, 29 June 2019 22:18

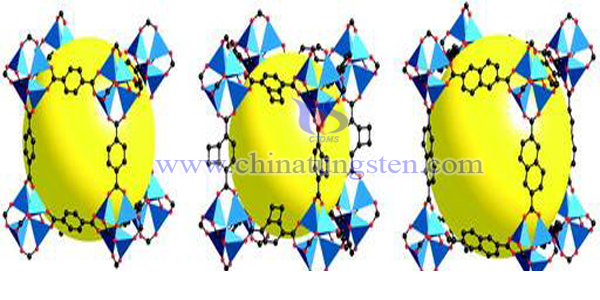

Biomass can be regarded as a promising alternative energy source for petroleum. The key to convert biomass into important energy materials and basic platform compounds is to convert cellulose, an important component of biomass, into glucose by directional hydrolysis.

Tungstate Red Phosphor

- Details

- Category: Tungsten Information

- Published on Saturday, 29 June 2019 22:08

White LED is a new solid-state lighting electric light source (SSL). Its principle and structure are different from those of previous vacuum electric light sources such as incandescent lamp and fluorescent lamp. SSL light source has many advantages, especially high light efficiency, energy saving, long life and pollution-free. It has great application value and prospects.

Tungsten Carbide-Titanium Carbide Solid Solution New Preparation Process

- Details

- Category: Tungsten Information

- Published on Saturday, 29 June 2019 21:51

The traditional method of preparing tungsten carbide-titanium carbide solid solution is to use industrial titanium dioxide and WC as raw materials, carbon black as reducing agent, mix with ball mill, and react in graphite tube electric furnace at the temperature of 2000-2300 ℃. The preparation method has the following shortcomings: first, the ball mill has low ball milling efficiency, mainly mixing effect on raw materials and little crushing effect. Second, the high reaction temperature makes the sintering growth of the prepared tungsten carbide-titanium carbide solid solution obvious.

SCR Catalyst Recovery Process Improvement

- Details

- Category: Tungsten Information

- Published on Saturday, 29 June 2019 21:15

SCR denitrification technology has the advantages of high denitrification efficiency, over 90%, good selectivity and reliable technology. Catalyst is the core of SCR denitrification technology. At present, the commonly used SCR denitrification catalyst is based on titanium dioxide as carrier, V2O5 as active component, WO3 or MoO3 as structural promoter. The activity of catalyst directly determines the efficiency of denitrification.

Titanium Tungsten Alloy by Molten Salt Electrolysis

- Details

- Category: Tungsten Information

- Published on Saturday, 29 June 2019 20:54

At present, the main methods for preparing Ti-W alloys are high temperature vacuum melting, powder metallurgy and mechanical alloying. However, these methods have some disadvantages, such as high production cost, complex process or low purity of products, which reduce the properties of Ti-W alloys and greatly limit their application.

sales@chinatungsten.com

sales@chinatungsten.com