Tungsten Alloy Counterweights in Aerospace Industry

- Details

- Category: Tungsten Information

- Published on Monday, 15 July 2019 18:30

Probably the most well-known outlet for tungsten alloys is the aerospace industry, where weights and counterweights are often required to be housed in restricted areas. With significant reductions in size possible, this in turn, leads to greater control of weight distribution.

Why is Tungsten Alloy Counterweights Used in Sailboat?

- Details

- Category: Tungsten Information

- Published on Monday, 15 July 2019 18:19

In some situation, we need some special things to add weight in sailboat. But the space for the special things usually very small. For example, the sailboats, if the sailboats weight is not enough, it can turn turtle easily, especially when moving in a wind weather. So, we need add some tungsten alloy counterweights into the sailboats to against the yawing when sailing forward.

Cesium Tungsten Bronze Can Be Used As Infrared Transparent Barrier

- Details

- Category: Tungsten Information

- Published on Monday, 15 July 2019 14:35

Cesium tungsten bronze (Cs0.33 WO3) nano powder is a new functional materials, which has strong absorption and high transmittance ability in near infrared region (800-1200nm wavelength) and the visible region (380-780nm wavelength). It can be used as infrared transparent barrier.

Osmotic Reaction Method to Applied Tungsten Carbide Coating

- Details

- Category: Tungsten Information

- Published on Monday, 15 July 2019 01:56

Tungsten carbide alloy has special corrosion resistance, high hardness and compressive strength. It is called modern industrial teeth and plays an extremely important role in machinery, metallurgy, precision instruments and military industries.

Synthesis Method of Levulinate by The Catalyzation of Phosphotungstic Acid

- Details

- Category: Tungsten Information

- Published on Monday, 15 July 2019 01:44

Biomass is a renewable resource with abundant reserves, wide distribution, low price and carbon fixation function. It has the potential to replace fossil resources to produce hydrocarbon fuels and chemical products. In recent years, studies have found that biomass such as lignocellulose is mainly composed of cellulose, hemicellulose and lignin. After pretreatment, carbohydrate raw materials such as cellulose and glucose can be obtained, which can be used to produce high value-added chemicals and organisms’ oil.

Tesla’s Technique to Reduce Cobalt Used In Lithium-Ion Batteries

- Details

- Category: Tungsten Information

- Published on Monday, 15 July 2019 01:27

According to Bloomberg News, Tesla CEO Elon Musk said in a conference call: Tesla has mastered the technology to reduce the amount of cobalt metal in lithium-ion batteries. The original words are: We think we can get Cobalt to almost nothing. Tesla is currently mass producing the Model 3, which is powered by a lithium-ion battery pack.

Tungsten Coating Applied on Nuclear Fusion Reactor

- Details

- Category: Tungsten Information

- Published on Monday, 15 July 2019 01:04

With the upcoming construction of the International Thermonuclear Experimental Reactor (ITER), the study of plasma-facing materials (PFM) used in ITER has become a popular and frontier research direction, as it is a key component of fusion reactor.

Fine Qualities of Tungsten Alloy in Nuclear Medicine

- Details

- Category: Tungsten Information

- Published on Friday, 12 July 2019 16:57

For many years, tungsten alloy has been the best choice for engineers and doctors regarding nuclear medicine. One key reason for this is the high density of tungsten alloy. In fact, it is more than 60% denser than lead, providing superior attenuation characteristics for x-ray and gamma radiation.

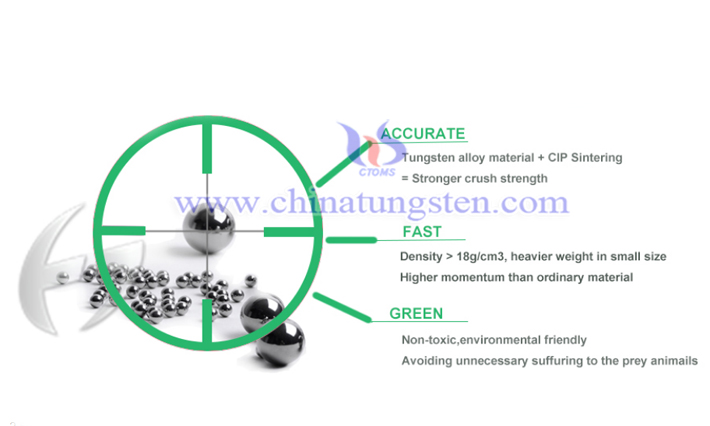

The Application of Tungsten Alloy in Hunting Guns

- Details

- Category: Tungsten Information

- Published on Friday, 12 July 2019 16:34

Tungsten alloy has been widely used in hunting guns.High density, great hardness and resistance to high temperature make tungsten to be one of the most sought-after materials for shotgun pellets in shooting history.

Facile Synthesis of a WOx/CsyWO3 Heterostructured Composite as a Visible Light Photocatalyst

- Details

- Category: Tungsten Information

- Published on Friday, 12 July 2019 16:13

Optical absorption results revealed the WOx/CsyWO3 heterostructured composite exhibits a strong absorption tail in the Vis and NIR regions which could have important implications for its photoactivity. It can be used as photocatalyst. The photocatalytic performance of synthesized samples with different Cs/W molar ratios was evaluated by the photodegradation of RhB in aqueous solution under simulated solar light irradiation.

sales@chinatungsten.com

sales@chinatungsten.com